NAIGAI develops high-quality socks that help resolve issues which concern the elderly, pregnant women, and people with disabilities.

What do you believe sets your company and other Japanese apparel makers apart from regional competitors? What do you consider to be your core competencies and strengths?

I understand your question regarding our company's core competence and how it relates to our company as well as Japanese companies in general when we talk about monozukuri (manufacturing). We are refining our core competencies with an emphasis on creating value beyond price. This mindset has been deeply ingrained in our fundamental perspective of monozukuri, and it has accumulated as a core value throughout our history.

For instance, when we manufacture and procure products, we primarily prioritize value and quality over cost. We place significant emphasis on delivering value and quality, and once that is achieved, we consider our next approach. This way of thinking sets us apart from other companies.

Our company was founded in 1920, and right in the midst of the covid pandemic in 2020, we were marking our 100th anniversary. Going back to our early days, Japan had not yet Westernized its clothing industry, and most socks were imported from the USA and Europe.

Our co-founders, Koichi Yoda and Masakazu Kobayashi, had the opportunity to work for a domestic trading company in New York after graduating from university. This experience provided them with a global mindset and perspective.

Recognizing that Japan was heading towards Westernization, including the clothing industry, their dream was to create their own products and sell them in both the domestic and overseas markets. Hence, our company is named "Nai Gai", a combination of "domestic" and "international" in Chinese characters (kanji).

Upon their return to Japan, as the country did not have knitting machines at the time, they imported them from North America and Europe. These machines were the foundation for establishing our Nagoya plant.

Imported products during that period were not of high quality, so our company's primary policy has always been to prioritize quality. This policy has been upheld for the entire 100 years of our establishment. Our goal is to provide value that exceeds customer expectations.

"Socks for Everyone" みんなのくつした

You mentioned the importance of prioritizing quality above everything else since the inception of the company. However, we currently find ourselves in an era of fast fashion, where the focus is on low-cost production and quick replication of products. While this approach may be convenient for consumers, it takes a toll on the environment. Socks, in particular, have gained a reputation as disposable clothing items. How are you working to change the perception of your main product as being a sustainable product? Could you share some insights into your initiatives for sustainable development?

When Japanese companies discuss the sustainability of their products, they often focus on aspects like the use of renewable fibers or reducing CO2 emissions. However, from our company's perspective, it's primarily about avoiding waste. This mindset has been ingrained in our company since its inception and continues to guide us today.

To illustrate this, let me talk about my own closet at home. I have around 50 to 60 pairs of socks, which is more than the average person, but when I consider the number of socks I actually wear on a daily basis, it's only about 10 pairs. These 10 pairs are the ones I find comfortable, matching with my attire, and are durable. Interestingly, most consumers, including myself, are not consciously aware of why we heavily rotate these specific 10 pairs of socks. It's just what naturally happens.

Even when many socks are bought, they end up sitting in the closet and unused, due to comfort or coordination issues. NAIGAI’s approach is to focus on creating socks that will be used unconsciously and daily. By concentrating on these high-quality, frequently worn socks, we aim to reduce waste. Our policy is centered on not creating and selling wasteful products.

Now, moving on to a question about the higher cost of your socks even compared to those produced by other high-end makers. How would you convince me to pay the extra 500 to 1000 yen on purchasing NAIGAI products?

Comfort is subjective and varies from person to person. This brings us to the next stage of our evolution, where we believe it's necessary to visually demonstrate our quality and provide scientific evidence for the benefits of our products.

Merely stating that our socks are of high quality or verbally expressing their superiority is not sufficient. Customers need to experience our socks first-hand. Visualization and scientific proof will be crucial in addressing this challenge, although I acknowledge it is the most difficult aspect.

While I can discuss our technical advantages to convince you to buy our products, it ultimately depends on whether these technical features align with your personal values. To truly understand the benefits of our products, you would need to try them.

