Hideyuki Kobayashi, Vice President of Sanden Corporation, discusses the challenges and opportunities faced by Japanese manufacturing amidst global changes. Kobayashi highlights the role of Japanese firms in diversifying suppliers, leveraging technology, and adapting to market demands. Addressing the aging population and labor challenges, Sanden emphasizes value-added production and knowledge transfer. The conversation delves into Sanden's transformation in the EV era, showcasing their expertise in tailored compressors and integrated thermal management systems for electric vehicles. Additionally, Kobayashi underscores Sanden's commitment to environmental sustainability through the development of CO2 compressors. The interview also sheds light on Sanden's strategic partnerships, global expansion plans, and future goals as a full-solution supplier in the manufacturing industry.

It is a pivotal time for Japanese manufacturing. The past three years have seen large supply chain disruptions due to COVID as well as the US-China decoupling situation, and as a result, corporate groups are looking to diversify their suppliers for reliability reasons. Known for their reliability as well as their advanced technology, Japanese firms are in an interesting position. Combined with a weak JPY, many observers argue this is a unique opportunity. Do you agree with this sentiment, and what are the advantages of Japanese firms in this current macro environment?

You are right, it is a very exciting time for Japanese companies. The core strength that Japanese companies boast is on-time delivery. Precise and accurate delivery is something that defines Japanese companies and that is also helped by the highest quality that Japanese companies can provide. From my perspective, until the year 2000, Japanese companies were focused on mass production, but that period marked a big turning point. Globally speaking, Japanese companies are now expected to be more flexible in production. I feel in this regard the quality is giving Japanese companies an advantage on an international level.

The depreciation of the JPY is contributing to exports however that is an external factor and we do not want to get carried away by external factors. Rather we would like to keep focusing on the three main aspects of our business, quality, being global, and the environment. That quality is represented by the Deming Award that we received, which is a quality assurance award. Our company is always seeking to pursue the highest, most reliable quality for our products. And with the recent events, we feel that this is a good opportunity to redefine and reinvent ourselves in the global market.

Japan is the world's oldest society with a rapidly shrinking population and this presents many issues including a labor crisis and a shrinking domestic market. What have been some of the challenges that this demographic shift has presented to your company and how are you reacting?

As for the population crisis Japan is facing, I believe this is a great opportunity for Japanese companies to make a new shift since it is clear that Japan is at the forefront of an aging and declining population. We are being closely followed by Korea, China, and Italy, so as a leading Japanese companies can propose a new scheme.

Our company was focused on mass production until around the year 2000 but now there has been a shift and we are now more focused on creating value-added products in high-mix-low-volume quantities with a bit of individuality. One of the strengths we have is that we are not in the Keiretsu(affiliated) company so that means we are able to serve a wide range of customers. As for productivity, it is most important to enhance our productivity within this high-mix-low-volume production by having minimum people necessary on-site for production. I mentioned that the strength of our products is quality, and that it has been created by the experienced engineers and processes we have. Sanden is actually one of the earliest companies in Japan to have a reemployment system for retired engineers and we highly value those veterans who have accumulated knowledge and encourage them to make further contributions to the company. We expect the younger generation to take the initiative in creation, while the importance and improvement of quality is largely passed on from the veterans. We ask these veterans to educate not only our Japanese staff but also overseas staff since 90% of our market is overseas and we also have production facilities overseas centering around our mother factory in Japan.

As the vice president of Sanden, I am dedicated to countermeasures relating to this population crisis, which is reflected in the monozukuri that Sanden is engaged in. We want to show examples and be a role model for countries that soon will be facing similar issues.

The shift to EVs is a once-in-a-lifetime change, and with that change comes new specifications. One of those includes having tailored compressors. What are some of the opportunities this switch to EVs is presenting your firm and how do you plan to take advantage of those opportunities?

