The Japanese firm Pantech has established itself as a leading provider of plastic recycling services, working with partners in Japan and overseas.

“Pantech seeks the greatest possible benefits for itself, waste-producing companies and partner plants, in order to contribute to society and sustainability.”

Masaaki Kuroki, President, Pantech Co., Ltd.

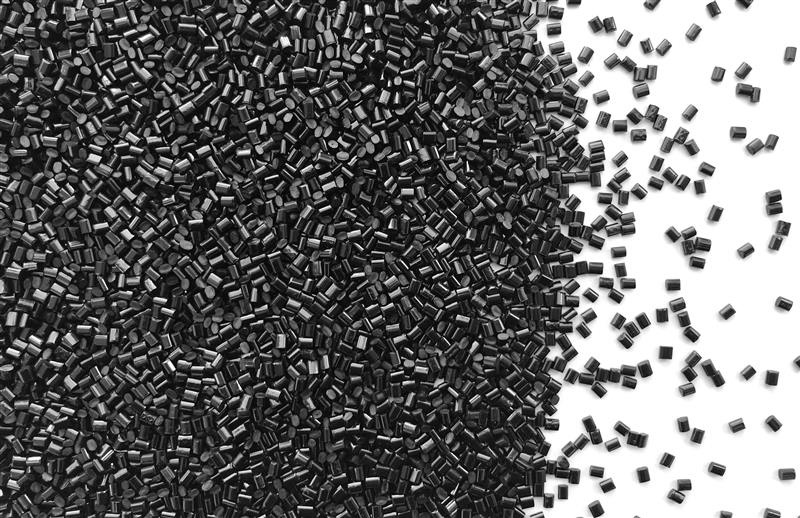

Established in 1996, Pantech is a Japanese company that provides comprehensive waste plastic recycling services. It specializes in collecting plastic scrap generated by the consumer goods industry, before converting it into recycled plastic raw material and distributing it domestically and internationally.

“Plastic has a lot of different types, from general purpose resins such as polyethylene terephthalate (PET) and polypropylene (PP), all the way to engineering plastics such as carbon-fiber-reinforced polymers (CFRP),” says Masaaki Kuroki, Pantech’s president. “There are many kinds of plastic waste, so we have developed various solutions for the collection of these different plastics.”

Based in Otsu City, Shiga Prefecture, Pantech is a fabless company, working with partner recycling factories both in Japan and overseas. In all, the firm currently boasts a network of some 50 partner recycling plants – a total that is always rising. “As we increase the number of partnerships we have, we can also increase the volume of recycling that we can do,” Mr. Kuroki notes. “This will grow our business and lead to further contributions to the environment.”

At the heart of everything Pantech does is a dedication to Sanpo Yoshi – a corporate philosophy that has been the company’s credo since day one. “Sanpo Yoshi means creating benefits for all three sides,” Mr. Kuroki explains. “Pantech seeks the greatest possible benefits for itself, for waste-producing companies and for its partner plants, in order to contribute to society and sustainability.”

Ultimately, the company’s goal is to help achieve a circular economy – in line with the Sustainable Development Goals (SDGs) established by the United Nations – in which materials are recycled and reused, and waste is kept to an absolute minimum. “To realize this vision, though, it is essential to adopt a circular design process that considers the product’s recyclability before it is manufactured,” Mr. Kuroki says. “Of course, product design change is not easy, but Pantech provides companies with extensive circular design support throughout the research and development process.” Pantech will open its Circular Design Center (CDC) this year on December 8th in order to comply with the increasing quality demands of the global market.

In Japan, Mr. Kuroki continues, there is a growing sensitivity to the importance of recycling and the need to improve products’ recyclability. “Japanese people have been raised on mass consumption and mass production, which in turn has resulted in mass waste,” he says. “And the Japanese emphasis on superior quality means there is a proclivity to produce intricate materials or products that amalgamate diverse materials. This complexity can lead to products that pose challenges in recycling. In 2021, however, the Japanese government gave people the opportunity to reflect on how they use plastic and I think now, slowly, Japanese manufacturers are becoming more aware of just how vital plastic recycling is.”

Crucially, manufacturers are increasingly open to teaming up with organizations like Pantech, Mr. Kuroki says: “We have seen a growth in opportunities to work with the people in the development departments at companies that produce waste. By working with those departments, we have been able to come up with solutions.”

Internationally, Pantech has a history of working closely with recycling partners overseas – and as the company seeks to strengthen the already significant impact of its activities, it is targeting new alliances right across Asia. “Up until 2017, more than 80% of recycled plastic generated in Japan was supported by global demand, so because of that we have a lot of partners abroad,” Mr. Kuroki reveals. “Actually, you can find a lot of companies overseas, especially USA and EU, with advanced recycling technology, far better than those found in Japan. This is why we have a lot of partnerships for technology all over the world for plastic recycling.

“Moving forward, we would like to promote even more cooperation with Asian countries, particularly in the Association of Southeast Asian Nations (ASEAN) region. If we look at commodity production, a lot of Japanese companies have moved their production sites to other Asian countries, and 50% of European plastic production is now done in Asia. We believe a focus on the production of recycled products is needed throughout Asia more than any other region. There is a lot of potential in this region for recycled products.”

0 COMMENTS