Using its existing technologies as a foundation for those of tomorrow, Sintokogio has created a comprehensive support system, one that ensures the safe and stable operation of its customers’ equipment around the world.

“Through the unique blend of hardware and software, our businesses unify society and the environment, supporting the way people live and work.”

Atsushi Nagai, President, Sintokogio, Ltd.

Ever since the company was founded in 1934, Sintokogio’s corporate philosophy has been “giving form and life to process materials.” This, explains company president Atsushi Nagai, has been the guiding principle for what is the only company that has managed to automate the entire casting process, providing total solutions for foundries.

Of course, the business has had to evolve with the times, but a passion for manufacturing has driven innovation in unexpected fields, as shown with Sinto Smart Foundry™, which offers several solutions through the digitalization and connection of equipment.

“We use these connections to create smart factories that focus on quality control, a safe environment and the constant availability of machines,” Mr. Nagai says. “Focus has shifted to include the use of software with quality control with the customers’ final product in mind.”

While the business started with foundries, it has expanded to surface treatment and metalworking areas relating to engines, shipbuilding, steelwork, die casting, windmills, machine tools and robots.

“With these businesses based on our original foundry customer base, we continue to provide productivity and environmental solutions that apply across industries,” the president states. “Our electric cylinders, for example, are not only compact and precise, they also contribute to increased workability and the overall reduction of CO2 emissions on the site. We continue to provide products that respond to customers’ needs as well as the global movement for sustainability.”

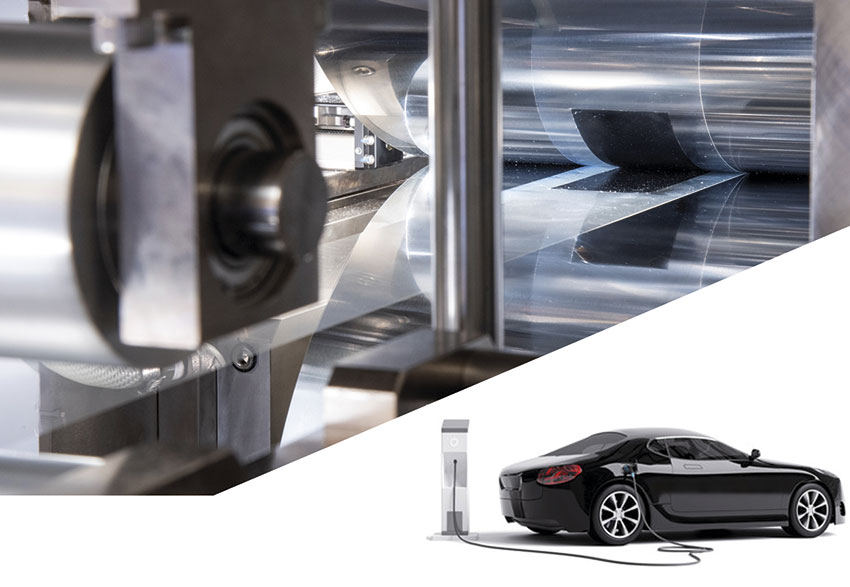

That balance between technological advancement and the environmental impact of their activities is shown in the surface treatment technologies used in the electric vehicle (EV) industry, contributing to lighter parts.

“Along with motor-related parts, our technologies are also used for next-generation batteries for EVs,” Mr. Nagai explains. “Strengthening the stacking of battery powder for better adhesion increases power and we provide processes for production to top-ranking dry-cell battery companies. In particular, Sinto is the only company in the world that can perform all these processes for all-resin batteries.”

With an aging population in Japan, the Sinto Group’s president sees an opportunity in contributing not only to the changing workforce but also to the way business is done, both domestically and globally.

“One product that supports the shifting workforce and alleviates labor shortages is our force sensor for automation, which allows robots to recreate the nuanced movements of skilled workers,” he says. “Major manufacturers like Fanuc, Yaskawa, Denso, Kawasaki and Nachi, among others, have approved our product as their official accessory.

“Now, through the partnerships and friendships that we have cultivated over the last 50 years, we will bring the force sensor and other products and services to the global market, responding not only to the demographic shift in Japan but also to changing industries around the world.”

The creation of those international partnerships are key to the future of the company, and with 40% of the 4,000-strong workforce outside Japan, this is already well underway.

“There are two types of partners we are looking for,” reveals Mr. Nagai. “Technical, to help us bring new ideas to life; and sales/marketing, to assist us in areas where we lack expertise. In Europe, the U.S. and Japan, our focus is on finding good partners in digital technology that we can combine with our technical strengths to provide the best solutions for customers.

“At the same time, we see production shifting to growing areas such as China and India, and we are adapting our original technologies to meet the local needs. Markets around the world are greatly changing, so we need to shift the product mix to meet those requirements with our key technologies, developing partnerships and promoting co-creation with local companies that allows us to reach even more customers.”

As the company edges closer to a century of business, Mr. Nagai has a powerfully inclusive objective in mind: “Our goal is for Sinto to be a career-building, life-enriching company, and I want everyone to say, ‘My life was great because I worked for Sinto.’”

0 COMMENTS