Shinhokoku Material, a leading Japanese manufacturer specializing in high-precision alloys, shares insights on navigating global challenges, innovating in the semiconductor industry, and fostering technical expertise amidst Japan's demographic shifts.

It is our view that Japan is at a very exciting time for manufacturing. On one hand, we have had major supply chain disruptions in the last three years, caused by the COVID-19 pandemic as well as tension from the China-US decoupling situation. As a result, we are seeing many multinational groups try to diversify their supply chains with a focus on reliability. This is where Japan can enter; a country known for decades of high reliability, trustworthiness, and short lead times when it comes to production. Now, with a depreciated JPY, it is our view that there’s never been a more opportune moment for Japanese manufacturers to meet the pressing needs of this macroeconomic environment. Do you agree with this premise, and why or why not? What do you think are the advantages of Japanese firms in this current economic environment?

Objectively speaking, what you said was very correct, and the way the world has unfolded over the past few years has meant that there are plentiful disruptions within supply chains. Additionally, with the depreciation of the JPY, Japanese companies have been put in an advantageous position for export. However, in terms of our company, we don’t strictly export much of our products. Domestically speaking, the industry that we cater to is also limited. In regards to profits, 70% of our income comes from low-thermal-expansion-alloys for the semiconductor-related industry. What is important for our company right now is to grow our overall presence throughout both domestic and overseas markets so that we can increase our market share both within and outside of Japan.

The semiconductor field has emerged over recent years, a clear direction for us to enlarge our share. Unfortunately, however, as you might be aware, Japan has been thought to lose drastically in the field of semiconductors, so working together with key semiconductor-related manufacturers overseas will become vitally important for us. There is, however, a problem for us that the semiconductor-related manufacturers overseas already have well-established supply chains, meaning it will be a challenge to enter an existing one. Our approach will be to monitor the semiconductor industry, in particular, the semiconductor manufacturing equipment companies as they are launching or developing new products and offer our products and solutions to them that address specific issues they are experiencing in terms of material usage. Our target at this point is now to become an R&D-oriented company that can contribute to the development of such semiconductor manufacturing equipment companies. For the past ten years, we have stressed the importance of development. Currently, we have about 100 employees, 10 of which are researchers and 5 of them are doctors. We are active in pursuing leads within academic fields and circles by writing academic thesis papers and presenting at conferences such as SPIE Conferences (International Society for Optics and Photonics). These types of academic and developmental activities have recently accumulated, and thanks to that, we can show a more increasing presence both domestically and overseas.

However, we do have values and try not to enter into price competitions. We need to project these unique values that we, as a company, can only provide. Overseas companies often require a standardized product, but we believe our mission is not just to provide a standardized product. Even if it's a standard product, we aim to provide the best items that have superior performance and cannot be made by anyone else, even going as far as customizing the products to pinpoint a solution to the client’s needs. This approach is something that we would like to convey to overseas companies and change the mindset in both ways.

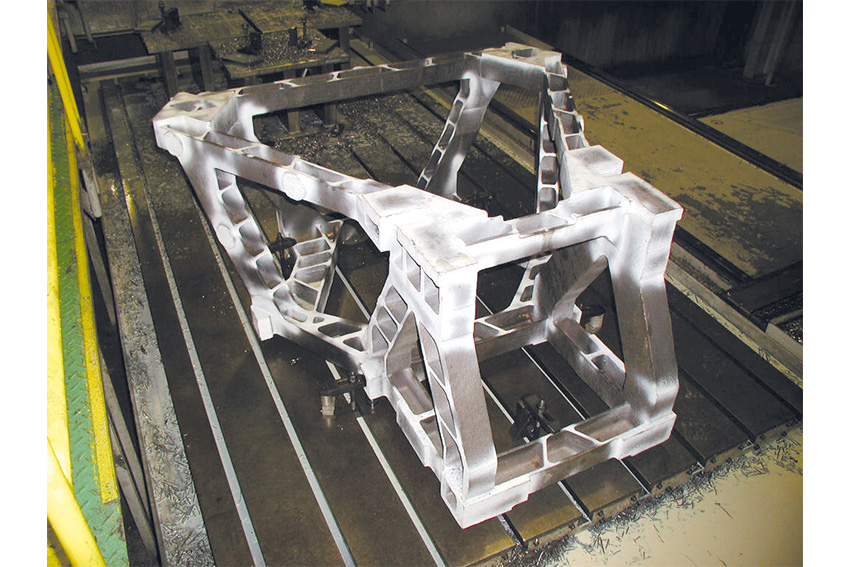

An example of low-thermal-expansion cast alloy

You mentioned that you want to expand your overseas network. Are there any specific countries or regions that you would like to cater your products to? What strategies would you like to employ to do so?

