Holding multifaceted businesses under its umbrella, Tokyo Boeki Group enhances peoples’ living by offering creative solutions such as the world’s first loading arm for LNG.

It is our view that Japan is at a very exciting time for manufacturing. On one hand, we have had major supply chain disruptions in the last three years, caused by the COVID-19 pandemic as well as tension from the China-US decoupling situation. As a result, we are seeing many multinational groups try to diversify their supply chains with a focus on reliability. This is where Japan can enter; a country known for decades of high reliability, trustworthiness, and short lead times when it comes to production. Now, with a depreciated JPY, it is our view that there’s never been a more opportune moment for Japanese manufacturers to meet the pressing needs of this macroeconomic environment. Do you agree with this premise, and why or why not?

Yes, I do agree that it may be a good opportunity, however, hearing and listening to partners that we have has revealed that there isn’t too much positive talk about the current macroeconomic situation. Speaking specifically about the export sector there has been growth thanks to the depreciated JPY, however, as you fully understand, the economy is not a simple thing. It is convoluted and complex in nature, which means you have to dig deep rather than take things on surface value. Additionally, the Japanese economy in particular is hugely dependent on imports of energy and raw materials. With the depreciation of the JPY, the costs of imports are on the rise.

Generally speaking, if a business were outside of Japan I think the situation right now would be a very favorable one given the depreciation of the JPY, however, those that operate domestically have seen the price of production rise given how imports and components are now more expensive. It has become a struggle that many Japanese firms are now facing.

In the 1990s the Japanese bubble economy burst, and during the following decades Japan experienced what was colloquially called the “Lost Decades.” During that time there hasn’t been any inflation, a rise in the price of commodities, or a rise in salaries. It is

because of this trend that it is very difficult domestically to increase the price of products.

For the first time in 20 years, the Japanese government took the lead together with the economic association to increase salaries by 3%. However, this will add costs, thus creating a burden on company expenses. It requires firms like ourselves to see the overall flow of the economy and balance out expenses.

On the other hand, the export situation is giving Japanese firms a competitive edge when it comes to international business. We are eager to actively seize these opportunities. There are downsides, and really this advantage only comes from producing inside Japan and exporting overseas, and with many Japanese firms now producing outside of Japan, the yen depreciation is giving them a different view.

You mentioned the labor force and the fact that you have to raise salaries. Japan is known to be an aging population with a shrinking demographic due to low birth rates. This is creating a labor crisis and a shrinking domestic market. Being an international group, how much do you rely on international opportunities to ensure business growth?

If you look at our company name, the word Boeki means trading, and for a while 80% of our business was international trading. However, recently the situation has changed, with 20% now for international trade and 80% for domestic business.

It might look unfortunate that we were forced to reduce the ratio of our overseas trade considerably, however, we are anticipating a great opportunity coming up so it seems like we have leeway of increasing that 20%. This in turn will increase our international business reliance.

Could you tell us about this forthcoming opportunity?

We actually have established strength in a number of domestic markets with high market shares, such as loading arms. These loading arms are used for infrastructure such as power generation facilities and liquified natural gas (LNG) stations. When the Japanese economy grew, the demand for energy went up, increasing our business. Recently however, infrastructure development in Japan has reached a saturated phase. Still, looking abroad to countries like Thailand, Indonesia, and Vietnam, there is a requirement for the construction of LNG stations and power plants. We want to start entering new markets and providing our technologies.

The Liquified Hydrogen Loading Arm that you developed is the world’s first and was a collaboration with Kawasaki Heavy Industries (KHI). Could you tell us a little bit about the challenges you face when it comes to transporting hydrogen and how you’re helping to alleviate the stresses in the system?

As for the background of the development, we as a company have been envisioning a future of a hydrogen society while the government promoted the vision, but right now it is hard to tell exactly in what form of hydrogen the society would need; it could be a liquid form, a gas form, or even an ammonium form. We were trying to get involved in one of the many options out there, and KHI contacted us to develop a loading arm dedicated to liquid hydrogen.

