Founded in 2014, SoftBank Robotics Group Corp. (SBRG) has, in a short space of time, become an industry leader in the field of service robotics, a sector whose global market is expected to double between now and 2030, reaching approximately $44 billion.

|

Traditionally, monozukuri, the Japanese approach to manufacturing, has covered everything from philosophies of manufacturing to production techniques. In recent years, monozukuri culture from Japan has been defined by robotics. Japan has become a world leader in industrial robotics with a 45% of the global market share. Your company is a leading company in the field of Professional Indoor Facility Mobility Robots, can you give us your take on Japanese monozukuri, and why Japan is such a hotbed ecosystem for developing such robotics technologies?

Tracing back Japanese history, this is my understanding, but I believe Japanese industrial robots evolved together with Toyota and other manufacturers during periods of rapid economic growth. In order to manufacture, robotics and automation at factories were essential, and that's why the Japanese firms were developing these robotics. However, what we provide to the market is different from those robots, our robots are the ones which are designed for commercial use in various environments as they incorporate AI or autonomous features.

When I was younger, I took it for granted that Japanese household equipment and home appliances were the number one globally, but when I joined SoftBank and went to Las Vegas to CES (Consumer Electronics Show), I realized that Korean and Chinese products were actually overtaking the Japanese ones, and that really agitated me.

I became determined to continue pursuing robotics in Japan, which could be considered, like judo, a Japanese tradition that is embedded in our culture since I understand that robotics especially for manufacturing business has evolved with the development of the automotive manufacturing business as well as other manufacturers.

We have the SoftBank Vision Fund which does investment into new and cutting-edge technologies in our SoftBank Group. The question is how to integrate these technologies into the production of robots and spread that across the globe.

We have a very global vision, and since our headquarters is in Japan, the market which is very strict for the product quality and the quality of products is controlled from Japan we consider it as a Japanese product. The uniqueness of Japanese manufacturing is quality, so we are always consulting with the market in doing kaizen, or continual improvement.

Key features of our product development our business as Japanese robotic company are explained as below:

- There are not many companies like our company in the world that have brought so many service robots to the market since our establishment in 2014.

- We have been in the robotics business for a wide range of industries and applications and are constantly getting feedback and making improvements (Japan is very strict about quality, etc., so our experience in the market has been a plus).

- SBVF has been investing in cutting-edge robotics and AI companies around the world, and such SBVF and SBG's network has always been a plus for our business.

With your company heavily focused on the social aspect of robotics, can you give us your take on the demographic change here in Japan and how your company is facilitating that automation?

It is very true that with the aging population, Japan is actually showing an acute drop in the labor force, and because of that, many shops and businesses are closing down due to lack of human workers. Actually, we believe that Japanese society is too reliant on the human workforce, and that it could be replaced and compensated by robotics.

People also tend to regard the installation of robots as a solution to improve work efficiency, but they can also improve the level of services provided to their customers, generating a synergy between humans and robots.

Our ideal society is to create a co-existing environment with robots and humans, so we want to continue serving high quality solutions to society.

What do you think is missing for the international global adoption of robotic solutions today?

It is true that it’s very hard to buy and sell robots since the true benefits of introducing a robot has not been well recognized in society, even until now. However, many people on the management side in business are proactively wanting to introduce robots simply for efficiency. However, since people on-site have to change their operations when introducing robots, it can be burdensome to incorporate a robot.

Besides that, the impact of introducing the robot is more than just for efficiency. Robots can even improve customer and employee satisfaction as well as improving the work efficiency when it is installed in the workplace in the appropriate way. It’s very hard to show such benefits on-site with the introduction of robots to all of our targets.

If we keep waiting, society will gradually start accepting robots and we would eventually have more sales and penetration that would make it easier for robots to be sold. However, I think we should not just wait for that time to come.

