Tsuchiya Kogyo uses a broad spectrum of techniques to convert concepts into tangible products, such as durable decals, molded parts and emblems for a wide variety of applications, including the automotive industry, home appliances, railways, and theme parks.

It is an exciting time for Japanese manufacturing. The past three years have seen large supply chain disruptions due to COVID as well as the US-China decoupling situation, and as a result, corporate groups are looking to diversify their suppliers for reliability reasons. Known for their reliability as well as their advanced technology, Japanese firms are in an interesting position. Combined with a weak JPY, many observers argue this is a unique opportunity. Do you agree with this sentiment, and what are the advantages of Japanese firms in this current macro environment?

We feel that as a Japanese company, we are currently in an advantageous position. In recent times, we have seen many Japanese manufacturers relocating their production sites from China to Japan. In recent years, Japanese politics, society, and technological foundations have been stable. Due to deflation and labor salaries remaining the same, it has become easier for both Japanese and overseas companies to manufacture in Japan. The depreciation of the JPY has also made it easier for Japanese companies to export their products. These factors combined with the high levels of technology possessed by Japanese companies, have put them into a very advantageous position at this time.

Our uniqueness is that we work with a variety of products in many different industries. We are able to combine our accumulated know-how with our past experiences in these different industries to provide the optimal solution to each specific customer. Our strength also lies in our costs. By leveraging our accumulated knowledge, we can provide a less costly service to our customers when compared with our competitors.

Japan is the oldest society in the world with a rapidly shrinking population. The side effects of this include a labor crisis and a shrinking domestic market. What have been some of the challenges that this demographic shift has presented for your firm, and how have you been reacting to it?

Japan’s demographic decline is indeed posing a threat to labor security in Japan. However, the rapid evolution of AI in the past couple of years has helped us to increase the efficiency of our business operations. With that, we have not seen an immediate downturn, especially as more assignments and projects are coming back to Japan from China, as Japanese companies relocate their manufacturing bases. We also recently learned that there are many Europeans and Americans who are interested in Japanese culture and are willing to work in Japan. Diversifying and opening up new job opportunities not only to Southeast Asian workers but also to international people for management roles, will help our company to remain sustainable and continue to grow.

The international personnel who are willing to work for our company or other Japanese companies are those who are interested in Japanese culture and the Japanese working style. This makes it easier for them to adapt and work in the Japanese style.

We are also expanding our factory in the Philippines, which has abundant labor resources, and are focusing on making industrial parts aimed for exports, while at the same time utilizing Japanese technology and maintaining strict Japanese-style quality control.

We know that your products are used in a variety of different applications including the automotive industry, home appliances, railways, and even theme parks. Which application are you currently focusing on, and are there any new applications or industries to which you would like to introduce your products?

Our technology lies in converting 2D drawings into 3D, for automobiles or houses for example. We have accumulated our know-how over many years and want to continue to strengthen these areas by providing our services to various industries. With regard to the automotive industry, the longevity of the inside of the engine and its functionality has been extended. Especially concerning car wrapping, caution labels, and decals, however, there are limitations to their paint’s wearability. In the future, once the paint wears, we will take the car and renew the paint on the surface. That is one area of our business that we will be focusing on.

The automotive sector is currently going through a once-in-a-lifetime change with the switch from gasoline vehicles to EVs.This switch means that newer specifications are required, with the internal combustion engine being replaced with the lithium-ion battery engine. As this switch to EVs continues to take place, what opportunities do you see for your firm to take advantage of?

