Nakamura Tome explains how their multi-tasking machines can create greater operational efficiency and be a key tool for the island nation to combat a declining population.

Over the last 25-30 years, Japan has seen the rise of regional manufacturing competitors who have replicated Japanese monozukuri processes by taking advantage of cheaper labor costs and pushing Japan out of mass industrial markets. However, Japan is still a leader when it comes to niche BtoB fields. How have Japanese firms been able to maintain their leadership despite the stiff price competition?

Our field is a little bit different from normal machining. We focus on multitasking machines which feature combined processes in one machine, so our customer needs just one machine. Four processes in one machine and this is a fast-growing market which needs stable and flexible machines. They need capable machines that combine processes and make it easy to automate machines and reduce the human interaction required. If you use four machines, you need four operators, but if you only use one, you only need one operator. It dramatically reduces human tasks. Also, when it comes to automation, if you use four machines, you need four robots, but if you only use one, you only need one.

Our philosophy is now well received all over the country and at the time, I said that stable machines and machining capability reduces downtime. This is very important. In this field, it is better to have incremental improvements in Japanese manufacturing strength, and also quality control, of course. Now there have been many developments in this area using the software side, the machine side and the automation side too. This is what makes the difference. For example, whether it is a small electric component, PC or a refrigerator, they have slightly different features, so if the quality improves, the customer cannot feel it, so it needs better design and branding now.

In our machine, the design and branding are also important, but also it is important that a customer needs a real machine, and if they mimic or replicate, that is a pity. If the machine cannot machine the material well, we just call that scrap steel. That is not our machine. This is totally different, and if we make a good machine which is stable, the customer will continue to buy our machines now because it is one that will be more automated and flexible. If the machine stops, it makes a big difference to the customer’s factory. I think that is why the Japanese strength is used and valued in our field right now.

If we look at your company, Nakamura-Tome is utilizing IoT to achieve visualization of factories. In addition to this, you are also offering a lineup of software to automate certain customer processes. Can you outline some of the strengths of your software, and what other digital tools are you looking to implement into your business?

Firstly, I will tell you about our direction. This is our purpose in manufacturing, and ‘manufacturing is so interesting’. For example, a knee implant, so it will go in the human body. The implant is an artificial bone on the knee. 30 minutes ago, this part was just steel material. 30 minutes later, it can be a completed part made by our machine, ready to go to someone’s body. This is a miracle. We can see this processing in front of the machine, and we are always surprised, so manufacturing is so interesting. In manufacturing, I think all factories have tough jobs and many burdens.

Of course, every industry has burdens, but if we fill up with them, we completely forget the manufacturing industry. “It is a heavy job and it is a tough job, so I will go to another industry.” I saw that many people thought this way. Every factory had a problem. I think I visited more than 150 companies who were our customers. I went to a super clean and cutting-edge factory in Germany. This customer also had many problems and I was surprised. We changed this with our machines and services, and our purpose is to cut the burden of manufacturing. Our machines cut not just one piece, but also the burden of manufacturing, and create a future where people can enjoy manufacturing.

