The interview delves into the current landscape of Japanese manufacturing, focusing on the opportunities and challenges faced by companies like Yuasa Yarn Guide Engineering. It highlights the necessity for supply chain diversification in light of policies like the US Inflation Reduction Act, emphasizing Japan's reliability, advanced technology, and favorable currency exchange rates.

Right now, is a pivotal time for Japanese makers. Policies like the US Inflation Reduction Act are forcing corporations to diversify their supply chains for reliability and to reduce country risks, with nations such as China. Japan is known for its reliability, advanced technology, and a weak JPY, so for the time being Japan has never been a more cost-effective option. This means that Japanese firms have an opportunity to expand their existing global market shares. Do you agree with this sentiment, and in your opinion, what do you believe to be the advantages of Japanese companies in this current macroeconomic environment?

As far as overseas operations, we are mainly dealing with the Chinese market and other parts of South Asia. This business is conducted through a local agent so our product demand fluctuates based on how much production is made in China. Two years ago we had record-high sales with an increase in yarn production in China, the biggest leap since the beginning of the 21st century.

We believe our company is a similar case to textile machinery manufacturers, where the demand for machinery is based on the demand for Chinese yarn manufacturing. Likewise, two years ago they also reached record highs but now the demand has dropped quite considerably. For our case, we consider the situation slightly different, as two years ago was the peak but now demand has returned to normal. Reflecting on the peak period, if we were able to produce more we would have enlarged our sales channels even further, however, there was a limited supply of raw materials there was a mad dash from every company to procure those materials, thus there was a ceiling to the potential growth that could have been achieved during that time. With the idea of another surge occurring at some point in the future, we want to prepare ourselves and diversify our supply chain so that we can maximize our production and sales.

You mentioned both the Chinese and Asian markets, and you also mentioned the limitations. When we interviewed other key players in the industry we’ve always heard about the importance of partnerships and open innovation with local partners. What role do partnerships play within your business model and are you currently looking for any new partnerships in overseas markets?

In China, we have a very good relationship with our representative agent. During the COVID-19 period, we weren’t able to dispatch our people, but usually, we dispatch sales personnel and technicians over to China ten times a year to promote our sales.

You mentioned that China is the center of your attention but we also know that from Japan you have established a network in over 20 different countries. What other locations would you like to continue your expansion in for the foreseeable future?

We have a record of selling to over 50 countries worldwide, an impressive feat I’m sure you will agree. We have a showroom that displays the products that we have exported overseas. Among these 50 countries, we are of course, mainly focused on China but at the same time in order to diversify we are working together with a trading firm that takes care of the Korean, Indian, and other Asian markets.

Emerging nations that we are focusing on include India and Bangladesh since both of these markets have ballooning populations, with India recently surpassing China in terms of population. These markets are attractive in terms of textiles, although, in the past, we did attempt to conduct sales in India without much success. Even exhibiting in Shanghai hasn’t led to concrete sales despite numerous Indian visitors. We still need to find an effective approach to the Indian market.

We see huge potential in the diversification of the application of our products. Currently, 36% of our clients are from the apparel and textile industry, 8% are from industrial textiles including wires, and 2% are from the sanitary industry. Increasing sanitary and industrial is something we are pushing for. The remaining 53% is accounted for from business done by overseas trading firms, but unfortunately, we aren’t clear on what the exact breakdown of industries is for those overseas sales. Despite this, we are sure that by working with local agencies we will be able to approach new areas and increase sales through diversification.

Over the last 25-30 years Japan has seen a rise in regional manufacturers from countries like China, Korea, and Taiwan, who have replicated the Japanese model for success but done so at a cheaper labor cost. Nevertheless, Japanese companies still maintain high global market share, particularly in niche, B2B. With that in mind, what do you consider to be your main competitive advantages that appeal to prospective clients both in Japan and overseas?

The strength of our company is the quality and assurance customers get in terms of that quality. Our products are reliable and that is assured through strict inspection procedures.

We do not skip the inspection process to cut down the delivery times. We never compromise on quality.

Our products may be considered more expensive than other products, but due to reliability our customers still choose us time and time again.

There is also a comprehensive service element to what we offer to our clients. Sales personnel will listen to the requirements of customers and then we can adjust our solutions to fit their needs. Aftercare service is also something we highly value.

Your company was founded back in August 1924, and this year will mark your 100th anniversary. Starting with the manufacture of silk and linen you have now expanded to offer a wide range of parts for textile machinery. Could you highlight for us what you consider to be the key milestones of your company’s history? What have been some of the main products that have helped establish and grow your company into the reliable partner in the textile industry we see today?

As you said in your question, our company was established in 1924 by my grandfather, and from its establishment, the company provided textile machinery parts and components. We would release a catalog regularly explaining how to use those products and what product ranges were available.

When it came to my father’s generation the work got very busy. My father had eight siblings and he was the oldest, and it was the three sons that my grandfather called to work for the company. Eventually, the fourth son was also called as well as the fifth son who was about to enter university. The company became so busy that it was all hands on deck.

As the business got bigger and bigger, constant improvements were made to the products we offered. At that time steel was used to make our products, so to make steel parts last longer we decided to establish a hard chrome plating factory. The owner of the land was a farmer and he said that if we wanted to open a factory on the land, he would be willing to sell the land to us. Nowadays our headquarters is on this land, which was the premises of our hard chrome plating factory, established in 1963.

I think that a core strength of our firm is our ability to provide the best service that is suited for each type of yarn and thread. Surface treatment for example is better suited to some yarn than it is for others. These technologies are something that we’ve accumulated over many decades and speak to our company’s ability to hold its head high. We are constantly trying new ideas and trying to incorporate new technologies within our product lineup.