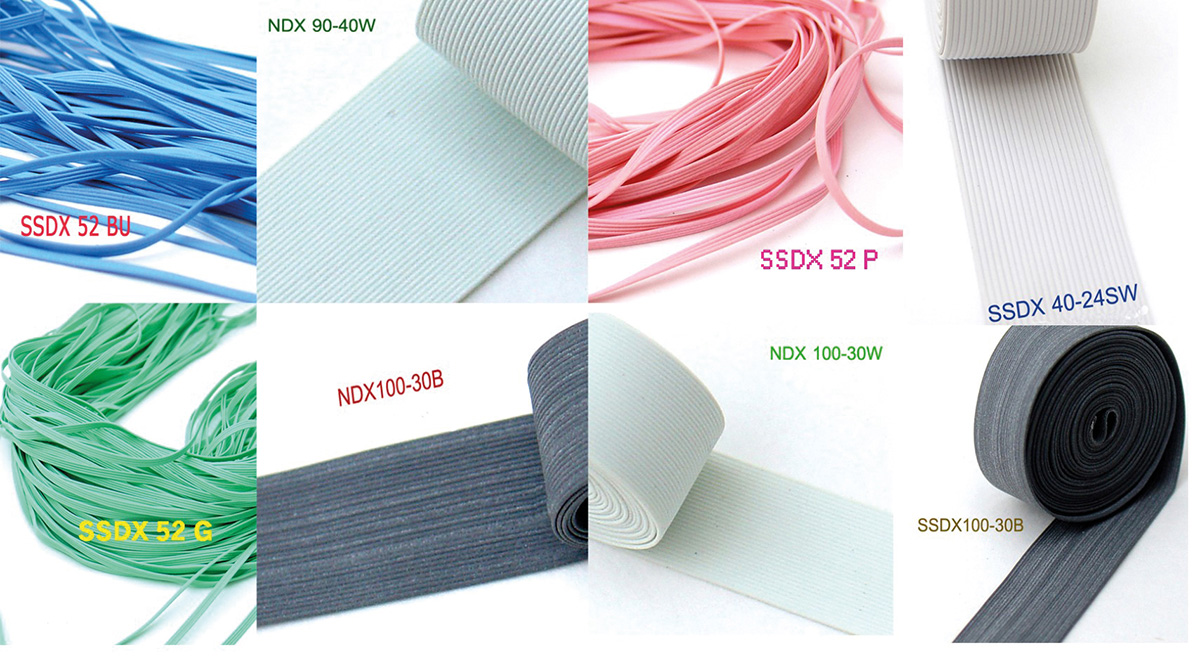

Speaking of technical points, let's consider our NDX brand, which features our unique rubber yarn. This rubber yarn was developed over 60 years ago by our company's founder. Initially, socks used natural rubber for this component but later was developed.

The choice was between natural rubber bands and spandex for the top part of the socks. Our founder recognized that this specific area is where customers often experience concerns, such as the socks falling down or causing friction and discomfort. Thus, our founder aimed to address this issue by creating an optimal rubber yarn for socks.

The challenge was combining the softness of natural rubber with the durability of synthetic rubber. Natural rubber is soft but lacks durability, while synthetic rubber offers durability but is not soft and leaves marks on your skin. Our founder's goal was to develop an ideal rubber yarn that combines the best qualities of both materials, leading to the creation of our NDX product.

The difficulty lay in the fact that the sap of natural rubber and synthetic rubber do not easily mix. It took considerable time to develop the technique to successfully blend the two materials, and we eventually achieved it. Other apparel normally uses spandex, which can cause discomfort and leave marks on your skin. In comparison, NAIGAI products are soft and durable.

For instance, our competitors also use our NDX rubber. What I wanted to convey with this presentation is that we have all these superiorities. Other companies are using our technology, but it's difficult to convince customers the significance of NDX. If I could spend five minutes with you in person, I could explain this better.

It's challenging for an individual consumer to fully grasp and understand it, but once you take a look at our socks and try them out, you can truly realize that the rubber is extremely soft yet durable.

These days, many cheap socks are coming from countries like China, Pakistan, or India. Most of them use natural rubber for this part of the socks, which leads to deterioration after washing them several times in the washing machine. The rubber in that part gets cut or comes out. However, this doesn't happen with NAIGAI products.

NDX products

On the other hand, other apparel uses spandex, which can cause discomfort and leave marks on your skin. In comparison, NAIGAI products are soft and durable. That's why I tend to choose NAIGAI socks from my closet all the time, even if I'm not consciously aware of it. I hope more and more consumers will feel the same way.

Let me explain one more technical point, regarding our five-finger socks. It's not just a matter of having five fingers in them. Initially, we manufactured these socks using glove machines, which made it difficult to adjust the length of the fingers, so putting them on and taking them off was hard.

We wanted to provide comfort to our customers and make it easier to put on and take off the socks. The solution was to align the length and volume of each finger with the actual toes of people's feet.

However, we couldn't achieve this with glove machines alone, so we developed a three-dimensional knitting technique using a new whole garment (knitting) machine. We discovered that only this machine could accomplish our new technique. Currently, we utilize the whole garment machine to produce five-finger socks, which is easy and comfortable to wear.

3D five finger socks

Your latest design concept, called “SUASiC”, is the world’s first “sock for your shoe”. It offers the appearance of bare feet, which has become desirable in recent fashion trends. It also provides odor resistance, slip resistance, and incredible comfort. What was the motivation for creating such an outside-the-box product like this? Secondly, people wearing shoes barefoot often have problems with blisters on the back of their heels. How does your product address that specific concern?

