Always seeking the next breakthrough, Satake has over a century of experience that enables it to continually innovate in food processing systems for worldwide needs. We sit down with President Kazuhisa Matsumoto to discuss topics such as world food shortages, the global population explosion and their concept facility, a new rice milling plant, MILSTA.

Over the last 30 years, Japanese companies have been pushed out of mass market segments but have remained niche leaders in certain B2B fields, like your company in the food processing industry. Can you explain what the advantages are of monozukuri, Japan’s unique philosophy of craftsmanship?

“Monozukuri” is often understood as the Japanese “art, science and craft of making things.” It encompasses Japanese manufacturing philosophies including continual improvement, excellency, and apprenticeship.

Japanese companies can still compete in the market because they have accumulated experience and they are able to flexibly adapt to modern needs. They collaborate with not only domestic but overseas companies, as well as academic and research institutes, and work together to innovate existing technologies and create huge new demand.

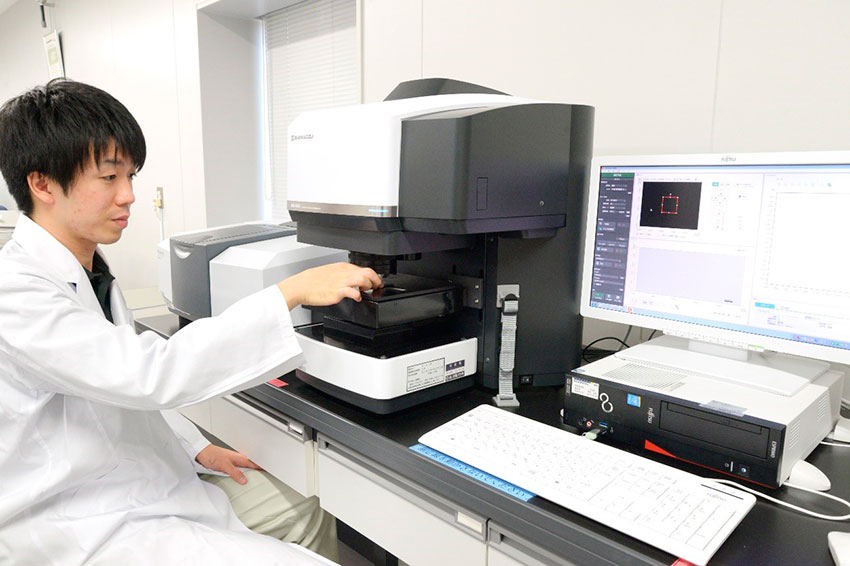

Statake grain analysis center

Some say that Japanese monozukuri is in jeopardy because of the population change which is occurring here. More than 28% of people in Japan are already over 65. With a fertility rate of only 1.37, Japan is expected to have a population less than 100 million by 2060. Now this is creating two effects. First, there are less consumers here in Japan to sell products to, and second, it's harder to recruit talented staff. Companies are increasingly turning to automated technology to replace basic labor tasks. In the case of your company, what has been the impact of these population changes? What challenges and what opportunities are they presenting?

The declining Japanese market is a grave issue for us, particularly the shrinking of the agricultural industry where we provide our machinery to private and public agricultural entities.

In order to mitigate this issue, we are working on something called the Toyosaka Project, which is trying to sustain an aging farming community. We are working hand in hand with localities where the population is becoming scarce and the aging population is becoming an issue.

In rural countryside areas of Hiroshima prefecture, we have established an agricultural cooperation to work together with local farmers to cater to their needs. We have also established a means to process their products and process rice to higher value GABA rice, for example. We’ve also opened several restaurants to promote the processed products. By combining the effects of all the aspects, first, second, and third industry, we hope the town will be able to sustain its fundamental industry, agriculture, and become a role model for other depopulating towns in the country.