The change to EVs is posing a great opportunity for our company. Traditionally we have been defined as a common component manufacturer but with the advent of EVs, we can now recreate ourselves as a total system supplier. Since there is no engine anymore, we can no longer utilize the heat emitted by the engine, and since there is no longer a heat source for the car interior heating, what we now have to use is the battery. Electricity is used to create the necessary heat thus decreasing the amount of remaining power in the battery for driving. By developing integrated thermal management systems, we can provide a holistic solution to customers who are experiencing issues with vehicle range and air conditioning inside automotives as a system supplier.

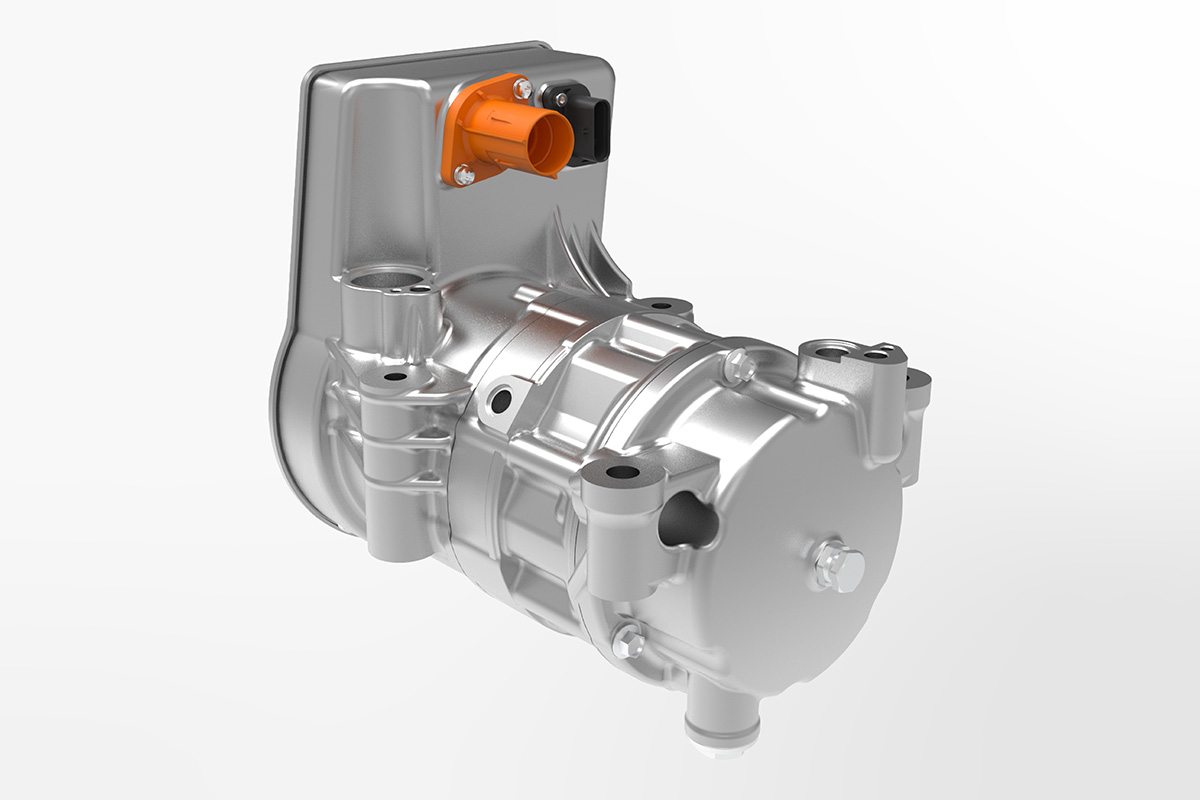

In EVs, scroll-type compressors are used as the mainstream. A scroll compressor compresses and pressurizes gaseous refrigerant by connecting two scrolls. Often, one of the scrolls is fixed, while the other orbits eccentrically without rotating, thereby trapping and compressing pockets of fluid between the scrolls. In 1981, Sanden became the world’s first company to succeed in the mass production of scroll-type compressors. With the advent of EVs, our core technology can now be widely applied.

