Amidst the challenges of a rapidly evolving global market, Matex's fifth-generation president reveals a visionary plan focusing on specialization, international partnerships, and the pursuit of sustainable growth. With a legacy of over a century, the company sets its sights on the burgeoning fields of robotics and EVs, aiming to secure its place in the next 100 years of industry innovation.

Matex is a professional group for designing and manufacturing planetary gears, gearboxes, and transmissions. Planetary gear reducer and injection molded plastic are our main business areas. A planetary gear reducer is a gear reducer that has a sun gear and planetary gears.

Coaxial input and output structure enable a more compact design than the usual spur gear. A wide variety of diameters, sizes, and materials is available in our standard lineup.

Customization of gears, reducers, and actuators upon the user's request can be offered. A planetary gear reducer with low backlash has been developed.

A new gearhead has been developed using our popular gear unit LGU35. Matex will keep on challenging as your technical partner.

Can you provide a brief overview of your company?

I am the fifth-generation president of this company, following in the footsteps of my great-grandfather, who founded the company in Osaka Japan in 1921 and was succeeded by my grandfather, uncle, father, and I.

Before joining this company in 1995 at the age of 30, I spent a decade working for a securities firm. During that time, I had the opportunity to work in Sydney, Australia for two years. My background was in a different sector, so I had limited knowledge of manufacturing and technology. At the time, our company, Matex primarily focused on plastic molding. While we produced products like some gear reducers, these were not our core business.

Upon joining the company, I worked on discovering Matex's strengths and competitive edge. It became clear that our technological expertise in producing planetary gear reducers had the potential to drive our growth.

In 1995, the Japanese yen was remarkably strong against the US dollar, trading below JPY 80 per US dollar. We decided it was time to establish an overseas presence, although without conducting thorough research. Many Japanese companies were eager to enter the Chinese market then, but we lacked the necessary connections. At that time, we had a relationship with Sharp, a Japanese consumer electronics manufacturer. Their Philippine plant only wanted to directly import our reducers from Matex Japan instead of through Sharp Japan. But, without proper analysis, we made a unilateral decision to build our Philippine plant. I was stationed in that factory, and it was a hard but challenging experience.

A turning point came when Seiko Epson Corporation, a printer manufacturer, decided to establish a factory for inkjet printers. We supplied them with small plastic gears, and the orders from Epson gradually increased. This allowed us to maintain our Philippine factory. Fortunately, there was less competition in the Philippines than in China or Thailand, making us one of the limited Japanese suppliers of plastic components. Epson's support and advice were crucial to our growth in the Philippines.

Two years after our Philippine factory began operations in 1997, I entrusted it to a Japanese manager and our local staff and returned to Japan. I began contemplating our business strategy in Japan, where our core technologies revolved around plastic molding and reducer production. I saw the potential for combining these technologies to create high-value products.

In Japan, we collaborated with OMRON Corporation, a healthcare device manufacturer, to develop a product used in massage chairs with rotating and reciprocating motions. Our focus shifted from simply supplying reducers as components to producing a device that incorporated our reducers as a component for electric actuators in order to expand in this business area. In addition, we put more emphasis on our development and engineering teams. After that, we continued working with Omron to develop the mechatronics component for massage chairs.

As the capability of our electric actuators improved, I aimed to enter the field of robotics. However, this transition wasn't easy and required substantial time and effort. Unlike precision-focused gears, Matex's gears prioritize efficiency to transmit power more effectively, which is our main strength.

While precision could help reduce noise and vibrations, it could lead to higher costs.

Not just pursuing precision alone, but by incorporating unique innovations into the structure of the gear, we have achieved high productivity, high volume production, and cost savings.

Our Japanese factory primarily focuses on the commissioned production of electric actuators. In contrast, our Philippine factory, which began operations in 1997, and our Chinese factory, operational since 2005, are geared toward mass production, with their core technology centered around plastic molding. We didn't just limit our scope to robotics; we also sought to enhance the mass production capabilities of our overseas facilities, aiming to contribute to Matex's overall sales.

