Komatsu Industries Corp. provides its best-in-class machinery and after-sales services to automotive makers, while leveraging IoT to champion predictive maintenance technologies.

Guided by its “Quality and Reliability" philosophy, Komatsu Industries Corp. serves an indispensable partner for manufacturers in the automotive, construction and home appliance industries, supplying industrial machinery built to the highest quality and made to last. A pioneer of technologies such as its servo press, the Japanese company is today providing state-of-the-art machinery supporting the development of the automotive industry and manufacturing-based IoT applications.

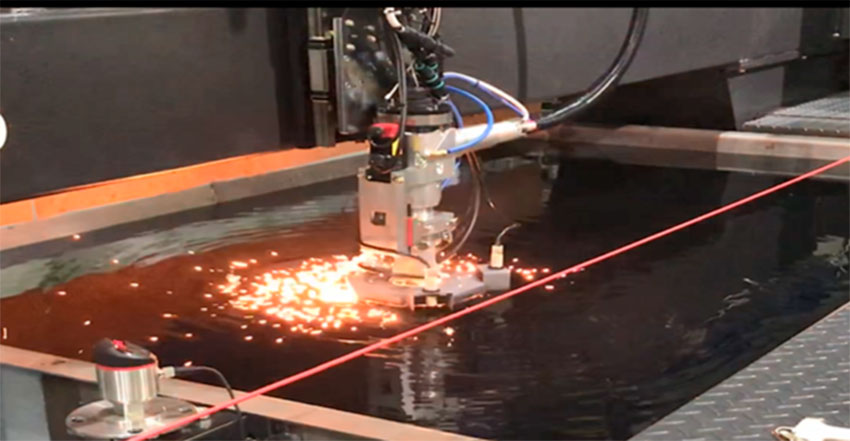

Aside from press machines, the company has focused on laser technology, developing fiber-laser cutting processes that enable cutting to be done in water, which will result in reduced environmental impact and ensure energy savings for customers.

With the emergence of electric vehicles (EVs) that require lighter weight materials, high-tensile steel has been in high demand. In response, Komatsu has developed a laser cutting machine that trims the press-formed parts of high tensile steel. “Our TLH 3D laser cutting machine is the best solution for trimming hot-formed parts,” says president Yasushi Kitade.

Meanwhile, the evolution of cold forming, which requires less energy consumption than hot-forming, bodes well for an automotive industry looking to lower its carbon footprint. “Amid the carbon neutrality trend, product development has led to cold-formed high tensile steel having gained almost the same strength as hot-formed without hot forming,” explains Mr. Kitade. “Komatsu has been developing suitable press machines with our customers for cold-formed ultra-high tensile steel.”

He adds: “The quality of EV vehicles is oftentimes determined by the distance it can run and operate, but at the same time, the design aspect is crucial, so we are now talking with automotive companies about the strengths of our servo press, which can do so many things at once. Our products are long-lasting, so it is crucial that we provide long-lasting maintenance service and retain good relationships with our customers.”

As it strives to provide long-lasting maintenance, Komatsu has leveraged the strength of IoT technology to develop its predictive maintenance services, which is helping clients to increase the productivity and efficiency of their manufacturing operations.

“We have a predictive maintenance system incorporated into each machine in order to keep staff up to date on the machine's health,” says Mr. Kitade. “There are many components in each piece of our machinery, and each component has a prediction on its lifespan. We are analyzing and taking data on each component to determine its longevity. There are many different customers, and as such, each customer takes their approach to our machinery a little differently. Some customers keep spare parts for our machinery and do regular replacements, whereas some do not. We are trying to use this system to urge our customers to do predictive maintenance and parts replacements.”

In terms of its global operations, Komatsu Industries Corp. has eight overseas subsidiaries located nearby automotive manufacturers’ plants. In the U.S., it is approaching car makers buying up old Japanese automotive factories to transform them into EV plants. “We have been approaching these companies since we have experience providing services to these existing Japanese factories,” says the Komatsu Industries Corp. president. “Globally, there are new emerging EV companies, so we are also approaching them so that we can increase our sales channels.”

As the company presses ahead with supporting a new era of manufacturing, Mr. Kitade stresses the importance of the company’s commitment as a long-lasting partner. “What is important in manufacturing is providing the products and service, and there has to be a balance between the quality of the product and the after-services added on top. We wish to keep our business growing by providing this comprehensive solution to our customers.”

0 COMMENTS