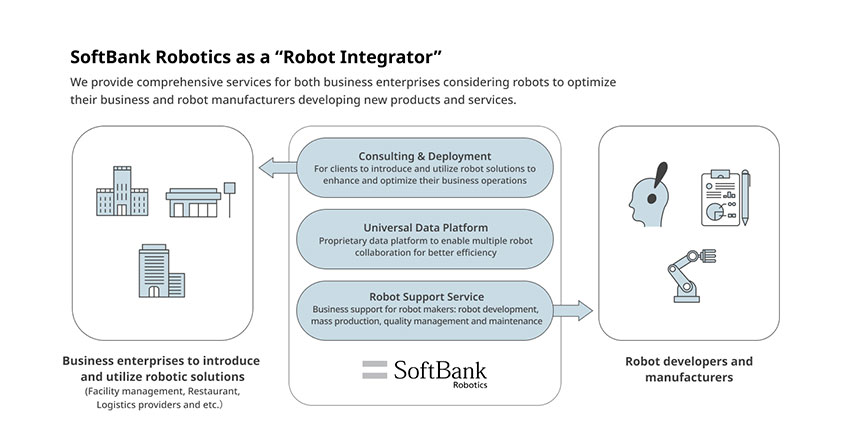

We are now a robot integrator, providing not only the robotic products itself but also consultation for the business of users who try to introduce robotic solutions. We also support the business of robot manufacturers, and even manage a proprietary data platform to facilitate optimization of the global robotics business, and we believe this will lead the market to accept the robotic transformation.

You created a partnership with a Norwegian company that creates an AutoStore, which is a type of system for high-density automated warehouses. Can you tell us a little bit more about this particular project?

AutoStore is “Cube Storage Automation" (automated three-dimensional containment) technology, which is a high-density container storage and retrieval technology for logistics. AutoStore's automated warehouse picking system, AutoStore, reduces warehouse space by 75% compared to conventional warehouses. Since aisles and shelving can be eliminated, nearly all warehouse space can be maximally utilized as container storage space.

In 2021, SoftBank Group announced that it has agreed to acquire a 40% stake in AutoStore for $2.8 billion, and SoftBank Robotics announced the contract as the first global distributor of AutoStore as a Japanese company in June, 2021 as well.

Besides that, in September 2022, we announced the launch of a logistics automation business starting from the Japanese market, that is the business to propose the optimization of logistics by utilizing our network and various AI and robot technologies from around the world related to logistics.

Our logistics automation business is based on the concept of "optimizing logistics with the world's technology" and proposes automation solutions utilizing the world's leading-edge technology including AutoStore to meet customers' issues and requirements.

Worldwide robotics have been adopted extensively by larger corporations, yet critics point out that smaller companies have not yet fully adopted robotics to the extent they were expected to. When will the point come when SMEs can adapt robotic technologies? What steps are you taking to facilitate the smaller players to join this robotics revolution?

This image of the slow adoption of robotics among SMEs will certainly change in the upcoming few years. With our company, products like AI commercial cleaning robots, such as Whiz series and Scrubber 50 Pro, and tray delivery robots, such as Servi, Keenbot T5, KeenbotT8 and Delivery X1 are already penetrating into SMEs, and this kind of robotics is something that is incorporated into their business operations and contributed to both customer and employees satisfactions as well as improving efficiency.

However, the understanding for those solutions has not been penetrated well yet, but once it gets to a certain level, it will surely boom, and have huge penetration in the market. It's like a fax converting into an email.

We see you are actively partnering with companies around the world in various industries. And you recently announced the partnership with Autonomous Solutions Inc. (ASI), an American company that does landscaping based robots. Can you tell us more about what kind of partnerships you're looking for in the future? What kind of innovation will you be focusing on, and how can open innovation help you achieve it?

When we find a partner and collaborate together, there are two criteria that we base our decision on. First is the level of the technology and if it fits with our business scheme, if it could be sustainable within our business framework, and second is if the market size that the technology can be used is big enough. We've been launching our products in the field of facility cleaning, tray delivery, humanoid and recently launched the business in the area of logistics automation. Where next would be based on these two criteria, finding the right market size and finding the right technology that could be turned into a business.***************

Based on our experience in the robotic business since 2014, what people expect from service robots can be divided into features brought from robots’ components like feet, eyes and hands. Actually, hands are the area that is most lagging behind, and that needs to be improved, especially finger movements. Talking about the feet or the legs, the technology is already sophisticated enough that a robot can transport itself smoothly. Eyes have also been improved so that robots can identify objects, and make sure that it won’t crash into them. CPUs need to be improved also. Depending on what kind of component is becoming advanced, we will find the right market for that.