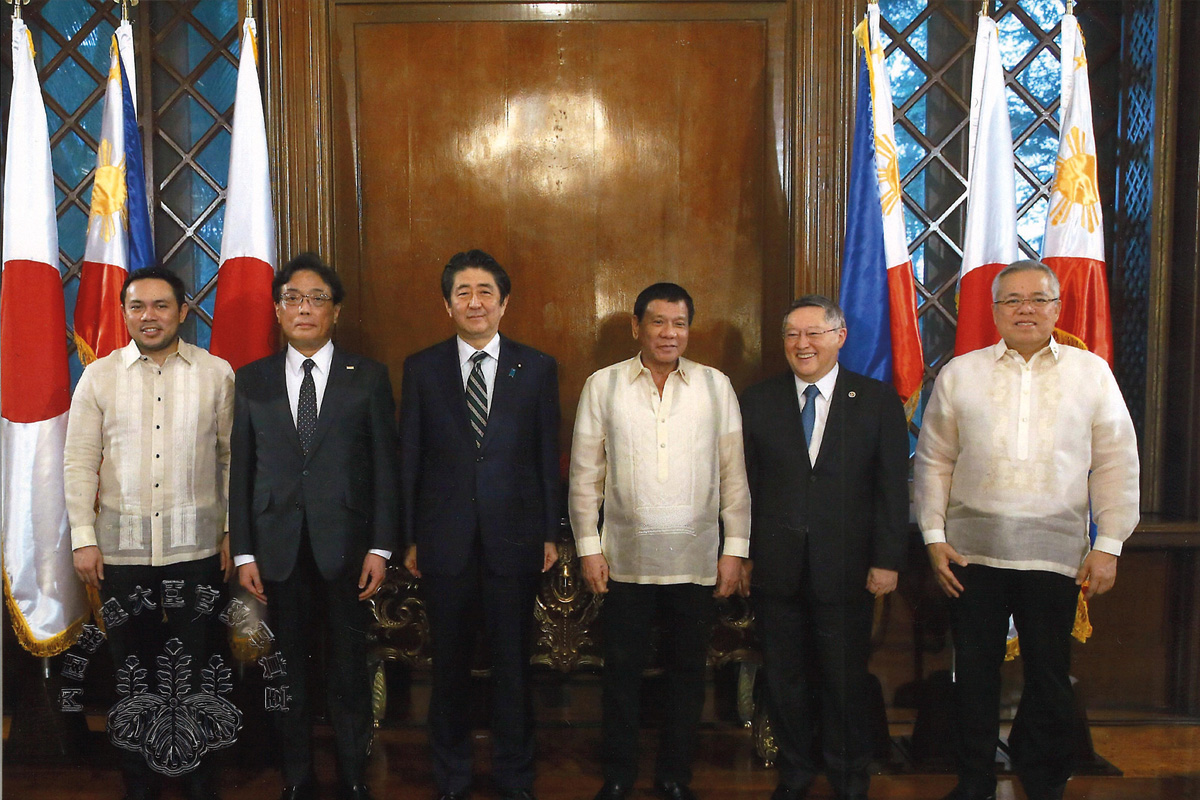

At the beginning of 2017, I had an opportunity to accompany the late Prime Minister Shinzo Abe to visit then-President Duterte as one of the representatives of the Japanese business community involved in the Philippines. By the end of the same year, we entered into a partnership with Sumitomo Heavy Industries.

Sumitomo Heavy Industries is a company with sales that are 100 times larger than ours. Despite this significant difference in scale, they treated us fairly. We were delighted they welcomed us as their business partner for this joint development endeavor. I will talk about the joint development with Sumitomo later.

Accompanied late Prime Ministar Abe at Japan-Philippine Business Forum

Japan is an aging society. By 2050, the population is expected to be below 100 million, creating two main issues: a lack of labor force and a shrinking domestic market. As a company specializing in planetary gear reducers, to what extent must Japanese corporations and firms look overseas in order to ensure business success?

As a Japanese manufacturer, we must explore opportunities in foreign markets and persist in our efforts. While we can certainly maintain production in Japan, we believe that it's more reasonable to operate factories in overseas markets rather than bringing in additional foreign labor. From a political standpoint, this approach can help address some of the issues within Japan, such as labor shortages.

The scarcity of labor presents a significant challenge for our business. We are currently experiencing difficulties in hiring both factory operators and engineers for development and design.

With 27 years of experience in operating a factory in the Philippines and 19 years in China, we are well-positioned to leverage this expertise. Our goal is to not only strengthen our capabilities in design and development but also to enhance our marketing strategies in foreign markets. This strategic move will contribute to our continued growth as a company.

Are you looking to open new factories overseas in the coming years? If so, where would you be interested in continuing your international expansion? What strategies would you employ, would it be establishing M&A, new subsidiaries and factories or joint ventures?

We've done several business research projects, even in India, which I've visited three times. In February 2023, I had the opportunity to visit Texas, which is currently experiencing rapid economic growth, making it an appealing market. In fact, we will participate in ATX West Expo 2024 in order to expand business relations with customers in the USA.

