Yamashin Filter Corporation leverages proprietary nanofiber technology to deliver high-performance filtration solutions across construction machinery, industrial applications, and healthcare sectors worldwide.

By Sasha Lauture and Bernard Thompson

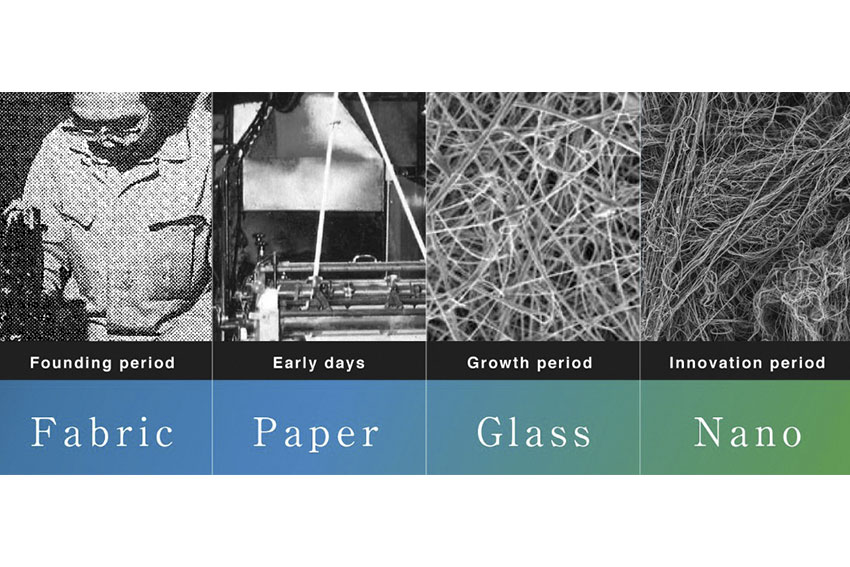

Yamashin Filter Corporation, established in 1956, stands as a trailblazer in the filtration industry and is proudly listed on the Tokyo Stock Exchange's prime market. Renowned as a Tier 1 manufacturer, Yamashin dominates the global market for hydraulic filters in construction machinery, delivering high-quality solutions to industries worldwide. Unlike most competitors who rely on external suppliers for filter media, Yamashin’s unique strength lies in its end-to-end expertise—developing and manufacturing proprietary filter media that drive unparalleled performance. This innovative approach has solidified Yamashin's position as a leader, shaping the future of filtration technology.

In 1978, Yamashin revolutionized the filtration industry by becoming the first company globally to use glass fiber as filter media, establishing a de facto standard in the field. Now, Yamashin has taken a bold leap into the future with its groundbreaking "Yamashin Nano Filter®," a next-generation filter media crafted through a proprietary nanofiber manufacturing process. This patented innovation stands out with its ultra-fine fiber diameter and exceptional porosity, setting it apart from conventional fiber-based materials.

In hydraulic filters for construction machinery, Yamashin Nano Filter® delivers an impressive three to four times longer service life compared to traditional glass fiber filters, earning widespread adoption by leading construction machinery manufacturers. In air filtration, the Nano Filter excels further, powering MERV14-certified products sold in Japan through its Group company, AQC Corp. These advanced air filters not only surpass the MERV13 standard, the pinnacle for building air conditioning, but also highlight Yamashin’s commitment to pushing boundaries in filtration technology.

Yamashin Nano Filter® is revolutionizing the filtration industry with its cutting-edge nanofiber technology, now offering advanced solutions for global air filter manufacturers. The series includes NanoWHELP™, designed for MERV 14-15 class air conditioning filters, and Yamashin Nano Air™, engineered for HEPA and Semi-HEPA applications. These innovative materials not only deliver superior filtration performance but also address critical environmental and regulatory concerns.

The filters significantly reduce energy consumption—up to 23% in air conditioning systems—thanks to long-lasting, low-pressure drop technology. Their extended service life minimizes waste, contributing to lower CO₂ emissions. Free from PFAS, PFOS, and boron, these filters meet global safety standards and are perfectly suited for clean room environments, particularly in semiconductor manufacturing.

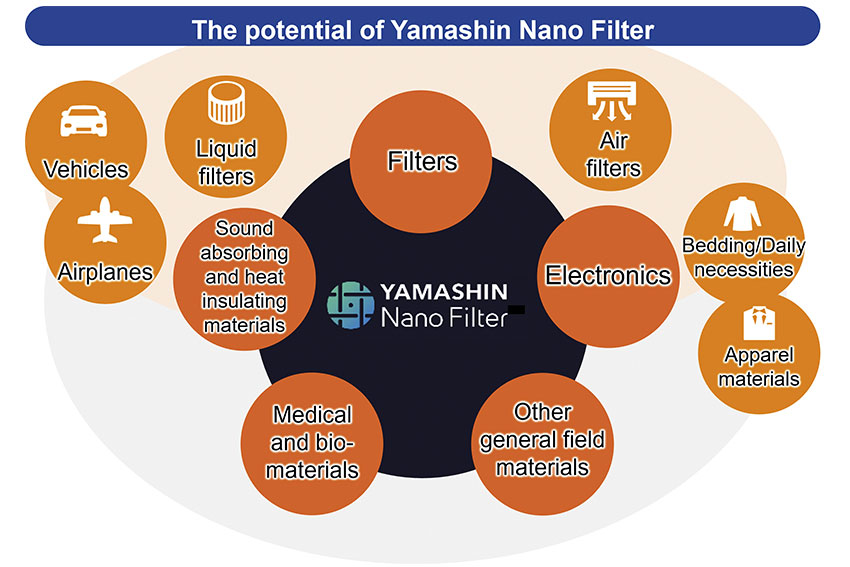

Yamashin Nano Filter® stands apart with its high porosity, ultra-fine fiber diameter, and flexibility in raw material selection. Beyond filtration, the technology offers immense potential for diverse applications, including heat insulation, heat resistance, and conductivity. Yamashin is actively seeking partners for technical collaboration, specification development, and sample evaluations to bring these groundbreaking innovations to market.

In the field of heat insulation, Yamashin is pioneering advancements by selecting innovative resins for apparel and bedding wadding, enabling the creation of thin, lightweight products with exceptional heat insulation. By incorporating moisture-absorbing and heat-generating properties, these materials can achieve superior heat retention, redefining comfort and efficiency. Leveraging advanced melt-spinning technology with highly heat-resistant resins, Yamashin is setting its sights on the transportation and fireproof clothing markets, offering cutting-edge heat insulators with unparalleled heat-resistant functionality.

In terms of "conductivity," in addition to the excellent flexibility, air permeability, and light weight of "Yamashin Nano filter®" itself, we aim to use it as a wearable sensor by acquiring conductivity through various methods including the coating of conductive polymers. If we can add even higher conductivity, we are confident that we can provide a product of an electromagnetic wave shielding material that also has heat resistance and sound absorption, and that can replace similar products currently available in the market.

Yamashin invites inquiries and sample requests from innovators seeking cutting-edge solutions with Yamashin Nano Filter®. Designed for air filtration, heat insulation, heat resistance, and conductive nonwoven fabrics, this revolutionary material unlocks new possibilities across industries. Explore how Yamashin Nano Filter® can transform your applications—connect with them through the link below to learn more and request samples.

For more information please visit: https://www.yamashin-filter.co.jp/eng/form.html

0 COMMENTS