To realize the decarbonated society I think that hydrogen is a good option for Japan compared with other renewable options. For instance, Japan is not suited to wind power. Solar might be an option but in terms of realistic renewable sources, I think that hydrogen poses a great opportunity for the Japanese market.

The uniqueness of Japan is that it is an island nation, and if the country is unable to produce enough energy it means we have to rely on imports. KHI is now focusing on transporting hydrogen from overseas to Japan in the form of liquid because you cannot transport it as a gas. By liquefying the hydrogen you can reduce its mass by one over eight hundred. Additionally, the Japanese government is actively subsidizing multiple possible options and the KHI project is one of them, in order to promote the pursuit of a hydrogen society.

The difficulties associated with liquified hydrogen are the temperature requirements, and when transporting liquified hydrogen you have to drop the temperature all the way down to -253 degrees Celsius. LNG, which our conventional loading arm handles, liquefies around -162 degrees Celsius, meaning there is almost a 100-degree difference.

With temperatures this low, when the LNG goes through the loading arm pipes it creates a kind of condensation, however, with hydrogen being even lower in temperature you have to insulate the pipes much completely. If you didn’t insulate the pipes well oxygen would condense causing drops from the surface. Liquified oxygen can ignite other materials, even dust, on contact with oil. Thus, the biggest challenge is the creation of perfect insulation that does not cause any liquid oxygen to form on the. For insulation urethane or other materials are usually used but for this loading arm, they do not work. So we newly developed a double-layered pipe that inside has a vacuum so that heat will not transmit.

This double-layered technology is not only embedded in the pipes but all of the components of the hydrogen loading arm. I think this is a unique and cutting edge technology that our company has developed through what we have accumulated in the loading arm business.

In the automotive sector, we are seeing a once-in-a-generation change with the shift to EVs. With this shift, there are huge challenges in terms of product development as well as materials with lightweight materials like magnesium or carbon-fiber reinforced polymers (CFRP) getting preference over more heavy ferrous metals. We know that your firm has an office in Mexico, which is a hotbed for automotive components and manufacturing. Can you tell us about how you’re developing products to meet this next generation of vehicles?

We are involved in the automotive industry through the provision of our measurement systems, mainly as a system integrator, not through actual development but rather in a coordinating role. Basically, we are in charge of finding the best solutions to meet the needs of data collection and analysis for our customers.