Our approach has always focused on steady and measured growth, rather than taking significant risks for the sake of rapid expansion. Considering our current capability, I would say that establishing factories in India and the US may be too early for us.

Our international expansion strategy involves enhancing the capacity, especially for planetary gears of our existing facility in the Philippines. We are actively engaged in the research phase, with the goal of doubling or even tripling its current sales volume.

Did your production expansion in your factories in the Philippines and China help you reach and cater to new markets? How did you manage to maintain the same level of quality and standards as Japan in these locations?

Initially, we dispatched Japanese engineers to our factories in the Philippines and China to provide detailed training on quality control and the manufacturing process. However, we recognized the importance of enhancing the capabilities and knowledge of our local staff to efficiently manage these facilities. We couldn't rely on a constant stream of Japanese engineers overseeing local employees. Eventually, we made the strategic decision to delegate responsibility and authority to our local teams in both locations. This approach allowed them to have some authority in their development, although establishing this empowerment system in these countries was a significant challenge.

At present, our Chinese factory employs approximately 200 people, all of whom are non-Japanese. In the Philippines, we have around 650 employees, with just two being Japanese. Our focus has been on enhancing the skills and capabilities of our local workforce, coupled with providing competitive compensation to retain top talent. In comparison to our Japanese competitors, we have significantly reduced the presence of Japanese staff in these foreign factories. We firmly believe that entrusting responsibility to our local teams yields better results.

Our Japanese staff engage in daily web meetings with our local counterparts in the Philippines and China, a process facilitated by modern technology. While our Japanese factory is relatively small, we currently export reducers from this facility to foreign markets. Expanding the capacity of our Philippine factory will enable us to export products to the United States and European countries.

Considering the geopolitical instability and uncertainties in regions like the U.S., Europe, the Middle East, and Southeast Asia stands out for its relative stability, with fewer conflicts and minimal incidents of extreme terrorism. Social stability is a crucial factor for economic growth in any nation. Given this perspective, Southeast Asia appears to be the most promising region globally. We feel fortunate to have a factory in the Philippines as an operational site for further expansion in Southeast Asia, possibly through mergers and acquisitions. While we don't have specific plans yet, we aim to extend our production base and enhance our development & design, and marketing capabilities.

Matex Planetary Drive International,Inc.

Wuxi Matex Precision Co., Ltd.

There has been a rise of regional manufacturers over the last decade, such as China, South Korea, and Taiwan, which have duplicated the Japanese model at a cheaper cost and cheaper quality, pushing many Japanese companies to move to niche B2B fields. As a planetary gear reducer specialist, what would be the core strength of your company, Matex, to appeal to foreign clients?

I personally prefer to avoid engaging in price competition and merely offering cheaper products. I believe operating in a blue ocean rather than a red ocean is more strategic. To do this, we need to differentiate our business. In 1955, we possessed plastic injection molding technology, enabling us to produce gears that earned high recognition in the industry. We have entered into metal processing technology, a field we hadn't previously explored. Notably, most producers of planetary gear reducers typically begin with metal processing technology. However, we set ourselves apart by starting with plastic injection molding. In this context, our approach is distinct from that of our competitors.

If we solely focused on plastic injection molding and emphasized mass production, it would require substantial investments in facilities and machines, which could reduce overall profit margins. By using this specific injection molding technology to create gears, we have concentrated on establishing a solid industry reputation as a company specializing in mechanism components.

Our reputation has attracted customers to us, and I consider this a core strength. Moreover, our strong suit lies in our design and development capabilities. We can tailor gear solutions according to our customers' specific requirements. Unlike many reducer manufacturers who offer standardized product lines for customers to choose from, we provide customized design and development services. When we can efficiently mass-produce these customized products, the customers can absorb substantial customization or design fees. This level of service is highly satisfying for our customers.

Additionally, we have the capability to assemble products in-house, offering them as a complete unit or module. Unlike other manufacturers who produce reducers exclusively, we can manufacture modules including motors and controllers in conjunction with these devices. We create a unit or module of the device, enabling us to deliver an all-in-one service, from design to mass production. This comprehensive approach is akin to being a one-stop shop, providing services that customers greatly appreciate and recognize for their quality assurance.

Toschtec reducers are compact cycloidal reducers that you have designed for applications like small robots or service robots. What is the main focus of your R&D strategy? Are there any new products or recent developments that you can share with us today?