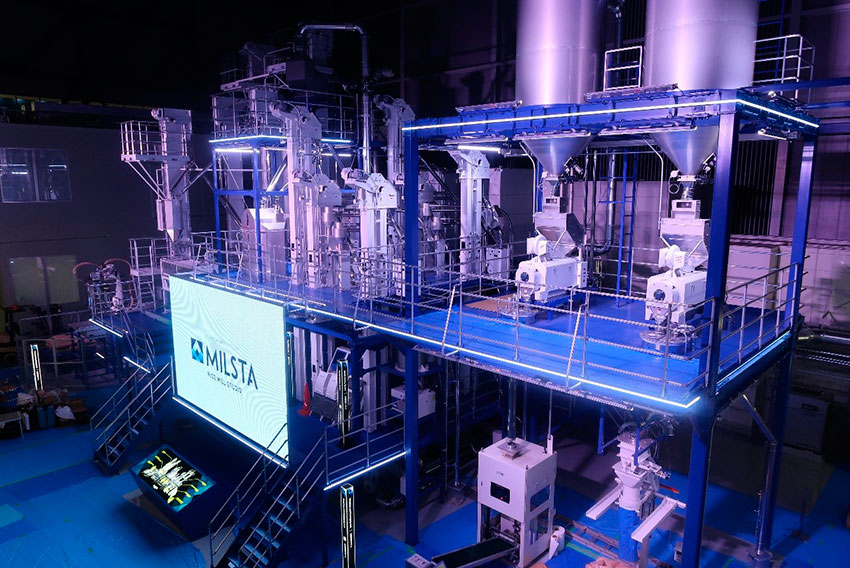

With regard to supplementing the decline in the agricultural work force, we have created a concept facility, a new rice milling plant, MILSTA, which has its main focus on automation and quality. This is to overcome the shortage of manpower as well as the passing down of knowledge which is becoming difficult these days. The fully automated MILSTA, utilizing digital technologies to save labor and improve quality, is one of the solutions we provide.

New rice milling plant MILSTA

Domestically, we currently sell about 20,000 units of machinery per year, including grain dryers, rice milling machines, and huskers. These machines require maintenance, so 10 years ago we established a maintenance company which takes care of providing maintenance for our machines throughout Japan. Five years ago, we also established a centralized customer support center in Japan to provide integrated total maintenance 24/7.

We also have very strong maintenance service programs overseas, but we want to fortify them as well. With further digitalization, we will be able to provide services faster even from a distance like that of Japan.

From a more global perspective, the global population is increasing at an alarming rate. The UN predicts there will be 10 billion people in the world within the next decade, which creates a very big challenge for the food production sector. Experts predict that we need to either double food production within the next century to feed everyone, or that we need to find a way to better utilize the food that we already produce, either through better distribution or better storage. What are some of the technologies that your company has developed in order to increase the shelf life or the storage capacity of the food products that you deal with?

As a countermeasure to the issues of a growing global population and shortage of food, we are providing and developing new technologies. Particularly in the areas of Asia and Africa, there will be a population boom and the shortage of food will be a major issue there, so these areas will certainly be the focus of our business.

We provide machinery and equipment for rice processing, drying and paddy husking, as well as the sorting and milling of rice and its storage. We have developed a new technology called the ‘long life rice process’ which extends the shelf life of rice. By employing this process before the milling stage, we are able to lengthen the shelf life of edible rice. We also have extensive experience in developing and establishing rice silos and country elevators across Japan, and we would like to take this technology overseas.

These food shortages you’ve mentioned have been compounded by recent macroeconomic crises. The war in Ukraine is putting a lot of fear in international actors over the supply of food, as both Ukraine and Russia are exporters of basic agriculture. This is happening against the backdrop of the Covid-19 pandemic, where we've seen significant logistical disruptions. How are these major challenges affecting your business?

The impact of the Ukraine-Russia dispute is that our country is not able to procure adequate energy supplies, including oil and natural gas. Because of this, the price of our products will need to be increased in the near future or we will lose profits, so the impact will be felt soon.

The area under dispute is where most grain cultivation is located, and Japan imports a considerable amount of flour from these areas, so there will be a decline of investment in Japanese flour milling factories.

However, whilst we may see a decline in the flour market, there may be an increase in the rice market. Our clients working in the rice industry may increase their profits by making up for the market’s shortage of flour, so we may be able to increase our rice related business.

Regarding the Chinese lockdown and the logistical disruptions due to COVID, we have a factory in Suzhou with 300 people and we are still able to operate our factory, so that’s good, but we're not able to fully prepare the electrical parts and components they require in order to build our machinery. We are therefore trying to diversify our procurement process and shift it more globally.

Optical sorting technology is synonymous with your company. In the US you have the Vision Systems Operation Group who use monochromatic, bio-chromatic, invisible, and visible wavelength lights to detect different types of food stuffs and discard those ones that are not viable. Can you tell us more about these technologies and how they allow for the sorting of viable from unviable food during processing?

