Green Science Alliance is a chemical company that researches and develops cutting-edge technologies that is ensuring that the future is green for all.

Japan is dealing with a demographic change. It has one of the oldest populations in the world, and it’s declining each year. This is creating two pressures on Japanese companies: a declining market and difficulty finding staff. For the latter, it’s estimated that by 2040, Japan will have a shortage of over 10 million workers. How is your company reacting to these challenges, and to what extent do you think Japanese firms need to look overseas to solve these challenges?

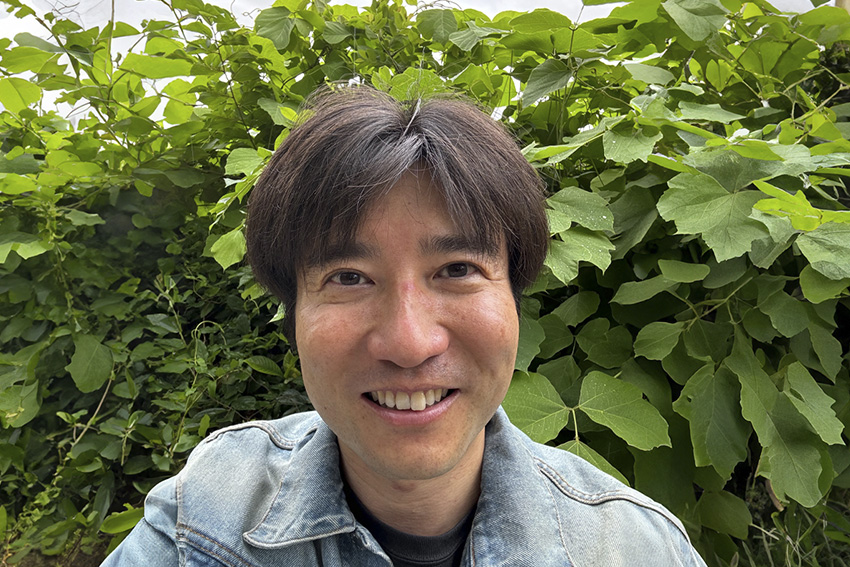

We are trying to hire people in their 20s, 30s, or early 40s. Fortunately, our business is growing, so we need more researchers. We are hiring part-time staff, which is a change from just three or four years ago, because of the population, as you said, especially for the younger generation. Things we need to do now are to offer a better salary, more days off, and better working conditions. We need to show potential employees that we are trying to do these things and that our company is a good place to work, so it is necessary for the company to adapt to the new circumstances. Even though we are a small company, we must adapt to attract excellent, younger people.

Normally, especially in this country, the bigger companies attract better candidates, so even though we try to do our best to compete with them, as you said, we have no choice but to look to other countries to find more talent. Not only me but also Japanese people, in general, have to be a little more aggressive about marketing outside of this country to find new markets and attract new talent.

My business, including our group company, Fuji Pigment, has over 100 people. It’s a small to medium-sized enterprise (SME), not a stock-listed company, so unfortunately, we don’t have a good human resources department.

You are trying to expand your operations overseas. To help you set up these bases, have you found local partners who could help take a bit of the pressure off your shoulders? And are you currently looking for any partners as well?

Currently, it’s always just me who must act. Two other people can speak English well. Still, they are also quite busy doing other things, so I always have to move around to establish things, whether it’s real estate planning, securing visas, or finding trustworthy people, so that’s my challenge.

It’s always faster to do things by myself, but in Toronto, fortunately, I found three or four Japanese people living there for over 30 years. They were promoting some kind of small agriculture business, and they became interested in our biomass chemical business, so we just recently established a joint venture company with them. In Switzerland, it’s only me. A half-public, half-private innovation research institute in Switzerland focuses on batteries, so I am now asking them to please cooperate with my company.

Japan is a very resource-poor country. It’s mountainous, with about 75% of the land covered by mountains. Despite that, we see that Japan does very well in terms of high-quality chemicals and machinery. A great example is semiconductors, where the leading players like JSR for photoresists are Japanese. Can you tell us why Japan is such a leader in these highly advanced technologies or provide insight into Japan's research and development capabilities as a nation?