Electric Compressor

Can you introduce us to your internal integrated thermal management system and explain how it can effectively increase the operability of batteries? How do you plan on developing this technology further?

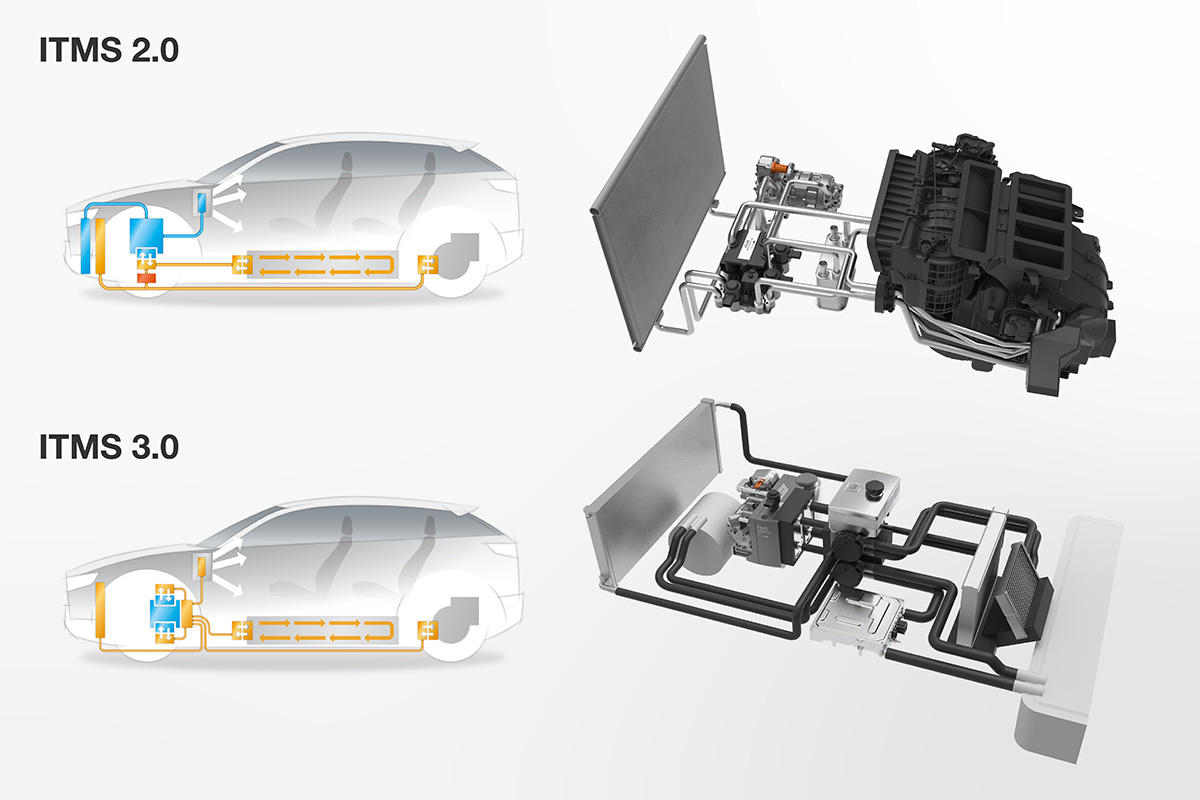

We have two types of integrated thermal management systems (ITMS), with versions 2.0 and 3.0. ITMS 2.0 is technology based on heat pumps that use various refrigerant gases. Gas is transported around in order to exchange heat. The uniqueness of ITMS 3.0 is that it uses water as the coolant and has the advantage of the size is considerably reduced.

For ITMS 2.0 you can reduce the running distance by 32%, whereas 3.0 is under development still with a goal of 40% increased operability due to improved range. Regarding alternative vehicles such as fuel-cell vehicles (FCV) and hybrids, we have a variety of options in terms of air conditioning, either using a heat exchanger, heat pumps, ITMS 2.0, or ITMS 3.0. Depending on the customer requests or application we can provide an adequate solution.

