A leading manufacturer of pouch making machines, Totani Corporation is leading the way when it comes to developing solutions for a greener future.

“When it comes to new materials, one of the strengths we have is that we have accumulated test data going back 20-30 years.”

Ryuichi Totani, President (left), Mikio Totani, Chairman (right), Totani Corporation

Amid increased competition from regional peers in recent decades, Japanese companies have continued to excel in niche manufacturing fields characterized by high-mix, low-volume production. That is certainly the case for Totani, a leading manufacturer of pouch making machines whose in-house developed technology and after-sales service is second to none.

“What we have cherished over many years is our ability to focus on niche fields and through that, we gained a position as the number one in the global market,” says president Ryuichi Totani. “Over the past 50 years, we have developed new technologies on our own without outsourcing. What we are producing now has come as a result of that accumulated technology that we have focused on over many years.”

Totani’s reputed after sales services have been heavily guided by the Japanese spirit of omotenashi, the basis behind the nation’s famous hospitality. For Totani, the installation of its machines – which may last for 30 years or more – is not the end goal for the company, but the beginning of its service. “One of our biggest missions is to support our customers long after the sales of our machines,” states chairman Mikio Totani. “We believe the essence of our success is the success of the customer. We aim to provide a concierge-like service; we can listen to our customer’s needs in detail and resolve any problems they might have.”

As a result of this dedication to after-sales service, and thanks to the possibilities brought about by new technologies such as IoT and Big Data, Totani has developed its Data Communications System (DCS). By providing a large amount of usable data in real time, the DCS systems enables Totani’s clients to improve efficiency, track the cause of bag defects, and monitor the operation status of machinery. “When you deal with machines and operators there are always some mistakes, and this DCS system can trace back and see what happened should a mistake occur,” the chairman explains. “We are able to trace such data using this system and this gives us the ability to enhance the quality of production going forward.”

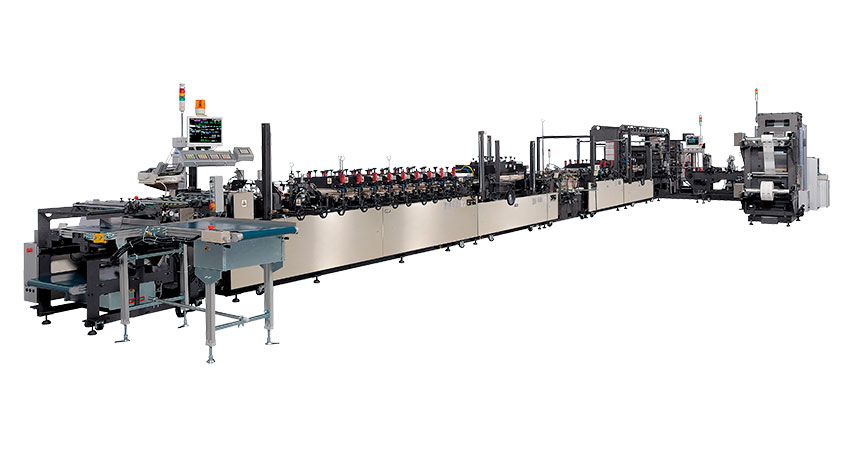

Having such a close relationship with the customer has allowed Totani to keep up with the needs of the market, such as the demand for smaller packaging and environmentally friendly solutions. The company invests heavily in R&D and harnesses the power of data to develop world-class machinery such as CT40, which can make stand-up pouches from a single film roll, whereas conventional machines required two film rolls. The advantage of the CT40 allows for high-mix, low-volume production and sudden design changes, while the machine can also make smaller-sized bags, which are in high demand these days.

Due to environmental concerns, demands are also high for Totani’s recyclable pouch making machine, and particularly from clients in Western countries. “We have accumulated special technologies to enhance productivity and speed, so with these in place, I believe that we are able to cater to the new demand for eco-friendly materials,” adds president Ryuichi Totani. “When it comes to new materials, one of the strengths we have is that we have accumulated test data going back 20-30 years.”

Thanks to the development of such machines, Totani’s sales have tripled in recent years, increasing from 4 billion yen in 2010, to 12 billion yen ($89 million) in 2019. However, profit is not the company’s only goal; so too is contributing to a sustainable society.

“We have a history of focusing on the development of new materials, such as recyclable and biodegradable materials,” says chairman Mikio Totani. “In that sense it can be said that we have been incorporating the SDGs (the U.N. Sustainable Development Goals) perspective into our management for a long time. We adopted ‘Think Sustainable’ as our company slogan and are determined to contribute to a sustainable society through our pouch making machines, while pursuing sustainable management.”

0 COMMENTS