Even though nowadays China, Korea, and Taiwan all have great technology and really smart people, companies like JSR, as you’ve mentioned, are sort of hidden high technology leaders. I think maybe that’s a result of the Japanese national personality or culture of wanting to chase high technology and pursue excellence. However, sometimes they add too many unnecessary things, like unnecessary functions on the smartphone.

This also affects my business. For example, if I show a plastic bag made of plants, they might say it’s weak. Of course, petroleum based plastic is always stronger than plant based one, but they are stubborn, and they often chase for too much, making things over-spec and do not start selling to the market until they are perfect. That’s why I think Japan is losing money as well.

Another example are the toilets in this country. I think it shows the nation’s personality or character. You never see such a nice, clean free public toilet anywhere else.

You mentioned the perception that petroleum-based plastics are stronger. Obviously, with climate change, there is a realization that the use of petroleum-based plastics on a wide scale is damaging the environment, but so many manufacturers and companies are reluctant to switch to a biomass alternative. There’s a perception that using bioplastics will increase costs or be difficult to adapt to existing manufacturing processes. What are some steps that need to be taken to overcome these challenges to large-scale biomass plastic adoption?

As we are a chemical manufacturer, we should focus on raw materials. For example, I gave a sample to a molding company, and they said it was good but expensive. With a petroleum plastic bottle, they can make 1,000 per day, but with our plastic, they can only make 50 per day, so they cannot use it. That’s one reason I came to the idea of doing everything ourselves, from modifying the chemicals from the raw materials to the end product. Otherwise, it might take ten years. It already took ten years, so I don’t want to take another ten years.

Going from raw materials to B2C is maybe a crazy idea, but that’s my goal. That’s why, for example, I want to make end products like nail cosmetics made from natural biomass and try to lower the price ourselves because we’re only one company. That’s the direction I’ve been working towards for over ten years.

Of course, plants are good for CO2 reduction, but not many people are willing to pay more just to reduce CO2. That’s why, at least, we’re trying to use biomass organic waste to reduce the cost. Ultimately, the government has to change the policy forcefully.

You said that you have decided to make your own products. How have you been able to develop your manufacturing capabilities, and what sort of marketing channels have you been able to open to have your products introduced to other firms?

I’m the only one being aggressive with this. My employees sometimes don’t know what their CEO is trying to do, but even so, I work with some researchers in my manufacturing factory to make the products. I read articles and write them, so I am kind of like a professor, but one that likes money, so I read and study by myself, and then I focus on one topic or category that hasn’t been done yet. We focus on that point with a few people and time to make them efficient, but as a small company, marketing is the most difficult part. Of course, if Panasonic were doing the same thing, it would easily become today’s news, but even if I develop the great products, it won’t be big news.

There are so many fascinating research areas that you’re focusing on, but if you could highlight one or two areas that you’re particularly proud of, what would they be?

Nowadays, I would say the nail cosmetics and the rechargeable battery are finally about to become real and hopefully profitable.

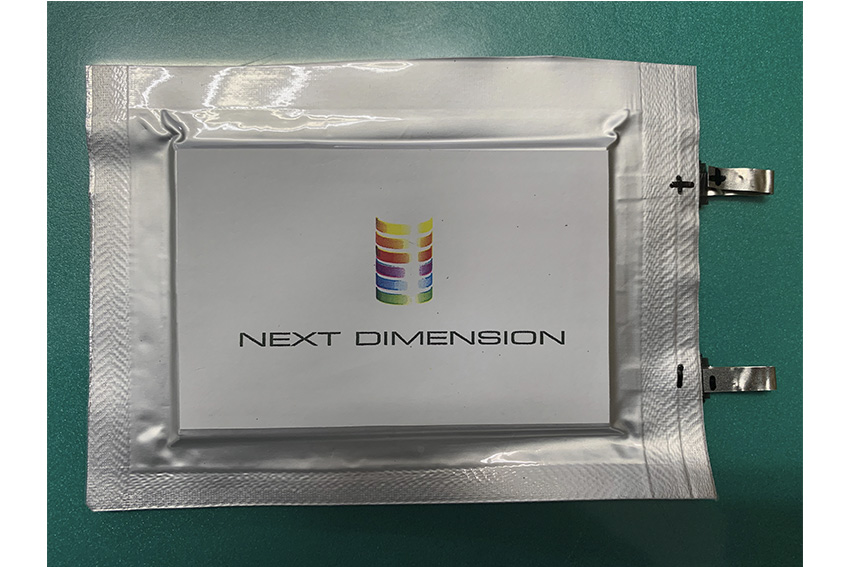

Rechargeable battery

What is the uniqueness of your rechargeable battery?