We do have a limited company size and a small number of staff to go with that. With that in mind, we do want to keep our expansion within our capacity and not overgrow. My job as president and my management style are all centered around keeping my employees happy and fulfilled with their work, not just expanding sales. What is important is to stay within our abilities for overseas expansion. Having said that, we are open to any M&A or other opportunities that are positive for us. We don’t have a direct office overseas at this point, so instead we take advantage of opportunities such as international conferences to make contact with key persons in overseas manufacturers, and we continue to steadily promote our company and our technology through technical presentations. We plan to leverage the network we have built up so far and visit several overseas manufacturers and institutes this year to lead to more concrete collaborations. So we see this right now as our method of choice in terms of continued overseas expansion.

You mentioned how a key industry for your growth is the semiconductor industry. With that in mind, which market or geographic region do you believe has the most potential for the future growth of your firm?

For overseas and domestic expansion, our current focus is on the semiconductor industry, in particular, semiconductor manufacturing equipment. In terms of what we provide, we are unique and a one-and-only solution provider for the industry. For this reason, we want to strengthen our uniqueness and work together as a tier-2 provider with tier-1 manufacturers overseas. This will allow us to continue to progress both domestically and overseas in countries where there is a need for semiconductors. In addition, since we have proprietary low thermal expansion alloys for CFRP press molding, in demand for aircraft and flying cars, we are also monitoring trends and staying in touch with the aircraft and heavy industry manufacturers.

The semiconductor industry is known for its precision and control on a nano-level. The use of specialized materials like low-thermal-expansion-metal plays a vital role in achieving these standards. Now Shinhokoku Material is no exception when manufacturing such specialized material. How do you ensure your products meet the precision level required by the semiconductor industry?

The biggest strength that we have is that we can control precisely the target chemical composition of the alloy. Specifically, we have established a technology that measures the absolute values of components by chemical titration and manufactures them exactly to the optimal target composition within a very narrow range. Chemical titration is a technique that has been lost in most parts of the world today, having been replaced by recent instrumental analysis.

Another strength that we have is the accuracy of thermal expansion measurement. We have five units that can measure down to one-tenth of the conventional measurement, which is 0.01 ppm/K. Thanks to that, we are able to go down to a minute level within a specific smaller range.

Thermal expansion measurement equipment

Your company is an R&D-oriented company, and this requires a lot of technological know-how from your staff. Now, when we look at Japan as a country, it is currently facing a population crisis. Japan is known as the world’s oldest society, and to make matters worse it has a shrinking demographic due to low birth rates. This is creating a few issues including a shrinking labor force and a smaller domestic market to sell products to. How are you tackling the issue of technical inheritance? How can you ensure that in the long term, you are able to pass on these technologies and know-how to your younger generation of employees?

The aging population is, in fact, a social issue; however, if you change your perspective, the labor shortage isn’t going to happen on an immediate basis. The reason why this social issue is considered a major problem is that the retirement age in Japan is currently 60 years old. In our case, we don’t have any fixed retirement age, and as long an employee is happy and physically capable, we allow them to continue with us as long as they want. We value aging as part of the experience-accumulating process. Many of our executives have accumulated great success for major companies throughout their careers, and I feel this is important to replicate that success here at Shinhokoku Material. This is a positive influence, and sharing experiences has a positive impact on our entire staff. In fact, we still have active staff above the age of 70, and we feel one of our company’s strengths is that we can rely on that experience to grow our company.

Having said this, it is still important to hire young people, and I think a uniqueness of our company is the fact that we provide opportunities for engineers and researchers to study at universities and obtain their doctoral degrees at the company's expense while working for us. It is very effective for us to develop new materials because we can do so by learning the theory and the guiding principles in the academic field and by practicing them in the company at the same time. Two of our employees have actually received their doctoral degrees from Muroran Institute of Technology and Tokyo Institute of Technology while working. These types of new opportunity provisions are something that we need to stress to the outside world so that we can attract more young people.