Our technology basically focuses on the three staples that are rice, wheat, and corn. But of course there’s much more than just those three, including for example soybeans, coffee beans, sesame, and almonds in the US especially. So our products not only focus on grains, but can also be used to sort plastics or glass, or processed foods like pasta. We recently developed the Beltuza Spectra to use X-rays in response to demand from the industry that required the ability to sort things by detecting qualities of internal defects.

Optical Sorter Beltuza Spectra

Our sorting systems began with rice sorting but have evolved and become applicable to many other things. We have the Sorting and Processing Integrated Center at the Hiroshima head office to help our customers find sorting and processing solutions. Upon receipt of product samples, we use our latest technologies and accumulated know-how to meet their expectations.

Satake currently has 125 years of history with post-harvest processing. After harvesting, the product often goes through drying, husking, milling, sorting, and storing. In five to ten years’ time, all these processes are expected to be automated to mitigate the shortage of agricultural workers and operators. Our equipment closely monitors the status of the product with special sensors that can determine the moisture contents, whiteness, and all other aspects in each step so that we always have full control of the product. We call this our new digital transformation (DX) project.

Currently the equipment used in disparate steps of the processing are separate, but in the near future maybe driers and huskers will be combined as one and the process will be fully automated.

Although we have a history in post-harvesting, our research and development focus currently expands to pre-harvesting in order to fully optimize productivity and efficiency as well as maximize product quality. Providing such information to farmers is crucial to efficiently grow quality crops and have a continuous process from planting, processing, all the way through to storing to ensure maximum quality and yield and contribute to solving food issues globally.

Research and development is a huge part of your business. Satake holds more than 2200 patents and has more than 300 engineers working on projects. You've collaborated closely with farmers throughout your history and in 2005 launched the Crystal Laboratory where you showcase your technology and co-create with clients. Can you tell us more about how your collaboration works and what type of partners you're looking for to expand your R&D capabilities?

I cannot disclose much of the information, but we are actively collaborating and seeking new partners for new projects and the development of new technologies. Currently we are working closely with academic and research institutes as well as private companies within the industry and also in other industries.

It's more like coexisting together. Times have changed and it's not about competing to be the best alone, but working together with other companies, and using each other’s experience in a very good way to create a win-win situation so we can develop together and expedite the development process. You mentioned research and development, but it's not only about R&D. We’re also looking for suitable partners in the areas of food processing technology and sales.

Your business is very diversified. You're present in more than nine countries. You export to more than 150 countries such as America, the UK, and Australia. Which markets in the future do you envision your company growing into?

We are very much focused on fortifying our Asian market as well as starting up in Africa. Besides Japan, we currently have offices and manufacturing in North America, South America, Europe, Australia, Thailand, Brazil, and China. We have a strong agent in Taiwan and many others in the region, and in Thailand we're using the country as a hub to enlarge and penetrate into the ASEAN region and India. Africa is a huge potential market for rice and grain, and we have established a branch office from our UK subsidiary to cover especially the Western region.

Let's say we came back to interview you again on the last day of your presidency. What would you like to be able to tell us about your goals and dreams for the company by that time, and what would you like to have achieved by then?

I’m not the company owner but I was an employee here and became the president, and what’s important for the company is to provide satisfaction to our employees. It’s important for our employees to have an enjoyable time at work. By providing motivation and increases in salaries I want to make the work five or ten times more enjoyable for our employees. With that positive energy I’m sure that we’ll be able to continuously grow. Maybe that's the Japanese way of thinking.

At the same time, it's important to have a stable and sustainable business, and a stable relationship with both customers as well as suppliers. That’s also what I’ll continue to focus on. Together, we’ll develop our R&D capability so that we can continuously provide the latest technologies and highest service available for the changing needs of our clients.

As company president, my vision is to apply the Roppo-yoshi philosophy which means “providing goodness to 6 sides.” Traditionally there's also a saying “Sanpo-yoshi,” derived from the merchants of the old Omi province: “providing satisfaction to the seller as well as the customer and society as a whole.”

Important also is to adapt our business operations so that our suppliers and sub-contractors support the UN Sustainable Development Goals so as to ensure the next generation can also benefit from the goodness of a healthy environment.

0 COMMENTS