Discover how IIX, a pioneer in the display industry, is revolutionizing the correction of unevenness in OLED displays while prioritizing sustainability. Through a unique blend of cutting-edge technology, meticulous craftsmanship, and a commitment to global harmony, IIX is not only shaping the future of display solutions but also paving the way for a more environmentally conscious industry.

If we could start with a short introduction to your company. What are IIX’s main competencies and what advantages do you believe you have that set you apart from your competition?

At its core, IIX is seeking to become a hidden champion; an indispensable, yet hidden entity within the display industry. First, I should explain our company name: IIX.

Our company motto is Infinite Harmony and Unity. The center of the symbol ∞, which represents Infinity, is made up of the letter X.

The X within our name represents a mathematical X which itself is an unpredictable numerical figure. It also represents the unpredictable yet infinite possibilities of human beings. Our logo represents the dynamic passion of our company, and the entire company name, IIX, comes from Latin and is pronounced “ICKS.”

Our company was established in 1999 and we will be celebrating our 25th anniversary this year. We have a consolidated staff of 200 employees and last year our turnover was JPY 2.8 billion. In Japan, we have our Osaka, Hiroshima, and Fukuoka branches, and in China, we have a subsidiary in Shenzhen. Our mission statement says that we must contribute to society through the provision of high-quality products and services while also uplifting the well-being of our employees. The core value of IIX pretty much comes down to Infinity Harmony and Unity.

In our business, it is rare to find a simple solution in the digital realm. Instead, we often encounter diverse and complex situations that require us to collaborate with customers, partners, and various stakeholders to find optimal solutions. This analog process to coordinate and align the collaboration with others is called "Suriawase" in Japanese, and it is an area where many Japanese companies excel as a global niche top.

Our vision is to become the best alignment (Suriawase)provider, being able to contribute to the growth of our clients.

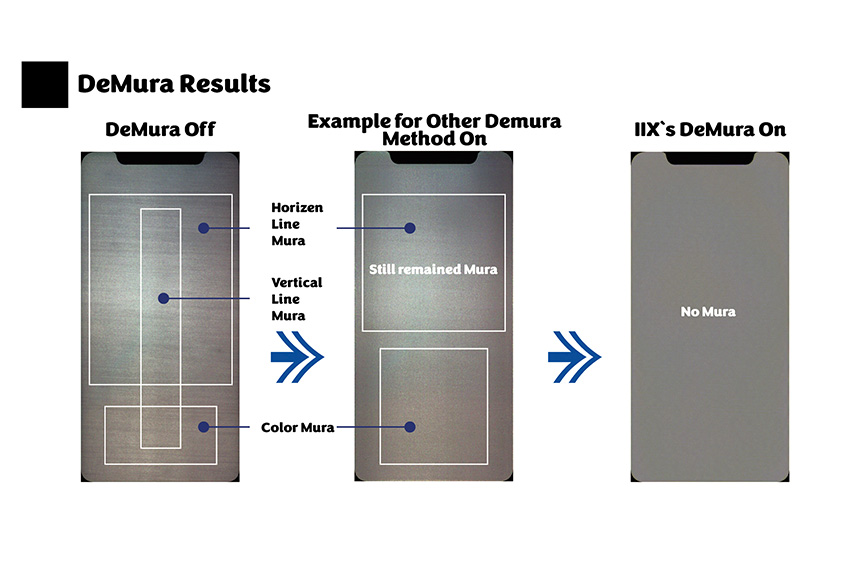

Next let me explain our main pillar business, our display solutions. What we provide is a service to correct unevenness in OLED (Organic Light Emitting Diode) displays. This unevenness is a very common defect that is seen in displays of, smartphones, and tablets. LED technology evolved in Japan so the word Mura, or unevenness, is commonly used. What happens in the panel is you see the lack of uniformity, and this defect happens either due to the manufacturing processes or the raw material. This unevenness is a significant factor in determining the quality of a display and manufacturers are very particular about rectifying these defects, but at the same time, it requires extra costs. I like to think of the process of fixing these defects as the same as washing dirty clothes in a washing machine.

Generic methods to fix unevenness (Mura) are rather standardized, and I like to think of it as using basic washing detergent in a standard washing machine. The big differentiating point of our company is our holistic approach, essentially making our company a professional laundry company in this analogy. We first analyze the root cause for the defect and then investigate the elements to provide the best alignment (Suriawase)solution for our clients.

We have world-class technology that allows us to tackle unevenness (Mura) that other companies cannot. We are one of the very few companies that can cater to AMOLED displays. Not only can we cater to current-generation displays, but also to next-generation display technologies such as mini-LED and micro-LED.