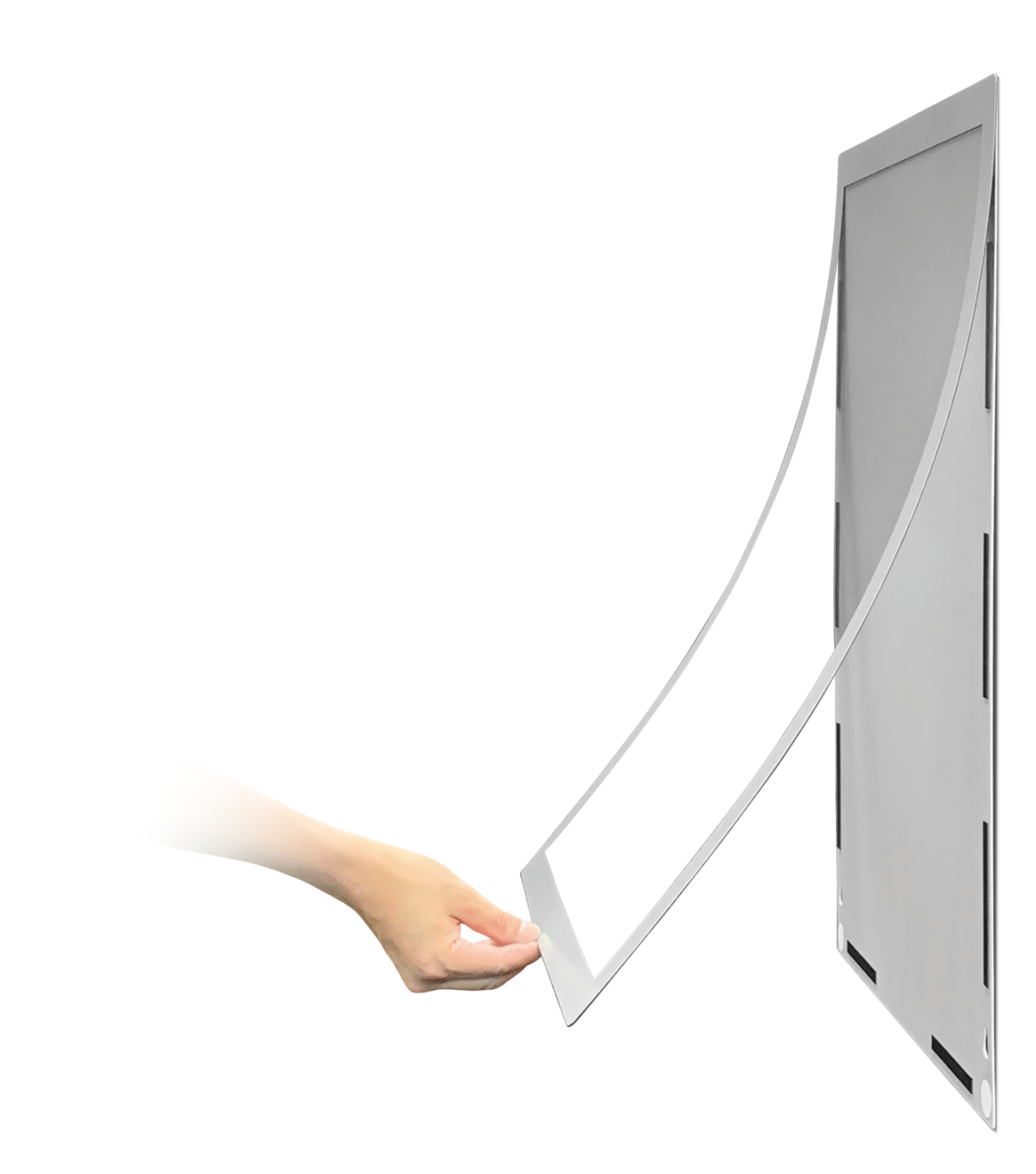

We are currently in the process of setting up a new business to produce a lightweight plate that is applied to the interior of cars. By changing the way light passes through the plate, the appearance of the surface changes and what type of letters can be seen. This display is lightweight and requires minimal electricity to operate. It is best applicable to EVs.

Depending on the direction from which the light passes through the panel, different patterns can appear. For instance, the plate can change from being completely invisible (no light) to pattern A, to pattern B depending on the direction of the light. It can switch between transparent and two patterns. It is relatively simple and cost-effective and can be used for HUDs or similar applications. It can also be used as overlay for touch panels.

Switchable light guide plate

Your main business has been behind the scenes in terms of manufacturing. However, you have also started developing label cutters for B2C applications. What was the motivation for starting this business, and what is your strategy going forward to increase your branding and promotion of this product?

Our company has a well-established structure that allows for the ideas of our employees to be realized. One unique aspect of our company is that our employees can invest in these new ideas, which means that if the product sells well, our employees can reap the rewards. The risks and the benefits are shared between the company and our employees, and these potential benefits help to motivate our employees.

The reason for the creation of our original product, the Label Cutter, was that I had heard from one employee that their family members were arguing about who would have to peel off the plastic labels on PET bottles for recycling. This led to me coming up with this idea. It is still in the development stage right now as we are working on improvements. Japan is strict about garbage separation and everybody must abide by the policies that are in place. Therefore, we are trying to make it as easy as possible.

In addition, our company's pioneering product in the B2C segment, a time-saving poster frame called Poster Fit, has gradually penetrated the market over the past 10 years and is now used at post offices, large supermarkets, and electronics stores nationwide. Sales have been increasing through online orders and are expected to keep growing from here on as well.

Can you tell us a little more about the R&D strategy and are there any new products or technologies that you are working on?

We are putting our emphasis on creating a cycle of environmentally friendly products. At the same time, recycling products for reuse is very important for efficiency. There is always waste when you make a product. Recycling this waste is important too.

During the Covid-19 pandemic, there was an increase in the use of face shields and other hygienic products such as films, which you provided. During that time, the market was completely flooded with similar types of products. What differentiated your products and made them stand out when compared to more conventional ones?

