The utilisation of fluids and gases are key to many industrial manufacturing process, and so the need to measure their flow is critical to success. Enter Kofloc, specialists in providing flow meters for industries that require them. In this interview, president Nozomi Kojima explains the strengths of Kofloc and the company's goal of providing to the semiconductor industry.

Could you give us your opinion as to why Japan is so successful in high mix, low volume, niche business categories, and how are Japanese companies able to hold off competition from other regional players?

Since the 1990s, Japan’s competitiveness has been declining overall. Japan was originally strong in household electronic appliances, however these products were easily replicated by the emerging nations who took over the market. That left more complex products such as automotive devices, measuring devices and automated manufacturing machines & machine tools which are much harder to replicate so these products have remained in Japan.

Like many other Japanese companies, we are aiming to dominate a niche, and what this means is providing complex manufactured products, and not targeting the mass market. In Japan, it's more about pursuing quality for each specific product. It's important that our factory and workers are very committed to the monozukuri philosophy itself as well as the kaizen process of continual improvement so that we can constantly upgrade our products and increase our international competitiveness.

What was the impact of Covid on your company, and what new sales channels or changes did you make to react to the pandemic?

There have been many impacts of Covid on the way we run our business. Like many other companies, we have been engaged in online sales. Meetings which used to be face-to-face are now conducted remotely, and there are pros and cons to this. Of course, you can reduce a lot of budget by doing things online but at the same time by meeting face to face, you have the chitchat and through chitchat you learn a lot, so building a relationship is important to do face to face.

What we need to consider is having a hybrid type of sales, and that is the approach we're trying to take. In terms of product sales, we see an increase - despite the Covid situation - in terms of health care and medical items. For example, the mass flow controller that's used in the medical field, often for Covid treatment with ECMO (Extracorporeal Membrane Oxygenation) devices like automatic lungs and hearts, and also ventilators. Our product is widely used in all of these things.

As for our gas generators, we have an ozone generator which is widely used in hospitals, so along with semiconductors, medical has always been our target, and with Covid there's been an increase in terms of medical market demand.

In response to Japan’s aging population, to what extent has your company looked overseas for new customers, and what are you doing to ensure your business longevity in terms of recruitment?

Personally, I don't consider the population issue in Japan as a serious issue. I don't take it that negatively. We're trying to find a way to get through this situation by, of course, introducing more robotics and making work flows more efficient so that they require less manpower. In terms of sales, remote working and communication is also a good way of improving the efficiency of the business, so in the end I'm thinking and hoping that the situation will eventually allow us to focus more on the monozukuri side again, which is at our core and is the essence of our work.

To mitigate the impact of the shrinking market in Japan, we are looking overseas. Currently we have 25% of our sales coming from overseas markets. We are looking at shifting ourselves into overseas markets more, raising that figure to 30 or 40%, or even more. We already have a global presence and conduct activities worldwide, but since we're dependent on specific customers, there is a risk that when they discontinue making certain products they may stop using our products. Our overseas strategy is therefore to try and broaden the customer base in order to safeguard demand.

Your products are used to measure and control the flow of liquids. They’re split into four broad categories. Flow control meters, gas control meters, gas generating devices and engineering devices. Which one of these four divisions is your main focus and which brings in the most revenue?

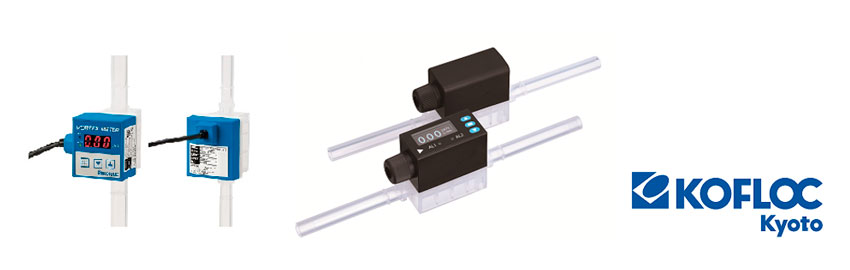

Our approach to creating products was to first target an industry and then look into what needs each individual industry might have, and provide accordingly. We divide our business divisions into two. One is the flow parts division which includes mass flow meters as well as flow controllers, and the other is gas generators, which is called the flow system division.

We are focused on all our products, targeting industries such as the semiconductor industry which has big demand for measurement devices as well as controllers. In terms of other industries such as medical, pharmaceutical and food, we provide controllers and measurement devices as well as gas generators.

In Japan we've seen Sony Semiconductor make a new foundry in Kumamoto. What opportunities does such regional revitalization present for your company?