The motivation behind creating such an innovative product was the concern raised by many women in the summer. When they wore pumps or sandals barefoot, their feet would become sticky, slip, or even get hurt. It could also damage their shoes.

To address this issue, some women wore a type of socks that are shorter and don't show from the outside. However, the concern was that the heel part would often come off and become uncomfortable. Some women didn't want to go barefoot in their sandals.

The front side of this product is made from sock material and knitted using a sock knitting machine. We use antibacterial and anti-odor materials for this. Since it needs to fit all kinds of shoes, including sandals and other types, we have to adjust the thickness so that it's not too thick.

If knitted on a normal sock knitting machine, it became thicker. However, we made an effort to make this product as thin as possible. We want consumers to be able to use it every single day. You can easily wash it in a washing machine and just let it dry. It dries very quickly, usually within just a few hours, so you can use it again the next day.

You'll notice that the other side is slightly sticky. This adhesiveness allows the shock-absorbing material to use a material with an excellent grip that provides a better fit with the shoe.

The product doesn't slide around in the shoe, providing a solution to issues such as friction and blisters. The gripping capability of the fabric on the foot prevents any sliding and eliminates the discomfort you mentioned. We are currently developing it for men also.

“Socks That You Don't Wear" はかないくつした

That's interesting to know. In countries like France, Spain, and Portugal, men exclusively wear espadrilles in the summer, and we often face issues with the back of the foot and blistering. I believe your product would be highly sought after by espadrille companies.

We call this product "Socks That You Don't Wear."(はかないくつした) However, when we look up the definition of socks in the Japanese dictionary, it states that socks are apparel products worn on the feet. But this product is not something you put on your feet directly, but rather inside your shoe.

We had internal discussions about whether it was appropriate to use this phrasing, but we decided to move forward with it. When we approached buyers in the sock department to sell this product, some would argue that it's not a sock, but an insole. They suggested going to the shoe department to sell it, so there's still some confusion about categorizing it.

After that, we had a brainstorming session to redefine the role of socks. Ideas came up such as warming your feet, protecting them from injury, keeping the shoe environment clean, and maintaining foot hygiene. We realized that socks are not just limited to the wrap-around type. The development of “SUASiC” was really a transformational period for us, which changed our fundamental vision of socks.

You talked earlier about this ambition to increase your product reach overseas as well. As we're representing an international magazine, this is a point that we're particularly interested in, both in terms of “SUASiC”, but also your other product offerings. Can you give us some insight into how this vision? Are there any particular markets that you are interested in? How do you see the further development of the NAIGAI brand taking place overseas?

Regarding our ambition to expand overseas, currently, we don't separate between the domestic and overseas markets as a company. We are going through an evolution and have positioned ourselves as a leg solution company for our 100th anniversary.

We aim to resolve the issues and concerns people have with their legs and feet worldwide. It's part of our rebranding effort. We are already supplying Asia, America, and Europe, including socks under several brands.

However, we don't want to limit ourselves to these markets. We believe that people from various regions, including America, Europe, and Asia, share similar concerns for their feet. If there's a need in a particular market, we want to approach it with our products.

Of course, it is said that the population in Japan is going to decrease from here onwards. It is projected that in 20-30 years, our population will decrease by around 100 million people, and the aging population will continue to grow. This is a fact and the future reality in Japan.

Our focus in the domestic market right now is to address the issues faced by the elderly population concerning their legs and feet. They often encounter barriers such as foot pain, joint pain, and their hips may hurt, or they may have swelling feet. Therefore, we are working on developing socks and services to address these specific issues.

Additionally, we are also developing products for the Femtech sector, aiming to contribute to resolving women's issues by contributing to their feet. These are the two main areas we are currently focusing on in the domestic market, but we believe that these products can also be expanded to the worldwide market. Hence, we are committed to developing our products for these two sectors.

Regarding the first pillar, which targets the aged population, it is currently estimated that there are around 36 million people in Japan who are over the age of 65. While the Japanese population is declining and the market is shrinking, we, as well as other companies, used to have a mindset of producing products primarily for healthy and non-aged individuals.

We would create various functions and push services to cater to that specific market. Even if those individuals expressed a desire for sustainability and reusability, we would encourage them to buy more products, resulting in declining prices and generating waste.

However, when we consider the needs of the elderly, handicapped, or pregnant women who face various barriers in their daily lives, we realize that the products and services provided to them have not been sufficient or effective. As NAIGAI, we have shifted our mindset and recognized that despite the shrinking population and market in Japan, there are new market needs and business opportunities that we can focus on.