Currently, Toschtec is still in the prototype stage, and we haven't commercialized it yet. Our initial entry into the production of planetary gear reducers led us to explore cycloidal reducers, ultimately resulting in the development of the Toschtec reducer. However, to be frank, our Toschtec reducer deepened our understanding of reducers, and it paved the way for partner robots industry.

Reduction gears clockwise from top left (φ/Reduction Ratio): φ98/1:50、φ75/1:4、φ146/1:5 φ61.5/1:15.24、φ35/1:3.667

Our core expertise lies in producing cost-effective gear reducers with high resistance but at the expense of precision. We're committed to researching ways to enhance precision without driving up costs. Our ongoing research and development efforts are contributing toward creating more cost-efficient products.

Additionally, we're actively seeking partners in the United States and Europe for new collaborations.

At present, the development of our planetary gear reducers is exclusively carried out in Japan. However, we intend to nurture our engineers and designers in the Philippines. As we expand the capacity of our facility there, we aim to establish a development team and provide the necessary support for our staff to evolve into development specialists. They possess strong communication skills, enabling them to expand our business worldwide.

While we can't disclose specific details, we are actively collaborating with a major automotive manufacturer to design a reducer for the partner robots they are currently developing.

The challenge of a declining population isn't unique to Japan; it also affects other advanced countries. The United States and European nations are attempting to address this issue by encouraging immigration, but this approach comes with its own set of challenges. The consequence of this population shift is a labor shortage, particularly in manufacturing. In fact, an increasing number of individuals are reluctant to work in factories. For this reason, I'm emphasizing the development of partner robots designed to function within factory settings.

My long-standing ambition has been to enter the field of robotics, but it's a goal we can't achieve alone. It would be great if we could support that development with our technology and have robots working for us. While it's good to automate the factory process, we can also use robots capable of operating machinery and performing assembly tasks on behalf of human workers.

By doing so, we have the potential to grow the economy and enrich our country even in the face of a declining population. This is a personal dream of mine, and we eagerly anticipate actively contributing to this endeavor through our expertise in reducers and electric actuators. I firmly believe that there is immense potential in this field.

Japan leads the world in industrial robot production. Looking ahead, the demand for robots in both factory and household settings will continue to grow. It's possible that we'll see a service robot in nearly every household at some point. For the safety of humans, these robots must be lightweight to avoid the risk of injury from heavy machinery. This is where the use of plastic, as opposed to metal, becomes essential. We are collaborating with Sumitomo Heavy Industries to develop precision gears for robots with lightweight and high reduction ratios using plastic or resin. Therefore, our efforts are focused on creating lightweight, user-friendly, cost-effective, and mass-producible partner robot components.

I believe that our reducers will be needed, and for that purpose, we are working on this area with a lot of hope.

Our primary focus moving forward will remain on the automotive industry, particularly in the EV field, which is rapidly becoming the industry's mainstream. EVs now use more motors and reduction gears for smaller components to improve the comfort of cars than conventional vehicles. We believe that our reducers can find more opportunities in this context. We are actively working on marketing strategies for international markets and have even secured orders from a renowned European manufacturer of automobiles and motorcycles. The automotive sector's transition to EVs has increased reliance on motors, often accompanied by the need for reducers.

Regarding our expansion into the robotics field, we expect that this will happen in the future. Currently, our reducers aren't so expensive, and we cannot anticipate a significant surge in demand for robots at this moment. Our opportunity in the robotics industry will likely emerge as the demand volume for robots increases. Consequently, our focus for the next few years will remain on the automotive industry.

If we were to interview you all over again on the last day of your presidency, whenever that may be in the future, do you have a lasting legacy that you'd like to be known for? What would you like to be the defining qualities of your era as a president?

I am neither the founder of this company nor an executive in a large corporation. As the fifth-generation president, my primary mission is to ensure the long-term sustainability of our company. With over a century of history, my ultimate goal is to make this company even better before passing it on to the next generation, particularly to my son. My aim is not solely focused on generating significant profits for myself.

Many Japanese companies have endured for more than a century. The world's oldest company, Kongo Gumi in Osaka, has thrived for almost 1,500 years as a construction firm. However, it would be increasingly difficult for any company to survive long-term due to globalization.

In this context, I would like to pursue stable growth for our company by responding to various risks. We aspire to create stability for the well-being of our group employees and all stakeholders, including our overseas clients. My responsibility is to prepare this company, Matex, for the next 100 years, with the intent to pass it down to future generations.

I don't have any personal goal or ambition to become this company's legacy. Instead, my focus is on making this company better and ensuring its continued success.

0 COMMENTS