We started the company as “Yuasa Shoten” (Yuasa store), so when you count back the history, “Yuasa Shoten” goes back 100 years, but with our current name, our history goes back to 1963 since that was the year we established Yuasa Yarn Guide Engineering as a manufacturing division and also the year we launched a hard chrome plating factory.

One of your signature products is your INTER LACER, a device that wraps fibers together by pushing compressed air out of a nozzle. How is the INTER LACER overcoming some of the challenges that come from dealing with synthetic fibers? How is the INTER LACER superior to more conventional products available?

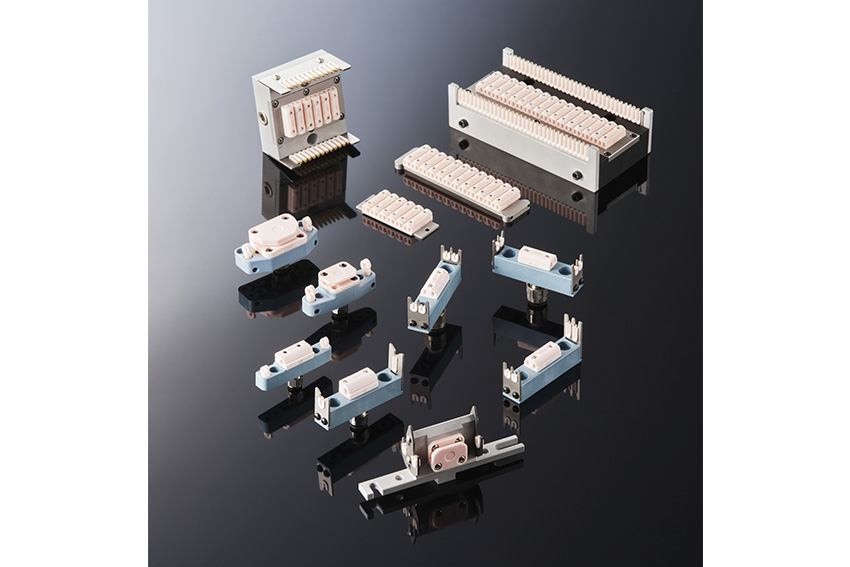

We have been putting a lot of effort and thought into this product. Interlacers themselves are a very complicated system and I think that our company can stand out since we have a variety of them. Depending on the type of material of the yarn and the thickness of the yarn we can propose the best-suited type of interlacer.

The textile machinery industry is in a perpetual state of evolution, constantly generating new technologies and processes. This dynamic environment offers amazing prospects for both newcomers and long-time players to engage in the latest innovations and become frontrunners in textile production. How is your company adapting to these rapid changes in technologies? What products are you offering to cater to these growing needs of new machines that are entering the market?

The digitalization of our parts and components is something we are actively pursuing. We not only provide yarn guides but also guides that apply tension to the yarn. Additionally, we provide straighteners and sensors that detect knots in the yarn. This industry traditionally has been very analog, for example, control might be done with a knob that doesn’t have a numerical value to guide the operator. Years of experience are necessary to determine the required amount of tension to produce the best type of yarn. Many companies are pursuing digital tools to make the operation of these machines easier, but we want to make them more affordable and reachable for general usage. To that end, we are trying to add digital tools to analog systems. In fact, for the past two years, we have been exhibiting our digital products at exhibitions and we are currently in the testing phase for our newest digital features.

Japanese companies are widely known for their ability to develop new products to serve the needs of society. In recent years, you released your new Oiling Guide as well as a new Twist Stop Wheel. With these new product launches in mind, what is the current focus of your R&D strategy? Do you have any new products or developments that you would like to showcase for us today?

Yes, we recently developed and released the Twist Stop Wheel which was initially based on a request from a customer. Additionally, the Oiling Guide is another product that we have put a great emphasis on. Conventional oiling guides require that you change them every time depending on the fiber, but with this new type of oiling guide, you only need to change a single component, making it much more environmentally friendly. It also reduces the cost of maintenance. I think that these advantages are some of the elements that customers appreciate.

The company has a concrete vision towards recycling and therefore we are trying to elongate the longevity of our products. Take for example our Oiling guide. If for example the guide gets damaged, we treat the surface and revive the product for more use. The same can be said for metal-treated products which can have surface hard chrome plating treatment applied once more. These types of environmental approaches are very important within our company operations.

When we talk about the fact that we do hard chrome plating, some users don't know about it. I’ve recently come to understand the importance of reiterating what our business scope is and what products and services we can offer to our clients. Refreshing our strengths once in a while is important.

What would you say is your star product and which do you believe has the most business growth potential?

The Twist Stop Wheel has the most potential in my estimation as well as currently holding the most sales within our product lineup.

Imagine that we come back on the very last day of your presidency and have this interview all over again. What goals or dreams do you hope to achieve by the time you are ready to pass the baton onto the next generation of Yuasa Yarn Guide executives?

The value of the company is determined by the clients, so therefore we need to evaluate, increase our value, and constantly enhance our operations. We must work to receive trust and reliance from our customers. It is an act of growing together with the customers, sharing the profits, and contributing to society as a whole. This is all necessary to continue the sustainability of our company while also increasing our value as an entity.

Contributing to our society leads to our happiness as a company. Happiness leads to profits and thus the circle continues positively and energetically. Finding stability to ensure the happiness of stakeholders is a key goal of the company. Upon achieving this goal we can provide employees with a happy and prosperous life.

I hope that the next time you come here to interview me there will be peace around the world and unity among all people. I hope we can all overcome the sadness that the world is currently experiencing.

For more details, explore their website at https://yuasa-yarnguide.co.jp/en/

0 COMMENTS