Do you have a release date for ITMS 3.0?

The project is currently underway with the goal of completion by the end of 2024.

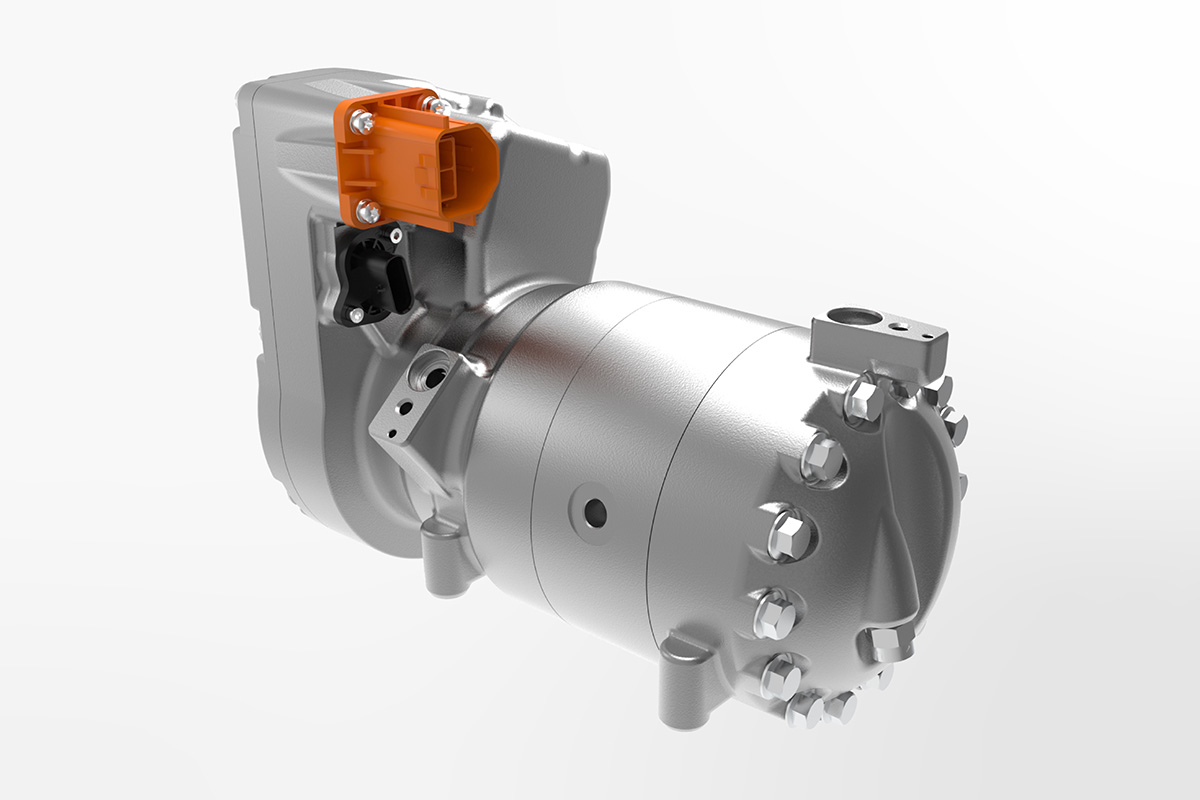

In recent times, carbon dioxide compressors have risen in popularity due to them being environmentally friendly and CO2 being a natural refrigerant. In 2017, you began the production of CO2 compressors for the first time in the world on a mass production scale. As a firm with a large global market share in compressors, what makes your CO2 compressors superior to more conventional products?

I mentioned the three core values of our company, those being quality, global, and the environment. In 2017, upon discussions with our customers, the use of CO2 came up as a natural refrigerant that is less harmful to the earth. However, we know that CO2 compressors are very difficult in terms of technology since they require another digit of high pressure. Therefore, we decided to take on the challenge of changing our mindset from the desire to improve our technological capabilities to the desire to be a company that makes every effort to care for and contribute to the global environment.