It may be the first recycled lithium-ion battery in the world. It’s complicated, but lithium-ion batteries use lithium, cobalt, nickel, and manganese, which are expensive metals, and they have to be dug out of the earth. Of course, there is a tendency to promote recycling, and the recycling companies gather the batteries, crush them, and take out the material, which they call black mass. It’s a black powder that contains those metals. At the moment, those companies use something like sulfuric acid, hydrochloric acid, or similarly strong chemicals to separate and extract the metals from the black mass powder. These are then used to make new lithium-ion batteries. This is obviously a very long, expensive, and dangerous process. In the end, the cost of making a recycled battery will be high, and that’s why it’s not practical, so I came up with an idea to make the process much simpler without using toxic chemicals. The tradeoff is that the battery power goes down about 10 to 15%, though we are trying to improve that. Even so, it’s quite usable.

This results from twenty years of my research, and it’s a bold move for batteries, but we are now making batteries in Shiga prefecture. We are also trying to do that in Europe and Switzerland, and maybe we can try in Canada with a joint venture company because batteries need to be made on each continent.

That would seem to come at an opportune time, as there are a lot of stories in the media about China controlling the mines for those metals. Companies like CATL have a huge market share for these batteries. Can this be a means of overcoming geopolitical tension?

I think so. This word, black mass, is not well known, but I think that when industry people start to think this can be connected with real money, then they won’t say anything. In fact, everybody is making black mass now, but they don’t say it. For example, some large German chemical company, started making black mass three or four years ago. Obviously, they chase profit, so they must think there is a market opportunity there, so using a battery made from black mass could be interesting. That’s why I’m pursuing patents for my technology.

What is the main industry that you see this application suiting?

There are many applications for next-generation rechargeable batteries, but since this is a lithium-ion battery, showing pretty good cyclability and durability, it could work for all lithium-ion battery markets. It could be huge, which is why I’m pursuing international patents, even though they are expensive.

Your Re:soil plant-based vegan gel nails, biodegradable vegan nail tips, nail polish, remover, nail cosmetic containers seem like quite a departure from your other activities. What made you choose the cosmetics field as an application for this technology?

I’m trying to do sustainable things in about five or six categories: rechargeable batteries, CO2 plant-based chemicals, fuel cells and solar cells, inks, and CO2 capture and conversion, which is like artificial photosynthesis. Everything is based on the purpose for CO2 reduction and plastic pollution reduction, so I’m always chasing the same goal with different materials. The common feature is that they are always materials, so I guess I enjoy synthesizing new materials in a molecular level. In everything I do, the common factor is always material engineering.

In terms of markets, you have an online store for the Re:Soil nails with the prices listed in US dollars. Do you see this nail business as being a gateway to get your company into new markets in the future?

We don’t have good sales yet, but the orders we get are always from outside of Japan. Actually, the main purpose of having the e-commerce site is to show investors and customers what can be done with our raw materials.

In a couple of months, we are going to set up some retail space on the west side of Shibuya to showcase the Re:soil, Bio-Sakura product (plant based products such as cutleries, plates, cups, bottles and paints) and furniture made by a 3D printer using our plant-based plastic. It’s mostly just to show what kinds of things we can do with our materials.

Now we cooperate with designers and academics, so after twenty years of hard work, we collaborated with them to make robust and functional furniture, like chairs and tables, for example.

My ultimate goal is to make a house with a 3D printer. There is an American university making a 3D printed house with bioplastic as an exhibition or proof of concept, but of course, they don’t need to consider profit. There are companies already 3D printing houses with concrete, but the inside is awful. Still, that is useful in an emergency, like after a bad earthquake. I am thinking of creating more comfortable real house and buildings with our plant based materials with 3D printing technology.

The Osaka Expo is coming next year. Will you be exhibiting anything there?

We may be able to exhibit our products in a small scale, but not for sure yet.