If unevenness (Mura) is not corrected the display will go to waste, so in this sense, we are contributing to sustainability. IIX provides holistic services with our patented technology on both the software and hardware sides, and this even extends to our De-Mura(to fix unevenness) IP that is embedded in the display driver IC. We started out having an extensive number of engineers, and now we have 40 engineers who specialize in hardware and software which gives us a distinct advantage.

Suriawase-DeMura engineering

In terms of De-Muring, software, and hardware play a significant role in analyzing the display solution and applying a solution that correctly compensates for irregularities. The software’s role is measurement and algorithm generation, while the hardware component is responsible for executing this algorithm and making real-time adjustments to displace output. What are some of the challenges involved in this process and how can you ensure accuracy?

First of all, we take an image of the unevenness(Mura) before analyzing the image displayed by the panel. Based on the results we then run our software which will carry out the correction process by taking data into the flash ROM where the unevenesses (Mura)are corrected by the IIX IP. This means that it isn’t just the algorithm that is pulling the weight, instead, it is a combination of many factors coming together to contribute to a holistic solution. The elements are the image-capturing device, the analysis tools, the software to generate the algorithm, and finally IIX IP.

What is interesting about unevenness (Mura) is that although a company’s manufacturing processes are standardized the unevenness (Mura)varies per manufacturing lot. An advantage we have is that we can intensively capture the unevenness (Mura)and analyze it comprehensively. This means that the compensation solution is at an optimal level.

Another advantage we have is that we have our business model. This model involved creating a De-Mura line beside the client’s production lines where our field application engineers (FAE) are dispatched. This enables services to be provided to clients on-site. Customers do not need to make initial investments because we provide a pay-as-you-go service.

For our overseas business, we are focusing on China where we are collaborating with big companies that have a huge affiliation with the Chinese market, and this is creating a synergistic effect. The outside environment is acting as a tailwind for us right now, since our major market is China and there is a huge uptick in Chinese domestic production, especially with OLED displays. There is a particular increase in demand for small/mid-scale OLED displays on things like PCs, and tablets. smartphones, and portable gaming handhelds. Additionally, there is a growing need for micro-LEDs for use in VR and AR glasses. Micro-LEDs in particular, while very high-quality, are also very susceptible to unevenness (Mura) issues, so we are predicting a significant increase in demand as these products continue to see further utilization. In Shenzhen, we conduct this De-Mura process in a clean room in our factory.

Lastly, let me touch upon our other businesses. We also have a shared systems business where we provide an engineering service for environmental controls of major buildings and data centers. By providing energy-saving solutions to the buildings we are giving maintenance to clients. With our fine polymer business that we recently started we are now providing a biodegradable resin for environmental purposes.

Over the past 25 years, Japan has seen the rise of regional manufacturing competitors who initially replicated the Japanese technologies at a cheaper labor cost. However, in recent years these competitors have built upon this foundation to create their world-leading technologies and take market share away from Japanese firms; a good case in point is the iPhone screen which for years was made by Japanese Display Companies but switched to Korean Display Companies with the introduction of OLED technology for the iPhone X. What is your take on how Japanese firms can continue to maintain global market shares despite the stiff regional price competition?

There is often an assumption that Japanese high-quality and high-pricing can be considered over-specification, and to some extent I do agree with this assumption. However, multiple Japanese companies are able to compete in the global market as a niche. There are commonalities among these companies, and that is that they all have their unique technologies or services. We aren’t talking about simple services either, we are talking about the amalgamation of technologies or services for systems, making them very sophisticated. Let’s take the field of chemical materials as an example.

Chemical materials such as protective films for polarizers and alignment film materials require close coordination and alignment (Suriawase) with display manufacturers and display manufacturing equipment manufacturers in addition to proprietary technology. Japanese manufacturers, known for their expertise in coordination and alignment(Suriawase), have a high market share worldwide. Japanese companies are able to provide special unique services that tend to specific needs.

The advantage of Japanese companies is that the ones that are competitive globally have the best alignment (Suriawase)technology or the ability to coordinate multiple aspects to create and consolidate into one new type of product or service. Basically, Japanese companies are providing things that no one can copy. Japanese companies have evolved to provide products and services that are very niche and not often visible or recognizable, yet very indispensable.

Our business mission roughly translates to “coordination and alignment (Suriawase).” What this means is the coordination of multiple technologies, ideas, and services together to provide something original.

In the post-COVID world we are seeing a diversification in supply chains, away from China and away from single-country risks, and with this change countries like India and Indonesia are emerging as new regional manufacturing hubs. We know that China is very important for your business model, but besides China, which other regions or countries do you see as important in the mid-term outlook for your business?

