One of the world’s leading manufacturers of valves, KITZ Corporation’s purpose is to contribute to society, infrastructure and a prosperous global environment and sustainable future through the pursuit of fluid control technology and materials development.

What does monozukuri mean to KITZ, and what are the strengths or competitive advantages of your company that allow you to excel in the international market?

In 2021, KITZ celebrated its 70th anniversary, and I am the fifth-generation president. The founder’s philosophy has been passed down throughout the generations, and that is to value the materials, and perform integrated processing from beginning to end – total manufacturing. That is our main strength.

We have our own technology and facilities to do casting, whereas other valve companies usually purchase or delegate that work to a casting company. It's true that in China, India and other Asian countries there are many mass production companies that are growing as competitors, but we still have strength in terms of quality and the techniques we use in the casting itself.

In 2022 we revised our corporate philosophy, calling it the “KITZ Statement of Corporate Mission”, so it would be easier to understand the purpose and objective of our company’s existence, which is to contribute to society, infrastructure and a prosperous global environment and a sustainable future through the pursuit of fluid control technology and materials development.

We released our Long-term Management Vision, and Medium-term Management Plan, on February 10th this year. If we continue our business as usual, then we won't be able to maintain our growth, so we have revised and renewed our corporate philosophy as well as the slogan of the company in order to aim for - and achieve – a higher objective.

What challenges and opportunities do you see stemming from Japan’s unique demographic situation?

To keep our factories going, we have been welcoming foreign workers, especially in areas where the work is more streamlined. Usually in Japanese companies, the retirement age is 60 and if one is to continue working after that, their salary goes down. At our company they're welcome to stay longer if they want to. We provide a yearly contract and evaluate their efforts and outcomes regularly, and we try to ensure that their salary doesn’t fall below what it was previously.

In the past, we used to focus on new graduates from universities and graduate schools but now we have broadened our search to include specialized technical high schools and technical colleges. We send our human resources personnel to go and talk to the younger generations in high schools and technical colleges. Although the population is declining, there is still a certain percentage of young people interested in casting and processing.

Also, we are calling for diversity in our management, so we are actively hiring young women with mechanical backgrounds. In Japan it is very rare for a young woman to have more of an industrial or mechanical background, but we are trying to have a 50-50 split. If they show their talent we try to improve their treatment so they can be more active in the company.

In terms of digitalization, we are pursuing smart factories through DX, but there is a financial barrier to entry. If you purchase robots and automated machinery from other companies, it costs a few million Japanese yen. We’re very proud of the work of our staff, especially our younger engineers, who have purchased parts and assembled machinery by themselves. This way, it costs less than 1,000,000 yen to automate our production lines, so we are heavily dependent on the younger generation for these kinds of changes.

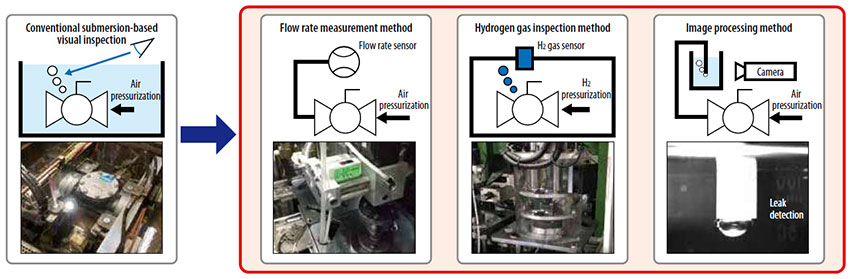

In the past, we used the human eye for inspection, but our younger generation made automated inspection machines. We used to use pneumatics or nitrogen for inspections, but now we have a hydrogen-based inspection machine. Other companies are actually asking to use our inspection technology.

Improving the leak inspection process through DX

How are you expanding your offering to better appeal to Japan’s adjacent semiconductor manufacturers, and what do you think makes Japan such a good ecosystem to support major players in this industry?

Globally speaking, there is high demand for Japanese products in the semiconductor field, because Japanese products are considered high quality. The semiconductor industry is always evolving and requires new technology, and Japanese firms, including ours, have the flexibility and adaptability to service the growing industry.

However, in order for us to accommodate these growing needs that will doubtless continue through 2030, we have established a new valve manufacturing factory dedicated to semiconductor manufacturing equipment so we can provide customers with the latest products as quickly as possible.

Actually, we have already received one year’s worth of orders, but since the price of materials is going up and we can't accurately foresee the future, I've been telling my staff to hold back from receiving new orders. Despite this, we still keep receiving more orders, but it’s very difficult to foresee how this growth will continue.

What kind of solutions are you providing to equipment manufacturers to help lower the environmental impact of their machines through your valves and fluid control technology?

Our valves are applied in the semiconductor industry both in the dry process and wet process. Our valves are used for fluid control and also in machine control, which involves using air or other pressure.

We're not only focusing on semiconductor manufacturing itself, but rather the whole industry of peripherals. For example, a data center has many servers and it dissipates heat, so it's necessary to use air conditioning (AC) in order to cool down the equipment. Many of our butterfly valves are used in those AC units.

With a large amount of water used by a typical semiconductor fab being ultra-purified water, and there are three major Japanese companies that manufacture the water purifiers, and they use a lot of our butterfly valves. Also globally, there are many manufacturers that make water treatment facilities, so we want to target those too.