We have three unique aspects of our CO2 compressors that I would like to talk about now. One of the technological advancements we have developed here is our aluminum die casting technology which can withstand high pressure and high heat. Another unique aspect is that since we utilize gas at high pressure with the CO2 compressor, there is a vulnerability to leakage, however, since this development we have improved our sealant technology which allows resistance against high pressure. Finally, we have significant noise reduction due to improvements in the design. The issue that the variable capacity compressor has is it becomes harder to control with higher pressure, so in that case, we have applied a cutting-edge mechanism to control the high pressure.

With the rise of environmental awareness globally, automobile manufacturers are now considering to shift towards environmentally friendly refrigerants, and those could be a strong choice either CO2 or propane gas. We are doing R&D daily so that we can cater to both directions. General users and automotive manufacturers are becoming more attentive to the environmental regulations in place such as polyfluoroalkyl substances (PFAS) regulations. We are uplifting our standards so that we cater and comply with all regulations.

CO2 Compressor

Could you tell us the role that partnerships play in your business model and are you looking for any new partnerships in overseas markets?

Partnerships do play a key role in our company’s strategy and there are three different types of partnerships we engage in. One is collaborating with customers, another is working with similar companies in the same industry, and finally, we have partnerships with suppliers. Sanden has established a partnership network with multiple companies as well as partnerships with automotive manufacturers.

Speed and accuracy in development are key what determines success so focusing our R&D only on our own company would lessen our capabilities. Although some partnerships may be within the same industry, we find constantly the new and best partnerships to augment all involved. It is not only customers and suppliers either, and working with academia is also an important part of our business model, not only with domestic institutions but also with US and European universities. Currently, we are collaborating with these institutions to develop new products. The switch to EVs is being considered a once-in-a-century breakthrough, however, it might be overstating things a bit, but it is more like a once-in-a-year breakthrough right now. The speed of changes is so rapid that we should always play catch-up. We feel that in order to be at the forefront, it is now very important to build cooperative relationships with other companies and respond together.

This year our company is celebrating its 80th anniversary. The spirit of the company's founding, "Let us Develop with Wisdom and Prosper in Harmony," is the cornerstone of our actions, and the constant challenge and innovation of all our global employees have been our tradition cultivated over the past 80 years.. Thanks to the predecessors of the company that took tremendous efforts to overcome challenges and obstacles which allowed them to pass the company down to the current generation. For us as this new generation, it is important for us to continue to face new challenges and Innovations.

Are there any mid-term goals that you have set for your 80th anniversary?

That plan consists of transforming ourselves from a component supplier to a full solution supplier. We have set a target to become the number three company in the compressor industry and the number five company in the ITMS industry, however, seeing recent moves, we are pretty sure we can aim even higher than that.

One way of reaching these goals is leveraging your vast international network, expanding to the Americas, Oceania, and Asia. Moving forward, which countries or regions have you identified as key for the growth of your firm, and what strategies are you employing for the international part of your business?