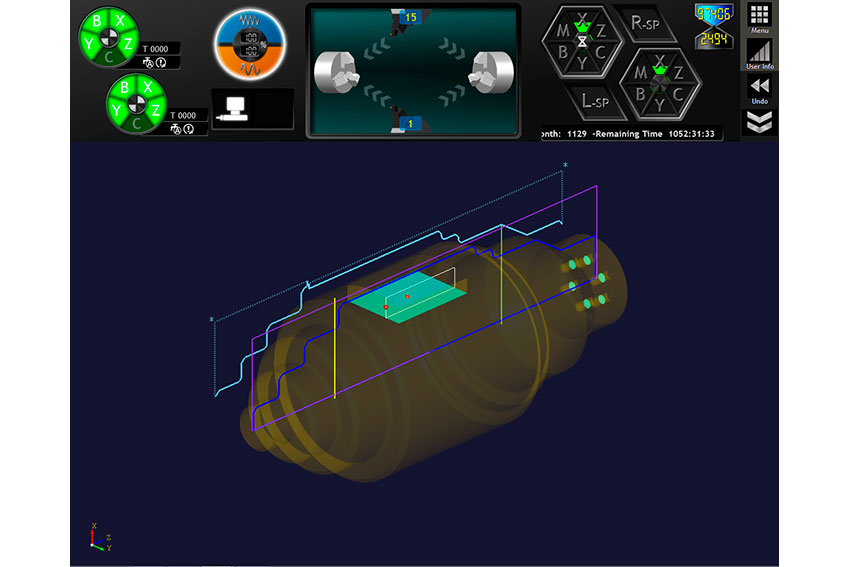

I think this is the whole answer to your question. To achieve this goal, this is our 3D Smart Pro. This software is unique and we put a 3D model on the control panel, automatically program it and then is make the decode/encode, we call it the ISO-code program, which is commonly used. After we make it, we can fix it easily. For the first program, and for a simple pattern done manually in 240 minutes, the 3D Smart Pro takes about 30 minutes. About a 90% reduction. Of the setup time, about 60% is programming time.

Set up is such a tough job, especially on a multitasking machine. 60% is spent on programming, especially on high mix, low volume production. There is a lot of high-based robot production in the world right now, compared to 20 years ago, and it is growing. Programming is key, and we automate with our technology, by ourselves. For example, 3D Smart Pro and it has many functions - more than 100 functions included on our machine, for free. We do not take any money for this. If you buy the machine, you can use these functions for free because I want to reduce the burden of the customer.

3D Smart Pro software

The four key elements of parts manufacturing and machining are the raw materials, the latest and most advanced machinery, advanced CAD/CAM software, and a controlled production environment. Obviously, this means that there is a decreasing need for workers in this setup due to the IoT as well as big data. In such an automated and controlled environment, what is the role of the engineer?

We also use CAD/CAM, for example, and when you use it and to get a good trajectory or good machining parts, you need to have know-how, and that depends on the person. If you choose the right person to use CAD/CAM, it makes a good part. If you choose a low skilled person, it is totally different.

Sometimes there are collisions and sometimes there is a low-quality surface which result in low quality parts. It is the same with automation. If you set up a large automation system, and of course factories have many, everyone thinks that you just push a button, and the automation is done. This is not true. There are many tasks to get rid of downtime. Of course, it is a short downtime, just one or two minutes, but if you cannot get rid of it and it is during a nightshift, in the morning, they will come to the factory and find the systems has stopped. If they planned for 1000 parts in the night, it could result in just 10 or 20, so this has a big effect on the customer.

I think the difference is that 50 years ago, human skill was the focus. We have operations now, but it has shifted to becoming a more cerebral job. For example, to get rid of the tasks through automation and reduce downtime, it requires use of the brain, and making good parts also requires use of the brain, so human-related jobs will increase, I think.

We know your business can be divided into four main product divisions. Work machinery, automation and software, as well as optical mechanics. Can you tell us which product division is your current focus and which do you believe has the most potential for future growth?

We have always said that three areas are important. The first is machines. We are in the machine tool industry and if we get rid of machines, we are not needed. The second is functions, which include the software. Thirdly, the automation. This is for not just the machine tools but is also the same for the optical machines. These three elements are mixed together to create value, but I think that the key element is always the machine. If the machine is good, we can use the software to its full potential and achieve automation. If the machine is no good and cannot produce well, even if we added good functions, software and an automation system, it would still be poor. We are very careful about that.

Apart from the machines, we are also focused on IT and automation but nowadays I think it is turning on the real value. We focus on the machining because we also develop machines for that. If we just catch up to the latest cutting-edge software, the result of the machining could be poor, so we focus on the result, which is measured by the machine design, software design and the automation. As such, we developed machines from the viewpoint of machining, and we invite many members from multiple departments – manufacturing, service, design and sales – to make one machine because they are all involved in machining. We set the goals, the setup conditions and the cycle time in the cold device and then make the machine structure-wise and spec-wise. This is important, and I want to say, the key element in machines.

JX-200 machine

One of your latest products is the JX-200 multitasking machine equipped with the world’s smallest class tool spindle, as well as having a milling speed of 6000. How were you able to achieve these unique features when developing the JX-200?

