Its excellence in composite materials and R&D marks Super Resin out as a genuine innovator.

A pioneer in Fiber Reinforced Plastics (FRP) molding, Super Resin has for over 60 years established its expertise in advanced composite materials offering one-stop solutions tailored to the requirements of its customers, including parts manufacturing for aerospace equipment, LCD/OLED and semiconductor manufacturing equipment, industrial machinery, and defense (e.g. Radar Dome).

“In addition to utilizing high-quality composite product design and manufacturing technologies, we propose optimized one-stop solutions by applying advanced design technologies that cover every stage through electrical, mechanism, and optical design,” explains Akio Asakura, President of Super Resin. “We now have over 60 years of experience specializing in FRP, firstly in Glass Fiber Reinforced Plastics (GFRP) and later in Carbon Fiber Reinforced Plastics (CFRP), and throughout our history we have tended to produce high-mix-low-volume, providing cutting-edge technologies and products to the market.”

One of the unique projects associated with Super Resin is the Expo ’70 in Osaka, the first ever ‘world’s fair’ held in Japan and Asia. “One of the symbols of the event was called The Tower of the Sun where we produced the Face of the Sun, and although it looks like it is made from concrete, it’s in fact made of GFRP,” says Mr. Asakura.

Fast forward to today and currently the company is engaged in numerous aerospace projects.

“Our business model is B2B mainly,” the company president continues. “Super Resin has two key business pillars: one is to focus on R&D, providing cutting-edge solutions, and the second is manufacturing high-quality items with thorough care.” This manufacturing activity accommodates about 70% of Super Resin’s business serving clients across industrial machinery, aviation, aerospace, and defense. Within this 70%, each of these three market segments represents approximately 33% of that total share, outlines Mr. Asakura.

“One other key up-and-coming field we are now focusing on is the energy field. This is tied with wind power generation and future power generation in particular. When I say ‘future’ I’m specifically referring to nuclear fusion. In the context of vehicles, hydrogen tanks emerge as strong candidates for both transportation and energy storage. These tanks would incorporate CFRP, and this is an area where we believe we can make a significant contribution.”

As part of this effort, Super Resin is currently engaged in a collaborative R&D effort with a well-known Japanese automotive manufacturer, focusing on materials for next-generation vehicles.

“This project is relatively small in scale, aimed at jointly developing, evaluating, and analyzing materials,” says Mr. Asakura. “But through partnerships like this, our goal is to establish a stronger presence in the next-generation vehicle industry. Additionally, we see promising opportunities in the large-size drone sector and eVTOL. We are currently conducting market research and exploring potential partnerships with companies in these fields as well.”

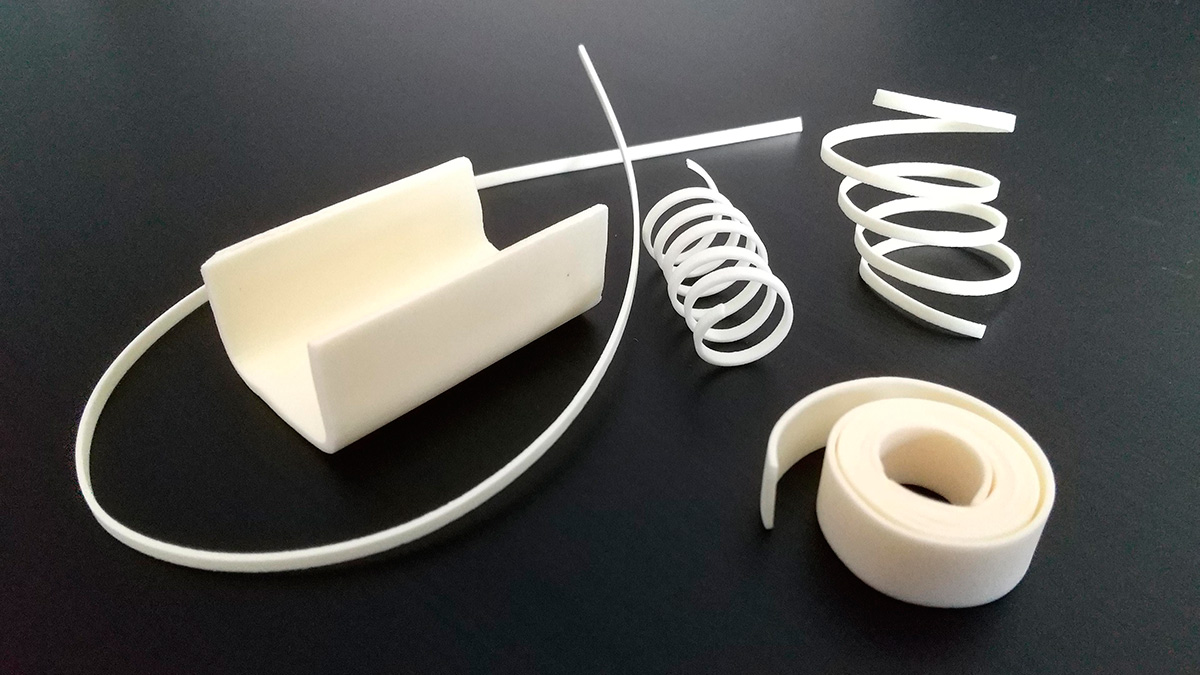

Since being established in just 2011, the company’s R&D department has since then been dedicated to the development of proprietary resins used across a number of innovations applied to diverse uses and industries. At the heart of this innovation is what Super Resin calls ‘Epoxy Foam’ technology, which enables the creation of exceptionally lightweight CFRP sandwich configuration.

“What sets this technology apart is its ability to produce thin foams right from the outset, eliminating the need for post-processing such as shaving or grinding to achieve desired thicknesses,” explains Mr. Asakura. “This epoxy foam offers the flexibility to shape 3D structures seamlessly during the initial manufacturing phase. Intriguingly, when we combine it in a sandwich structure with CFRP skin and epoxy foam as the core material, we achieve a remarkable balance of extremely lightweight properties, alongside the high rigidity and strength characteristic of CFRP. This combination results in products that are both robust and flexible, allowing us to shape them into various forms, including cylindrical shapes.”

The company also recently introduced its Glycol Lignin-containing Epoxy Resin System, a groundbreaking biodegradable epoxy resin. Glycol lignin, derived from Japan cedar, possesses two noteworthy attributes: it facilitates carbon dioxide absorption during cedar growth and boasts inherent biodegradability.

“By blending glycol lignin with epoxy resin, we reduce our reliance on oil-derived epoxy resin and facilitate the formation of CFRP while immobilizing carbon dioxide. This innovative system is also adaptable, opening up a plethora of solutions for our clients, as it can be adapted to both CFRP and foam materials, allowing for the creation of diverse shapes and forms. The development of this epoxy system underscores our commitment to transitioning from older products to environmentally friendly, biodegradable alternatives that align with our clients’ Sustainable Development Goals (SDGs).”

0 COMMENTS