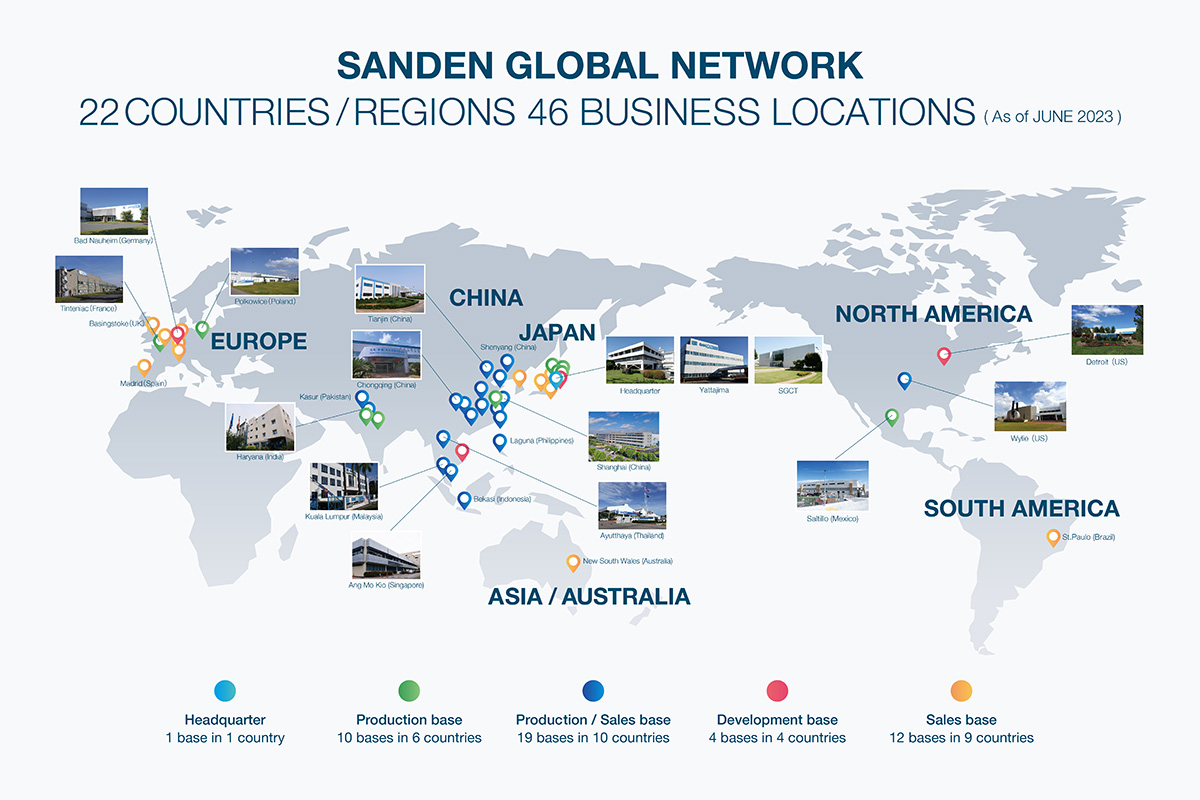

Based on the basic concept of manufacturing and providing products close to our customers, we now have a network of overseas offices in 22 countries.. Our priority right now in our global strategy is China, Europe, and then the US. We have felt that the US in particular needs to be further strengthened in the future so recently we restarted our electric compressor manufacturing locally. We are also studying areas like Africa and the Middle as potential locations for local production.

Imagine that we come back in five years and have this interview all over again. What goals do you hope to achieve by the time we come back for that new interview?

When you come back in the future, I hope to explain to you how Sanden products have become more of a key critical component of cooling and heating in automobiles. I have two reasons for this goal. We are an independent company, so we can work with all sorts of customers. Because of this, we have a wide range in our customer portfolio and it has enabled us to understand the needs of each customer more deeply. By learning and combining these experiences and accumulated knowledge we are able to standardize some processes and customize our service for each customer.

Another strength that we have is the Hisense Group, which is our dominant shareholder and a global manufacturer with particular strength in TV manufacturing and high-speed internet. We are currently in discussions to create a new smart system with Hisense by building a system connecting the car air conditioner with a home appliances. Hisense also possesses advanced control technology for traffic signals and smart traffic systems, and is conducting numerous research and development projects that incorporate this technology. One of these efforts is to realize efficient temperature management by synchronizing traffic signal control and traffic volume to control the temperature of air conditioners for automobiles in advance.

Finally, I would also like to talk about the four values that are important to Sanden's future growth, both internally and externally. Those four values are transparency, respect, support, and trust. These four keywords are the values that we share with our employees and customers. In order to realize an international company that will last for more than 100 years, we will strive to achieve our vision and mission and become a full-solution supplier through daily challenges and reforms based on mutual support, transparency, and respect, and the trust that comes from that trust.

Interview conducted by Karune Walker & Sasha Lauture

0 COMMENTS