It was tough because the tool spindle is compact. If you reduce the motor size, it is not so difficult: just put a small motor and short spindle, but we do not want to do that because if we select a small motor, the machining capability is reduced. That is troublesome and it is totally different from my philosophy, and we put the same model and components on the tool spindle, creating more space and a short and compact spindle. It is also powerful. When we had visitors to our factory, I presented this machine and I think that our guest was surprised. 9mm is the turning cutting depth, with a 50mm diameter cutter and a 16mm diameter end mill creates an amazingly high cutting condition.

SC-200II machine

Another product launched this month, in November 2022, was the new precision CNC multitasking lathe, the SC-200II. What are the advantages of this?

The machine’s concept is “next level machining”, which means high machining capability. It is an 8-inch class single turret machine and also we can include 10-inch chuck.

too because this machine has a big swinging diameter, which means it has a big machining area. If you have big parts – 700mm in diameter – we can machine them from the front and produce these big parts. It is like downsizing but for machines. It also has a small carbon footprint while being a small, compact machine so you could produce many types of parts, making it flexible. Nowadays our customers cannot survive on just one sector or part and they are able to get many opportunities from various industries because our machine is flexible. Our machine can smoothly change between different types of parts, but other machines find this difficult. This machine now has a reputation among our customers for flexibility.

Can you tell us a little bit more about your R&D strategy, and are there any products or technologies that you are currently working on that you would like to showcase?

The core philosophy, as I said, is a cut above. Our customers have a lot of tough jobs. We collect data, customized information at a global level, and at the moment we have one distributor for each country, and we have many partners. I think there are at least 40 partners overseas. A partner is like our member. They are no different to our employees. Some relationships are more than 40 years old, for example, in France, the USA and Italy. These kinds of relationships are one of our strengths and we also fully understand their business at the corporate level, and they also understand ours.

Also, we share our development road map, and we can communicate and exchange information most of the time. Now we have made a department for collecting data worldwide. We hired some employees who joined us as experienced hires, and they now collect this data. I am focused on opportunities and with five others, we visited many countries and collected data. Now that we have that, the organization is better and we do not need to rush.

We have many models but now the priority is the multi-turret machines. Multi-turret means dual turret or triple turret and the two-turret machine and the two-spindle machine is like that. Firstly, we start with the upper two turrets, which means the left-hand side is simultaneous machining with high production and the combined process. With a combined process in one machine means the cycle time is longer, but in these two or three turret systems, the cycle time can be shortened. Therefore, in the middle of mass production, the user can use this machine. If you use one turret and three axes, meaning functions, one turret is not much for mass volume, so this is why we started with the two turret machines and then we developed two turret, upper and lower, machines. Upper turrets are more flexible, so two spindles can have two workpieces simultaneously, but the cycle time and machining time are different left and right, as they are different shapes. When the longer side is busy, the shorter side is finished already and can take a rest, and taking a rest is a problem. When the right side is finished early, the lowest turret comes to the left for simultaneous machining, so it will be balanced, and balanced means a faster cycle time.

This kind of philosophy is from our European customers because it is a relationship based on theirs’s and our partner’s idea. We come back to our headquarters, everybody discusses about how to realize our customer’s idea. The customer cannot tell what they need every time. Sometimes they do not know what the problem is with the product. We correct the problem fast and then we make the machine. The problem is, of course, related to the machining and the setup time. Then we make the machine, so this kind of model is, I think, really interesting for many products and we always say it is based on value. If there is no value, there is no meaning. We set the workpiece and we set the customer and what value is important for them, and how much they can pay for this value, and then we set many specifications. Value does not mean spec. Value is about the customer making money or gaining some benefit.

Are you looking for new international partners to collaborate with?

We focus on entering new countries early. For example, now some nations are growing at the industrial level and they need good machines. Initially, they use simple ones but would gradually change to multitasking machines. This is a trend for all countries. In a new country, we always use partnerships. Firstly, we set the contract with the partner, and then strongly support them with our organization because in some countries like India and Vietnam, the user needs a commitment from the makers. Therefore, we set up a new organization in India and Vietnam, but we still use collaboration, and we still have contractors as partners.

You have overseas operations in countries like the US, Taiwan, China and Vietnam. All these countries are different in terms of their income and economic levels, and as a result, worker skills and equipment quality vary, which can have an adverse impact on the final product. How are you able to ensure the quality of your products in your overseas operations?