Your quantum dots material is very interesting because it uses plant waste and when manufactured, it can have some characteristics of the different plants. For example, it could be used for antibacterial purposes, to replace common disinfectants. Could you tell us more about that?

The concept or development of quantum dots actually received a Nobel Prize last year, but they still need to be successfully commercialized. There are even quantum dot television and quantum dot biomedical uses, but the business applications still need to be expanded, and since we are a small company, we are not selling them yet. Or, we sell some, but a significant amount still needs to be paid. As I was thinking about how to sell, I came up with the idea of making quantum dots from biomass, so I ended up making wood waste, paper waste and food waste quantum dots, but there’s still an open question about how to use them. Afterward, I discovered the antibacterial properties. Of course, there are many antibacterial materials already on the market, but many are petroleum-based materials or even a little toxic. For example, cosmetics use antibacterial material made from petroleum, so the cosmetics industry seems to be interested in learning more about this biomass-derived antibacterial material. I am also thinking about applying those antibacterial quantum dots to my other products. I’m also looking into the ability to use them as a pesticide for agriculture because, again, they are still mainly using petroleum-based pesticides since naturally derived pesticides are less effective.

You mentioned collaboration. How do such partnerships benefit your research, help you develop these products, and ultimately bring them to market?

Sometimes, as a small company, we have to use the university’s name to get attention. For example, this black mass-based battery is my new idea and I’m going to speak about it at an American Chemical Society conference this month, and some academics are also chasing this black mass-based battery. Some people noticed my idea and became interested. They asked me to see the material, and that led to collaborative research.

Another example is fuel cells. They use platinum, which is obviously very expensive. What I’m making is a platinum alternative material with cheaper metals. This is also research that universities are interested in, and we started seeing similar results with our material, so a university wants to explore a collaboration using our materials.

As for the pesticide I just mentioned, someone at Tohoku University noticed the uniqueness of this product, and they want to learn more about it. They have a better-analyzing machine, so it might be interesting to work together. They even have a radiation analyzer, which is going to be available next spring, I think. Since quantum dot based fertilizer and anti-microbial materials get into plants, you can see their traces in the plant. They can see it with UV radiation. They are also interested in tracking how the quantum dot traces move in the plant because that’s one of their specializations, so we are currently negotiating with them about working together.

You are incredibly busy. You are the president of the company, a lead researcher, you’re setting up collaborations and trying to sell your products as well. How do you find people or partners to help you with all of this activity?

That’s difficult. My idea always comes first, but then if things don’t move easily, I get stressed, and my staff gets a bit tired. Ironically, even as I am promoting biomass chemicals, our petroleum-based color business is growing, so I’m basically sucking up all the profits to research it. I’ve been working on this for over ten years, but ironically, biomass-based products are still not making a profit, and petroleum-based ones are.

As a small company, I write press releases in Japanese and English, and advertising is always necessary to accelerate things because now everyone is doing bioplastics, and they might catch up.

That commercializing aspect is very interesting because you’re located in Japan, which is a conservative society. People tend to stick to the older ways and do things that already work, but you’re going to Europe and North America. Where do you see the most potential for immediate commercialization?

Nail cosmetics, biomass chemicals, and recycled lithium-ion batteries have the most potential for immediate commercialization. I think it might be faster to go public to raise more capital to accelerate the research and the business, but due to some group company stock problems, it’s difficult. That’s why I made a new company, for which I’m trying to raise capital, and that’s why I’m talking to many investors now to raise money for manufacturing, sales, and further research to be independent of Fuji Pigment.

Your company is very young. You established it in 2010. If we were to return in 2030, at what stage do you imagine the company would be? What are your personal goals as president?

We should have had an IPO by then. Initially, I’m talking to investors about biochemical products and rechargeable batteries, so I want first to make a profit with those two pillars and then pursue other products like the quantum dot-based fertilizer, pesticide, platinum-free fuel cells, CO2 capture and conversion to reduce global warming, and a water harvesting device from air based on metal organic frameworks, which I think we can use in the desert. That last one is based on M.I.T. technology, but we modified it and have our own patent.

Hopefully, we will still be doing interesting—maybe a little crazy—cutting edge research with some good results, so attracting talented researchers is another important goal I have.

For more information, visit their website at: https://www.gsalliance.co.jp/

0 COMMENTS