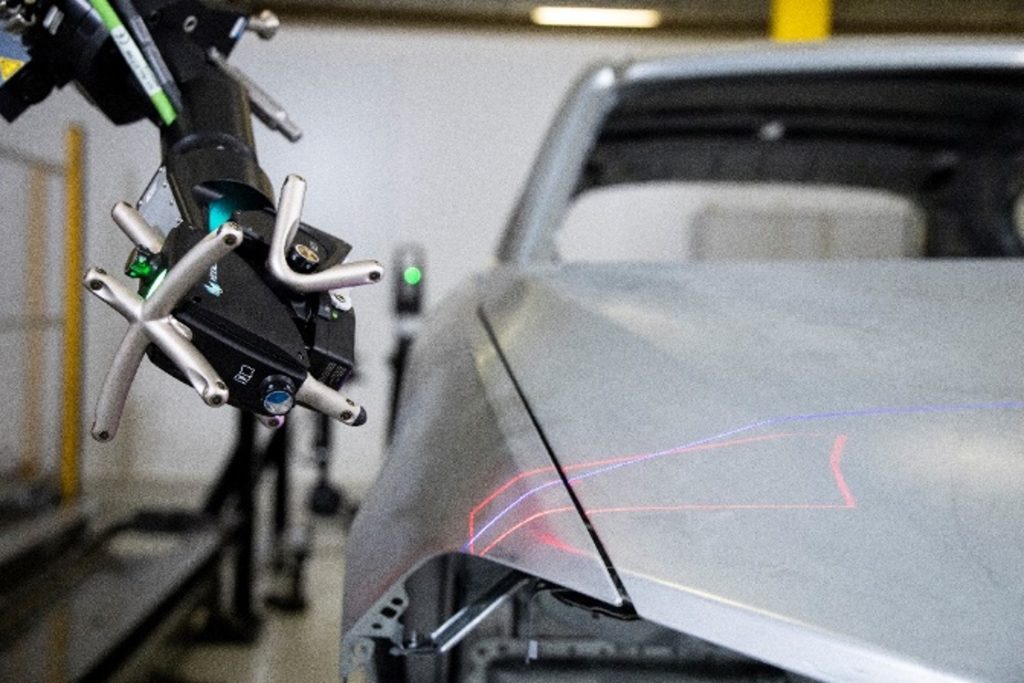

The scanning technology you mentioned we’ve seen in your Leica AT960 for example, and this product along with others allows you to scan car press panels and bodies, and other parts or objects. However, some challenges still remain, such as the time of the scanning process is long and the accuracy can suffer if a product has difficult shape or surface condition (etc. glossy surfaces) as well as the temperature in the room is challenging. Could you tell us how you ensure that your products can overcome these issues? Do you see this technology being utilized in other industries besides automotive?

In our group company we do have Tokyo Boeki Techno System, and they take care of our measurement systems. The ongoing target is to minimize the time of the measurements while also increasing the accuracy of the data collected. Specifically speaking about temperature control, I am aware that there is a special device that makes corrections and adjustments to the temperature in order to enhance the accuracy of the measurements made. They already have many Leica laser tracker customers not only in automotive but also other industries. I am confident that their 3D solutions can solve challenges in many industries.

Your group tackles a wide range of industries such as energy machinery, automotive, and medical, but right now we are in a very turbulent era that requires companies to adapt to the changing economic environment. Could you provide us with some insight into how you are developing your management axis to drive your company in all of these different industries? Out of all of the industries your group has a presence in, which do you feel has the most potential for future growth?

First of all, you might be wondering why Tokyo Boeki has such a multifaceted business approach, and I would say that is mainly because we consider ourselves a trading firm at our core.

Our company was established in 1947 by Mr. Yasuo Matsumiya. He first entered Mitsubishi Trading Firm, went to WWII and came back to Mitsubishi after the war. Then the US dissolved this giant firm and Mr. Matsumiya decided to start up his own trading firm. Since Mr. Matsumiya had a background working for a trading firm he settled into the business, and in fact, the first business he did was exporting artificial flowers from Japan to the US.

After WWII Japan struggled to rebuild the country and people had to import materials into the country. It was during this time that many manufacturers began exporting products which helped the country rebuild after the war. Trading firms during this era played a crucial role in trading raw materials and technologies, which allowed manufacturing firms to thrive. At the time we were engaged in trading as our company name shows. We were importing materials such as iron ore and exporting machinery and steel. Our current business includes the loading arm we discussed earlier as well as our liquified petroleum gas (LPG) compressor and the measurement devices we have discussed today. These businesses started when we imported from the US and other countries in Japan because these products were not really present domestically. I think the reason we are so diverse in our business is simply because of the fact that we started as a trading company and evolve into a manufacturer or a solution provider, etc. catering to customers’ needs. Our role in the economy is to fine new ideas, products and technologies and rebuild them into optimal solutions for our customers. We would like to continue this approach as the company grows into the future.

Deepening and expanding our current business areas is important to us, but opening a new business is too, so to that end we are keen to pursue further DX to enhance our business capabilities.

Imagine that on the very last day of your presidency, we came back and interviewed you again. What goals or dreams do you hope to achieve as president of Tokyo Boeki before you are ready to hand the baton onto the next generation of executives?

I think my goal is very simple; I want to make our company as good as possible. I think that a good company is really defined by their employees and the happiness those employees feel when they come to work every day. This happiness can be measured by the salaries or physical factors at work, so in order to keep those aspects as high as possible it is important that the company keeps growing and increasing profits. I think that beyond the materialistic satisfaction of our employees, there is a psychological element too, and in order to keep employee motivation high the company must continuously provide new opportunities for new business so that we can generate excitement among our staff. I would be very happy if I could make a good company.

0 COMMENTS