From the invention of a revolutionary hydraulic lathe to the development of leading-edge pick-and-place machines, Fuji’s pursuit of innovation has been present throughout its history.

A company guided by its corporate message “innovative spirit”, Fuji Corporation is a major Japanese supplier of electronics manufacturing equipment, boasting locations across the globe. The 64-year-old firm specializes in robotic pick-and-place machines, which are used to mount electronic components on printed circuit boards – a process integral to the production of widely-used technology such as smartphones.

“Back in 1959, company founder Mamoru Sakagami invented a revolutionary hydraulic lathe suited to mass manufacturing, which contributed greatly to the growth of the Japanese automotive industry,” says Fuji President Nobuyuki Soga. “At the time of development, he faced resistance from people who thought his idea was not applicable, but he continued to make efforts and completed the machinery. That spirit of pursuing innovation still remains in our company – it’s a core value for our employees.”

Among the leading-edge pick-and-place machines that Fuji supplies to the surface-mount technology (SMT) sector are the best-selling NXT and its successor, the NXTR, which is expected to be a big hit in 2023. Incorporating the latest advances in robotics, they guarantee high-speed, high-quality placement, and can mount electronic components for a wide range of products.

The AIMEXR, a pick-and-place machine whose creation was announced at the end of 2022, also offers excellent versatility – a quality that’s more and more important to electronics manufacturers. “Electronic circuit boards have been increasingly diversified,” Fuji said in a statement in December. “In addition, globalization has brought instability in supply chains. These trends require more flexible production support at manufacturing sites.”

Meanwhile, another example of Fuji’s state-of-the-art manufacturing technology is the FPM-Trinity, a quick, efficient electronics 3D printer capable of resin printing, circuit printing and component mounting. Its development is illustrative of the firm’s commitment to playing its part in a greener future. “We’re out to reduce the environmental impact of our business activities and contribute to a sustainable society and environmental conservation,” Mr. Soga explains. “The FPM-Trinity has near zero waste liquids, etc., and we believe it’ll be a promising device in the future from the perspective of the Sustainable Development Goals.”

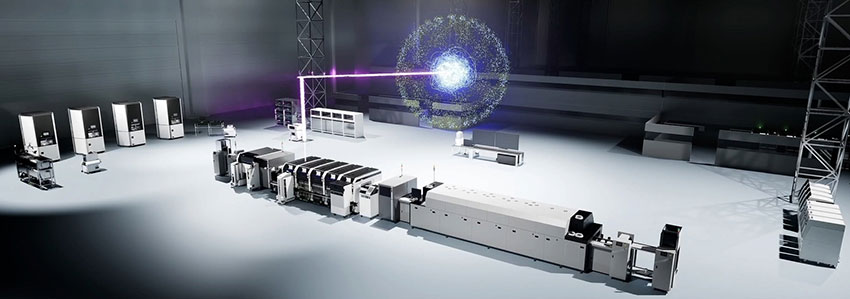

In addition to supplying individual pieces of manufacturing equipment, Fuji offers technology that can optimize entire SMT production processes. Harnessing IoT, Fuji’s smart factory solutions allow clients to maximize quality and productivity by linking up manufacturing machinery and systems so they can share data with each other. Armed with this information, companies can more easily complete tasks such as scheduling, part management, systems maintenance, defect assessment, and production analysis. And, thanks to automation, many such processes are carried out automatically.

“If you’re a global company, you have to control the production system globally,” Mr. Soga says. “Which products are made when, where and in what quantity – that’s vital information. Increasing production efficiency is important. Our smart factory solutions combine all the latest technology to provide a solution for our customers. You have to be at the forefront of cutting-edge technology, or you will lose in this industry.”

0 COMMENTS