I don't know if I can disclose this information, but to be very honest with you, our FCL200 liquid flow meter was used by Tokyo Electron about 10 years ago, but at that time, there were ups and downs in the semiconductor industry and we were not able to go along with the flow. Currently what we are trying to do is to go back to the semiconductor industry, and now there are no ups and downs – it is only going up now - so we are trying to re-enter the market with our flow meters. We’re not only focusing on Japanese companies of course. We’re looking into going overseas and doing a lot of research and development which would be applicable to the industry.

Our focus in terms of company strategy is not to go after the mass market, but rather to focus on a specific market so that we could provide specifically engineered products for each company. That entails a certain cost, so we are focused on producing products that could generate appropriate profits that are commensurate with the effort we put into our monozukuri. Our company credo says to put the customer first, so we will continue to focus on our customers’ needs and try to respond to specific needs using our technology and effort of monozukuri.

You’ve recently created a new outdoor gas generator. Why did you develop this product? What needs did you foresee it addressing, and what new markets would it allow you to tackle?

For our gas generator, which is part of our flow system division, we collaborated with a well-known compressor manufacturer to develop a new type of gas generator that could be placed outdoors. The reason why is because we were focused on factory air cleansing or generating nitrogen or oxygen, and if we were to place those units indoors, they would require quite a lot of footprint, and that was not feasible. By collaborating with Hokuetsu, we were able to create a packaged unit that combines the compressor and the gas generator. How this system works is that there is an active charcoal catalyst in the device that allows either nitrogen or oxygen to be separated as required. Pressure is needed for this process so that’s why there’s a compressor in the unit also.

We were able to develop and apply this product not only to the provision of gas to factories, but also to aquaculture, which was quite a surprise to us. Aquaculture requires oxygen and conventionally it was the oxygen tank that provided oxygen, but this new type of gas generator can support fish-farming activities on land and there's a boom in this industry so we hope for an uplift in sales as a result.

You have many products serving many different industries. Could you highlight for our readers a single product that best represents Kofloc?

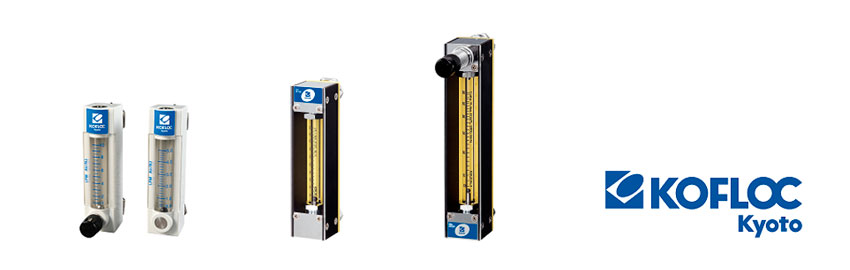

To name a representative product of Kofloc, it would have to be our original flow meter which is analog and mechanical and has had a long run of over 60 to 70 years.

Is collaboration something that you're looking to pursue, especially with foreign partners as you look to develop new products, and what type of partners are you looking for?

In terms of collaboration, we’re actively working with other companies on special technologies. We’re mainly focused on technical alliances. Of course, the ideal situation is to complete everything in house but that's not feasible, so collaborating with other companies to advance and expedite the monozukuri process is crucial. The companies we’re collaborating with on the upgrading of our flow controllers are all domestic Japanese companies. As for collaboration with foreign companies, we are partnering with an Italian company on product development and it would be nice to strengthen that alliance and have more companies working together in the development space.

On the production side, we have a factory in China and we provide production and maintenance services there. As a global trend, Japanese companies are trying to take back their manufacturing facilities to Japan with the rise of human labor costs, but we haven't actually tried operating actively in the global market in terms of production as well as sales. We want to reach out further and create a system which involves local manufacturing supplying local markets.

You mentioned that 40% would be the sales target in the future for your international business. Which countries or which regions do you think that will come from?

For semiconductors it's the East Asian region and for medical it’s the European countries that we target.

Let's say we come back to interview you again in 10-20 years' time. What would you like to tell us about your goals and dreams for the company in that timeframe, and what would you like to have achieved by then?

In the future I’d like our company to continue pursuing our company motto and taking a scientific approach towards fluid. There are many Kyoto companies with history and technology and we would like to continue being one of them, and represent Kyoto. We will be pursuing more markets that can use our specific instruments and technologies. The reason why we’ve been able to come this far with 70 years of history is that - as my predecessors have said - it's all about the people working at the company. Being a company that represents Kyoto, it's very important to keep our focus on the people who work in our company and it's important to create excitement and a good monozukuri process.

Reflecting back on myself as well as our experienced workers, we witnessed the Lehman Brothers shock and other economic periods of recession. We didn’t actually see many boom times like the ‘bubble generation’ who lived during a period of economic boom. As a manufacturer you can’t get this kind of success overnight or in the short term. It takes a three to five or even 10 years. It’s a long-term thing, so as president I want to create not only the products but the experiences that would excite the heart of the employees working at Kofloc.

0 COMMENTS