For example, I’d like to showcase our “Socks for Everyone” (みんなのくつした) product line that we have developed in collaboration with a company called MIRAIRO which aims to create value from barriers and resolve issues faced by people with disabilities.

Initially, the sock was intended for the aged population, but we discovered that the concerns experienced by disabled individuals regarding their feet and legs are quite similar. We conducted roundtable discussions with people with disabilities to directly understand their sock-related concerns. For instance, people with disabilities in their hands or those who use wheelchairs find it challenging to open the sock's cuff and put their legs in. They also mentioned having swollen feet, which caused discomfort when wearing socks. Hence, we identified the cuff of the sock as a significant issue to address.

Furthermore, individuals with visual impairments were also part of our roundtable discussions. They mentioned difficulties in distinguishing colors, leading them to purchase multiple pairs of identical black socks by getting socks of the same standard. This was because they knew that the same standard socks would always be available, eliminating the need to inconvenience others or to ask the store staff for assistance.

Based on this feedback, we aimed to create a standard, long-lasting product that would survive many years. In regular products, you might see plastic pins used for packaging.

We discovered that people with vision disabilities find it difficult to cut this portion because they might accidentally cut off part of the sock or lose the plastic pin, which can be hazardous if stepped on later. This pin serves the manufacturer's and retailer's purposes, not the wearer's, so we came up with a concept where there is no pin at all, and with one simple action, you can slide the sock on and off your foot, and in and out of its packaging.

“Socks for Everyone” みんなのくつした with easily removable packaging

Additionally, we made the rubber in the cuff expandable and secure with a woven portion at the heel to prevent the sock from sliding off, even though it is expandable. Moreover, for individuals with vision impairments, we added size indications. One line represents sizes 22 to 24, and two lines represent sizes 24 to 26, allowing them to easily determine if the socks are a pair by touch.

We were able to understand that the concerns of the aged personnel and people with disabilities are quite similar. Thus, this product was developed based on direct feedback obtained from focus groups consisting of these individuals.

What about the second pillar you mentioned, Femtech?

Regarding the second pillar, Femtech, the Femtech market has been expanding year by year, and we entered this market three years ago. Our aim is to address the unique issues faced by women at different stages of life, including adolescence, maturity, and aging. We focus on improving blood flow to resolve these issues.

The product we introduced utilizes a terahertz artificial ore called TERAX, which is known for its trillion times-per-second far-infrared molecular vibrations. We grind this mineral rock, combine it with a binder, and print it onto the sock. This promotes blood circulation and blood flow throughout the body and increases body temperature at the extremities.

TOTONO with TERAX printing

It is said that 50 to 60% of the human body is composed of water. By utilizing this artificial mineral, we can create vibrations that positively impact blood flow and other water substances in the body. This can help address issues such as cold fingers or irregular menstrual cycles.

Normal water does not exist as a single molecule but as a large, clustered molecule. When far-infrared radiation is irradiated on water, the hydrogen bonds of the clustered water molecules are broken by vibration, and the water molecules become small single molecules. The same effect occurs in the blood, and the blood that was clustered and had poor blood flow becomes smaller and smaller. The blood circulation is accelerated by the fragmentation of molecules caused by the irradiation of far-infrared rays.” We have received positive feedback from customers who have directly contacted our customer call center, reporting improvements in issues such as cold fingertips because of our product.

As I mentioned earlier, we strive to become a leg solution-oriented company. To achieve that, we understand that we can't solely rely on our traditional monozukuri manufacturing approach. That's why we have reorganized our structure and established a technical division responsible for development and inspection, ensuring a solid infrastructure for the future.

For example, let's consider the “TOTONO” product that we introduced. Our technical division is responsible for verifying whether the product actually improves blood flow. We also discussed the significance of comfort. This division ensures that our socks provide the desired level of comfort.

Naturally, we require supporting data to convince our customers to choose our product. To achieve this, we established the “NAIGAI Lab” a few years ago. Within this laboratory, we have installed several measurement machines.

We also have machines that apply various pads to human bodies to measure muscle motion and determine the center of gravity. In essence, we have implemented numerous research.

NAIGAI Lab

In order to market our socks, simply discussing our manufacturing process is insufficient. We need concrete evidence to substantiate why our products are superior. So far, we have provided evidence to prove the durability of socks through washing resistance and dye fastness tests.

However, we have not focused enough on obtaining evidence related to our product's functionality and comfort. Unlike other companies, we aspire to acquire such evidence and become a leg solution company. Hence, we established the “NAIGAI Lab” to facilitate this pursuit.

0 COMMENTS