Our machines are not simple but not difficult to use. Our partner knows the machine well, sometimes better than us in some respects. In many fields, we win, but sometimes they have an advantage, especially in the relationships with local customers. On that, we cannot compare. They have a much bigger network. They know the application and how to use the machine, and how to service the customers in local areas. They just lead and we follow. New functions and new machines sometimes need a little bit of help from us. Nowadays, global customers have many plants overseas in, for example, Asia, Europe and the USA.

Over the last two years, COVID has caused many disruptions to shipping and logistics. Quarantine measures have impacted human resources, and the grounding of commercial air flights has restricted shipping capacity. In addition to a near tripling of oil prices, 77% of international ports reported delays last year. How have these challenges in global shipping and logistics affected your business, and how did you overcome them?

The global shipping and logistics problems are troublesome. Currently we are fighting them together with many of our members. It has been alleviated a little bit, but one or two years ago, it was really bad. In order to fight such problems, we need more logistics partners, and we already increased the number of these compared to two years ago. I think we need the capacity to make a network for each country, and this would also be helpful for our partners. We also need to select routes for shipment. If there are several routes, for example, a product is shipped from Japan to the USA is sometimes routed to Mexico, and then it needs to go by truck, so alterative routes are important. Sometimes we need immediate action for the customer and some customers that need, for example, aircraft shipping for the machine. Sometimes they request it, but it costs more than the machine.

Moving forward, what other countries or regions have you identified for further expansion into, and what strategies would you employ?

As I mentioned, we focused on collaborations with partners, and we leave the partner to do as they want locally. This strategy is important for us, but I think that in many countries, we sometimes need to provide a lot of support to a partner because as I said, it is a global customer program and also, sometimes there is new product support and new function support and training.

Due to COVID, it is difficult for them to come to Japan. Otherwise, normally, many application engineers and service engineers come here. For example, in one month, three or four people would come and train in our factory and see how to make machines. This routine is a little bit difficult now, so we made a company in Europe, and we already made Nakamura-Tome Germany and Nakamura-Tome Europe, but this is not for direct sales. This is to just help partners. We need to make an information and communication hub, and then the technical support side will be stronger, as well as the business side. This is a little bit different from our former ideas. For example, the former president, my father, believed our local dealers should commit 100%, but now I think our company’s commitment is 30%, and 70% is the dealer’s commitment.

Which specific geographic region do you believe has the most potential for your company to grow?

Nowadays, I think Southeast Asia and India are important. Southeast Asia is an alternative to China, so many foreign investors put money into Vietnam and Thailand, for example. Many big Japanese companies are located in Vietnam, for example, in our prefecture, some companies hired Vietnamese operators and three or four years later, they went back and set up their own companies. This has happened in Japanese companies, so now it is accelerating investment in Vietnam. Now we have set up our there, and also we will open in India I think, in January. For India, it is important to hurry up and get customers.

Which are the main industries that you are able to cater to, and is there one in particular that you feel you can contribute the most to?

Nowadays, the electrical components, semiconductors, medical and aerospace markets are booming. Automobiles and construction machines are also big in Japan. Multitasking machines is a special field. It has been growing for the last 10-20 years because large volume production was reduced. Now in Japanese automobile companies, which are the kings of mass production, they are reducing their lot sizes for items, and they came to our company. 5-10 years ago, we proposed our machines and combined processes into one machine, but they did not buy them. Nowadays it is totally different. Now they call us about which machine is good. A lot has changed, I think. Even the Japanese automobile makers tried to change. Now there are no super large lots and it is a mid-range level or small lots for high mix, low volume production. The multitasking machines are a 100% match, suitable for many industries. Right now, I cannot select one industry. I think every industry will come to meet us because our machines can make everything.

Imagine we come back to interview you again in three years' time: what would you like to have achieved by then?

Our goal is to cut the burdens and create value so people can enjoy manufacturing. Our members love manufacturing, love machining and love the machines. Such members are rare. This is a big goal. Of course, sales volume wise and profit wise, we have aggressive goals. For example, we need to double our sales volume and it is totally different from here.

This is the long-term vision, and in order to achieve it, we need to spread the multitasking machines all over the world and all over the factory. In achieving this, I think we can create different value, so people can focus on new machines, new products and new work using their brains, not just their hands.

0 COMMENTS