At the same time, women are now becoming an indispensable human resource in society. The industry of casting, which we are in, has traditionally had fewer women in the field of research and development, but we would like to proactively promote the hiring of more women in this field, especially when compared to more major companies in the industry. These positive elements of our company are things we want to continue to promote to the outside world to sustain our recruitment schemes.

Another means of acquiring personnel is through internships with universities, something we do accept regularly. We are also asked to give lectures on manufacturing by several universities, so we send sometimes young researchers as well as experts to give a lecture which makes materials feel more familiar to students. I wish to spark passion in the joys of new material development, with the hope that we can influence and encourage the younger generation to talk more about new material development.

30kg vacuum induction furnace for R&D melting

One of the benefits you have with doctors here at this company is your ability to not only develop new technologies but also develop your own new products. You recently launched a new product, the Super Corrosion Resistance EGNIS. Could you tell us why you decided to focus your development efforts on this new Super Corrosion Resistance EGNIS and what applications it has? Are there any other new products or developments that you would like to showcase for us today?

Although our major products are low thermal expansion alloys for semiconductor-related industries, we are also focusing on the field of heat-resistant alloys. The purpose of developing this new EGNIS was to provide environmentally friendly solutions from an SDGs point of view, particularly for garbage incinerators and biomass generation. The uniqueness of our EGNIS is that it has a high concentration of silicon that can survive corrosion and wear in severe environments.

There are over 500 waste incinerators in Japan, operated by municipalities, and their environments vary greatly depending on the type of waste burned and operating conditions. We investigate the materials' performance in each furnace with the aid of furnace operators and develop and provide the appropriate type of material that could withstand the corrosion of their specific uses.

EGNIS was developed by one of our engineers who entered the company only five years ago. This means that development was completed within just those five years. I think there is a huge energy blast of passion created by the combination of the young generation and the experience and expertise of the more established generation. This synergistic approach in our company has resulted in the creation of new types of materials that may not be obtained in other major companies. We proudly boast here at Shinhokoku Material that we are able to provide training as well as realization schemes. Right now, our R&D is focused on the development of innovative low thermal expansion alloys that have never been seen before.

Currently, our R&D is focused on developing a new type of low thermal expansion alloys that could replace glass-ceramics such as Zerodur®. Glass and ceramics are known for having zero or very low thermal expansion capabilities, and while it is used in optical equipment, they are vulnerable to breakage. We are trying to create an ultimate zero-thermal expansion alloy that could be a rigid alternative to ceramics and glass.

Imagine that we come back in six years and have this interview all over again to help your firm celebrate its 80th anniversary. What are your goals or dreams that you hope to achieve by the time we come back for that new interview?

The purpose of each company differs based on a number of factors including the size of the firm and the business it is involved in. For our company, we feel the purpose of our company’s existence is to invoke the happiness of our employees. The company is just a mere tool to bring our employees together and make them collectively happy working on mutual contributions. Recently we developed a mid-term plan to increase the happiness in our company through both economic terms and also work satisfaction. Fortifying both is crucial in order to increase the overall profitability of our company, which in turn comes back to benefit employees by increasing their finances.

Currently, our company is doing very well but we should be careful not to stagnate. Instead, we should strive to continue to grow by investing continuously in new developments, equipment, and facility developments. What is important is the discussions with our employees to create an ideal company where we all work together in unison. The recent mid-term plan was actually devised through the discussions we’ve had with employees. To make this process easier we have developed three teams: The future product development team, the production process innovation team, and the company attractiveness enhancement team. Through the activities of these three teams, I can see how engaged and how passionate our employees are.

To be very honest, our company was on the brink of extinction after the Lehman Shock, so in order to survive, we had to restructure our company. We had a casting factory here. Since then, we have centralized and cut our personnel from 200 to 100. It was a very painful age we had to go through. We are now fortunate to experience the recovery from the Lehman Shock.

In five years, I will be in my eighties. Speaking of the company’s business, we are currently providing casting and forging materials mainly to the semiconductor-related industries. In the upcoming five years, we would like to be recognized as a manufacturer of an additive manufactured low thermal expansion alloys and other heat-resistant materials. It means that we will be growing with casting, forging, and 3D printing as its three pillars.

Additive manufacturing is a new field, and we have high expectations. Currently, we have a related company that does manufacturing through 3D printing additive processes. They currently have 5 units installed and next spring we are going to install newly developed machines to our own factory. Those units will be able to manufacture the products above 1 meter in size. The hope is to have this new machine as the most attractive and valuable among the three pillars of our company moving forward.

0 COMMENTS