Also, we have our filter business division, called KITZ Micro Filter, and this division is also doing very well to purify and maintain the cleanness of fluids. We’ve already decided that we'll have another factory dedicated to this type of filter.

The fine chemical field is another area of growing demand, and they require even cleaner valves. We are doing research and development so we can cater to the growing needs of fine chemical plants that are dedicated to semiconductors. The semiconductor industry is a massive industry and there are many approaches we can take, so this would certainly be a major part of the KITZ group’s sales from 2022 to 2024.

The longevity of valve products is very important, with PVC resins now being used by some makers to create corrosion resistant valves. What kind of steps are you taking in terms of R&D to ensure a long life cycle for your products?

At KITZ, we have long been focusing ourselves on metal based materials such as bronze, brass, cast iron, stainless steel and aluminum, but recently we have also been looking at plastics and continuing our research and development.

Of course, there is a slow shift from metal valves to plastic valves and we want to be proactive in changing ourselves to meet changing market needs. We have substantial knowledge within the metal field, and we have special technology to clean the surface of metal in order to increase its longevity, but we now also use PFA-type resins which give us a comprehensive approach when catering to the rise in demand for cleaner valves.

Digitalization is considered an essential element in improving energy efficiency in various environments. To what extent do you think digital transformation can transform fluid control systems?

In terms of valves, we are using DX in a system we have developed called the KITZ SMART MONITORING SYSTEM (KISMOS) which uses a sensor in a valve that monitors the flow and accumulates this data on a cloud server. We can then provide this information to our customers, and based on this data we can determine the appropriate time to make a replacement, or determine the nature of any abnormality. Basically, we can diagnose the valve using that data.

Recently, we have launched a new service-based business using DX to handle that data, and KISMOS is applicable not only to our valves but other companies’ valves as well. We want to use the KISMOS to make customers switch to using our valves.

Was this sensor and data technology produced in-house or did you work with a partner?

We have collaborated with our partnering company, particularly because plants are a potentially dangerous and volatile environment, so the sensor must be resistant to explosions. We have been engaged in many collaborations to achieve this high standard.

Is the digital cloud related sensing system catered to only the Japanese market or is it something that's been localized or tailored for your customers overseas?

We are currently focusing on the domestic market together with major chemical companies. Once we have enough substantial experience, we will want to go abroad.

You've been expanding since the 1980s in terms of manufacturing, sales locations and distribution networks all around the globe. Is there a particular market or region that you consider the most critical going forward?

Our company strategy is to focus on Japan plus three areas, which are the Americas, Europe, and ASEAN. Plus there are two more countries, which are China and India. Currently our focus is particularly the US, ASEAN and Chinese markets.

China, as you know, has been called the factory of global industry, and our company also has a few factories in China used for export to other countries. However, for geopolitical reasons, I've been giving instructions to change direction and place more emphasis on the Chinese domestic market by producing products that cater to the needs of Chinese companies.

As for ASEAN, I was in the area from 2017 to 2018. We have a factory in Thailand that does bronze and brass manufacturing. We also established a new R&D center there so we can effectively conduct business in the ASEAN region. Ideally, we would want to have another factory in ASEAN to avoid the risk of another shutdown in China like we had in Shanghai recently.

In the US we’ve had an established sales base since the 1980s. However, we don’t have local manufacturing or any research and development function in the US and are keen to. We have tried several M&As, but none of them worked out. In the future maybe we’ll have a capital partnership or an M&A that works so that we can have a stronger presence in the US as well.

Currently, we only have manufacturing facilities for the semiconductor business in China and Japan but there is a growing market in the US, Taiwan and Korea so we want to expand ourselves in order to cater to a wider range of companies in the semiconductor industry.

The past few years have seen some major disruptions in global and local logistics due to factors such as the war in Ukraine, China’s zero-covid policy and the rising price of oil. How have you been managing or mitigating these global logistics disruptions?

For our business continuity plan, we have shifted our manufacturing capacity and diversified our factories so that we can mitigate the impact of such disruption. However, during the Shanghai lock down our factory was out of business for one month. During that time we had to utilize Taiwanese and Japanese factories to make up for the Shanghai product deficit. The amount produced in Shanghai was so massive that we have not been able to catch up 100%, and we will continue to be impacted by this situation until the end of autumn or even the end of this year.

Also, the disruptions in logistics made it difficult for us to secure cargo ship and truck transportation. There have been delays in both forms of transport, and for example what was supposed to be delivered this month to our customers was delayed for a month so there is costly disruption for our customers. This has not returned to normal yet. Our European group company has acquired a project in China and they were delivering products through Russia by train but now that is suspended, so there are many impacts on our logistics.

Let's say we come back to interview you again in four years' time for your company’s 75th anniversary. What would you like to tell us about your goals and dreams for the company in that timeframe?

As the management of the company, I feel it is my mission to transform ourselves into a new KITZ group, which means transforming ourselves by expanding into new business areas and finding new ways to grow. For example, carbon neutrality is a hot topic, and in the automotive field there's been a discussion on which direction to go in terms of energy. Hydrogen will be key, so we will be developing the product and catering to this new energy source in the near future.

Our focus is to contribute to the sustainable growth of society through digitalization and the control of new energy sources. Of course, the company is operated by people so human resources are vital to maintaining a sustainable company. It is my mission to create a working environment which makes workers feel more comfortable, proud and satisfied to be working at KITZ. We need to continue to be chosen by society as well as be recognized by stakeholders for the sustainable management that we conduct as a company.

0 COMMENTS