I believe that technological advancement for all the features of robots is a matter of time. Once all the relevant technology has reached the required standard, then I’m sure that robots will take over much of the work that humans currently do and humans will assume the role of operations for such robots.

We saw that you recently released your midterm vision for the future. Could you quickly run us through it? What are some of the key objectives that you will be looking to achieve within the coming years?

The global market for service robots was 20.3 million USD (up 20% from the previous year), and is expected to more than double by 2030, reaching 42.7 million USD As society faces a variety of challenges and changes, the robotics industry needs to evolve beyond simply "making robots” to a new era of "being able to choose from a wide range of robots, mix and match robots for more customized solutions, enabling us to get the most out of their power for our future.”

As the pioneer in the industry of service robots, we have been developing our business as a "Robot Integrator (RI)" providing comprehensive services for both businesses considering robots to optimize their business and robotics manufacturers developing new products and services. We will lead this next phase of robotics with our knowledge accumulated through many trials and errors as an industry pioneer, a vast amount of robot operation data, and our wide global network as a member of the SoftBank Group.

Our core services as a “Robot Integrator (RI)”

1. Consulting services for users to introduce robotic solutions to enhance and optimize their business operations with digital transformation

2. Business support for robot makers: robot development, mass production, quality management and maintenance support

3. A proprietary data platform to facilitate optimization of the global robotics business.

Robot Integrator Strategy

Let's say tomorrow a company comes and wants to create a robot for paintings or for something that you are not familiar with. How do you ensure that you have the technical expertise and what role would you play exactly in that development project?

A recent example is a company that developed a robot that works behind convenience stores and puts drinks into display cases automatically in places like Family Mart. They can develop the robot, but they don't know how to mass produce it, so they consulted us, and we discussed how to make the structure more simplified and gave them ideas on where to do the mass production.

SoftBank Robotics Group operates a diverse group network of both regional affiliates and firms such as SmartBX who provide solutions for cleaning DX. Can you tell us about the synergies you are able to create amongst the group?

The synergistic effect we get is that we have a tight knit relationship. For example, if there's a project where SmartBX has a strength, we incorporate their members, , we have the same personnel working for SoftBank Robotics and SmartBX, so we share up-to-date information constantly.

As stated in the robot integrator strategy announced on October 18, we not only introduce robots, but also make various proposals in terms of operation and maintenance for cleaning facilities and DX in restaurants, and support commercialization of robots by venture companies that manufacture them. The company also supports robot manufacturing venture companies in their product development.

SmartBX proposes total DX solutions for facility cleaning to customers in Japan, and IRIS Robotics, a joint venture with IRIS Oyama, supports robot operation and maintenance by utilizing IRIS's network and knowledge in Japan. We will expand similar type of business like SmartBX or IRIS Robotics worldwide utilizing the experiences in Japanese market as a robot integrator.

Japan is famous for its level of spending on R&D. Up to 3% of annual GDP goes towards this endeavor. Moving forward, where will your R&D focus be in terms of product development?

We are putting emphasis on research and development, especially in the field of AI and the areas I have touched upon. I cannot go into detail, but we are working towards future creations.

You’ve a very diverse array of offices from San Francisco to Boston to Shanghai to London. Can you tell us which regions or countries you will be focusing on for future growth? Where do you see the most potential?

The introduction of service robots is progressing in many countries around the world, and we consider all markets in which we do business to be focus areas.

Among these, in China, the U.S. and Europe, where a variety of robot development ventures are being born, DX is progressing in the business areas we are focusing on, including food services and cleaning. In these and other markets, there are cases where the knowledge of the Japanese market, which demands high product and service levels, can be utilized in other countries.

Please imagine that we come back, let's say in 10 years, to have an interview with you again. Is there a goal or objective that you would like to achieve over the next decade?

Over 100 years ago, the Wright brothers flew in the sky, but now we are traveling to space. 10 years can make a massive change. I believe that compared to the last 10 years, the next 10 years will see exponential changes in the robotics field. I have something definite in my mind, but if I disclose that, it would be disclosing the company’s strategies so please forgive me.

0 COMMENTS