When it comes to batteries, HYTC have emerged as the first-choice battery manufacturing partner in everything from personal electronics to electric vehicles.

The advent of the 4680 battery—a groundbreaking innovation that promises higher energy density, improved safety and cost efficiency—is set to revolutionize electric vehicle production and propel adoption. International technology giants are aggressively pursuing mass production of this "supercell," which promises to be a game changer in the automotive and energy storage industries. This has created a demand for ultra-precise manufacturing components, a demand HYTC is uniquely positioned to fulfill. Specializing in precision parts and equipment for battery production, HYTC has leveraged its expertise and adaptability to secure key partnerships with industry leaders, including supplying critical notching molds and tools for 4680 cell production.

HYTC delivers ultra-precision manufacturing capable of fulfilling diverse client requirements with expertise covering every major battery type. CEO Ben Sung says that HYTC handles the entire process from design and assembly to production and testing. “Our ability to efficiently analyze and respond to part designs, regardless of their complexity, is a key competitive advantage," he explains. There are two main types of battery manufacturing methods, winding and stacking, and HYTC produces specialized equipment for both. HYTC’s capability enables it to meet the stringent demands of global leaders like LG while also positioning them as a trusted partner in the rapidly expanding secondary battery market.

HYTC’s adaptability and expertise are key reasons for its selection by LG to partner with Hyundai for secondary battery, cutter systems and notching molds for a plant in the United States. HYTC’s ability to quickly respond to client needs was a deciding factor in an extremely competitive market. Sung describes how they recognized that traditional suppliers couldn’t supply adequate maintenance and support abroad. “We established and operated a local subsidiary in advance that can quickly respond to client demands,” he says.

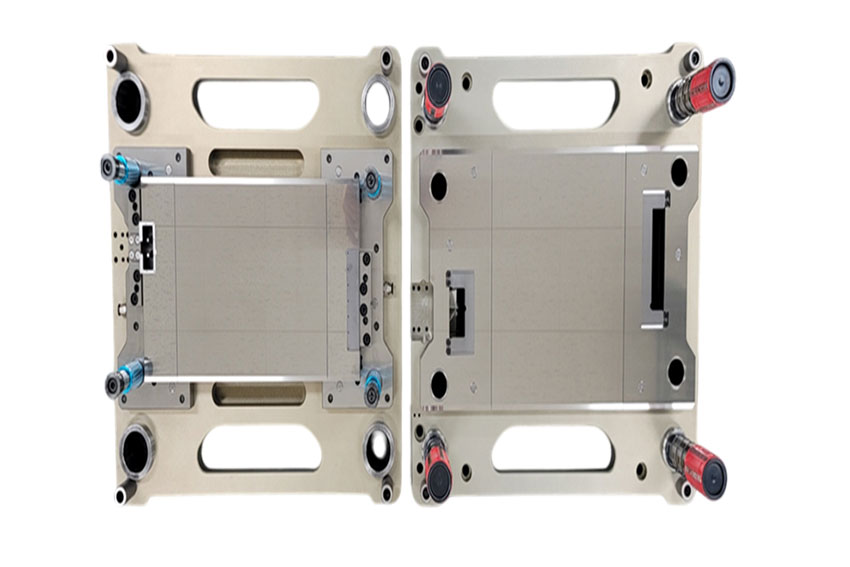

Notching Mold

Another key reason that HYTC was selected as a key partner was its focus on quality control and maintenance. In particular, notching molds need to undergo a process called “regrinding” to maintain quality. Without proper care, molds can lead to product defects and ultimately higher costs due to their frequent replacement. “By extending the mold’s lifecycle by 20 to 30 percent, we’ve been able to help our clients reduce costs and increase production efficiency,” he says.

HYTC has found success working with global clients, who are impressed by its ability to innovate at pace and be flexible to demands. In a consultation with a European client, HYTC was asked to create bespoke parts to test its capabilities. It confirmed each requirement within one minute and confirmed the part drawings in 30 minutes, vastly outpacing its competition. HYTC plans to continue to expand its global footprint and become a global leader in ultra-precision equipment parts.

For more details, explore the website at: http://www.hyseoul.com/eng/

0 COMMENTS