Our strength lies in our manufacturing capabilities for forming and molding. We cut the sheets and shape them in the most efficient way, and we are capable of mass-producing them at a low price. This gave us an advantage over our competitors in the market.

We have also developed and sold an invisible protective face shield that utilizes a special ultra-low reflection film, which continues to be well received.

We know that one challenge many molding companies face is the occurrence of burrs, which are unusual protrusions that can impact product quality. When it comes to your products, how are you overcoming these burr challenges?

The kaizen philosophy is a common standard in Japanese factories. The workers understand the need to make improvements to overcome specific issues. Burrs are one of the issues that our workers make efforts to overcome to ensure the high quality of our products. Burrs are inevitable in the production phase. Our workers use automated machinery to remove the burrs before our products are released to the market.

We saw that you recently participated in Comic Market (Comiket 102) for the first time. Could you tell us more about your time at this event, and did it meet the expectations that you had going into it?

We recently exhibited at the anime comic market event Comiket 102. The reason for attending was that we are planning to target the Otaku genre with our products. We also have many clients in the field of pachinko and slot machines. We possess advanced graphic design and car wrapping capabilities and wanted to showcase these capabilities by displaying an anime-themed car. We even came up with an original character for the car wrapping. Many people were interested in our technology. We also showcased our screen-printing and molding technology on pachinko machines featuring famous series such as Gundam and Sword Art Online. Through our displays, we were able to stir curiosity among the people. Many of our clients are also Otaku and we shared tickets with them as tickets for the event were difficult to come by.

The trend in the animation world right now is digital. When we exhibited, the major companies around us were mostly using digital booth displays, however, ours was strictly analog. We wanted to emphasize the uniqueness of analog through our exhibition. We collaborated with two pachinko makers for the event and displayed their pachinko machines at our booth, which in addition to us selling merchandise, helped cover the participation costs. One of our partners also unveiled a still unreleased pachinko machine at the event. This stirred interest on social media and was a highly cost-effective PR strategy for both us and our partners.

I did not previously know anything about the otaku genre, so that is why we were able to come up with something new for our booth. When we were planning for the exhibition, I realized that a lot of our employees are otaku including many of our intellects. I was amazed to see their extensive knowledge.

Japanese animation is also popular overseas. There are many international festivals in countries such as the US and Australia for instance. Is participating in these international events an area of interest for your firm as well?

We currently work behind the manufacturers. However, when it comes to the overseas markets, going forward, we want to create our own products and work directly with the customers. Our attendance at Comiket 102 was a good lesson for us on how to penetrate the otaku market not only in Japan but possibly overseas as well.

You mentioned earlier that you collaborated with a pachinko machine maker. Are you currently looking for overseas partners to develop new products and services to cater to these new markets?

Yes, we are actively seeking overseas partners. We are currently looking for distributors to sell our products, especially for our automobile-related inventory. We want to send the parts that are produced in Southeast Asia and Japan to their locality and delegate them to carry out the sales. These kinds of logistics will be crucial to supply local automakers.

We know that since 1991, your company has been present in the Philippines, and you have since expanded to locations such as Thailand and China. Moving forward, which countries or regions do you believe will be key for the corporate growth of Tsuchiya and what strategies will you employ to do so?

We have factories in two locations in the Philippines. Right now, the Philippines is a good place to have a factory as the country is currently experiencing economic growth as well as a population boom. Another advantage is that exporting from the Philippines to the US is easier as there is no language barrier. This is important for us as we are currently focusing on the US market. One of our clients is located in Georgia and we are considering establishing a sales office in the area close to our client. That is part of our international business strategy going forward.

We also want to focus on countries where the population is growing such as India and Vietnam. It is important to contemplate how competitive we could be in each of these markets. With regard to China, we closed down our bases there five years ago. In the past, we collaborated with a Taiwanese company in China. However, we are concentrating our production bases in Southeast Asia and Japan for now.

Imagine that we come back five years and we have this interview all over again: What are your dreams for this company and how would you like to be seen in the global market?

Going forward we want to emphasize developing original products for both the domestic and international markets. That will be a key focus for us in the future. Another important business pillar that we want to grow is our automotive car wrappings and car graphics. Our strength lies in designing and manufacturing the actual wrappings. One way to increase their popularity would be to create an online competition for designing the wrappings. We anticipate that many designs will be submitted by the users. We want to take these designs and create a pattern that is applicable to specific types of cars and then sell these designs globally. We believe that this will increase the overall global demand for such products. In Southeast Asia, where cars are considered high-end, people decorate their cars to make them more original. We intend to create graphics that are approved by automotive manufacturers so that the price does not drop when the car is sold second-hand. In addition, my future goals are to hone our exterior-related know-how and to develop new products and markets.

Interview conducted by Karune Walker & Sasha Lauture

0 COMMENTS