Displays are an essential component when it comes to human-digital interactions. No matter if it is hardware or software, there is always a display element to allow humans to control the equipment. Currently, the manufacturing of OLEDs is centered around China, but this new type of micro-LED is currently gaining relevance in Taiwan. It comes down to where the manufacturers feel is best to produce the displays. Wherever that is, there is always going to be demand for unevenness (Mura) correction. Wherever there is need we are happy to oblige.

We know that you have patented various display solutions in countries like Taiwan, Korea, the USA, China, and throughout the EU. Japanese companies are famous for their ability to develop new products which serve the ever-evolving needs of society and at 3% of annual GDP, Japan’s R&D spending is among the highest in the world with the US spending 2% and China just 1.5%. Can you tell us more about your R&D strategy? Are there any particular products you are working on that you would like to share with our readers?

Our R&D focuses on and follows the trends of display technology, for example, in the past LCD panels were a focus, and that led to mass production, and of course, as mass production is established prices go down. Manufacturers are then forced to develop new technologies to increase their profitability. This type of market trend is continuously happening

From LCDs to LEDs, from LEDs to OLEDs, and now we are heading into micro-LEDs and quantum dot displays (QLED). New technologies are always being developed and need to become more sophisticated, meaning there are more chances that defects occur during the production of these new panel types. Our business has us always at the forefront, understanding the latest types of panels in the market so that we can correct any unevenness (Mura) that might occur. Take OLEDs and micro-LEDs for example, they use completely different algorithms.

DeMura process offers the highest quality

Over the years, display technologies have evolved from traditional Cathode Ray Tube, then LCDs to today's sleek OLED displays. We saw recently, LG, introduced a breakthrough in transparent OLED displays and Samsung a 360° foldable panel for smartphones at CES 2024. What steps is IIX taking to ensure the compatibility of its solutions with emerging display technologies like transparent OLEDs and foldable screens?

First, it is important to understand the fundamental differences in each display type. For example, LCD displays are constructed with a backlight but in OLED displays, individual pixels illuminate with electricity. Obviously, the unevenness (Mura) that can occur in LCD panels is unique to LCDs, so understanding how unevenness (Mura) can occur in various panel types is vital. It allows our firm to find the correct solution for our clients depending on their needs.

In terms of developments, we complete everything in-house. For example, software development is done in-house, and if there is a specific request from a customer we act like a hospital; diagnosing the issue and developing a specific and unique solution tailored to the client's needs. This allows us to contain all of our technologies within, which means any partnerships we engage in are related to sales instead.

Japan's commitment to combating climate change has led to ambitious targets for carbon neutrality by 2050. This drive has prompted increased regulations and scrutiny, especially in sectors like construction and HVAC. A recent report from McKinsey reveals that AI-driven technologies can help businesses reduce their CO2 emissions by up to 10% and save costs by 20% powered by technologies like smart HVAC controls and sensors. As a company that is also involved in this industry through inspection and maintenance of AC control systems, what opportunities and challenges does IIX foresee regarding this?

When it comes to our building management business this theme of coordination (Suriawase) comes into play. We are acting as a system integrator of HVAC systems for buildings such as data centers. Large companies that provide cloud services have data centers all across Japan, and within these buildings, there is a critical requirement for strict temperature controls to maintain operability. Without this temperature control the servers may fail.

The advantage we have in this field is that we partner with almost all existing major air conditioning companies in the US and Japan. We don’t pertain to a specific manufacturer so we can provide any solution from any company to create the optimal combination for both energy savings and the best HVAC solution needed for the environment.

Our company has a large number of nationally qualified professionals necessary for this business field, and we actively invest in human capital by supporting employees in obtaining qualifications and improving their skills through generous certification allowances and other means.

Many companies in the construction industry have yet to fully embrace digitalization, but our company will be implementing DX Tool adoption starting this year and working towards improving operational productivity through Digital Power.

Interestingly, you went from video decoding initially to building control management, very different businesses. How did that idea come about?

The common philosophy we have in our company is coordination and alignment (Suriawase). This act of coordination is very analog and a human's ability to coordinate with others is a very important social skill to develop. Know-how plays a vital role in being able to provide optimal solutions and tracing back, all of these businesses have been originally done by different companies, we simply combined them all into one commonality, basically acting as the coordinator.

In terms of diversification, you are also involved in biodegradable plastics as well. Moving forward, are you looking into further diversifications or are you going to stick with your current portfolio of businesses?

Our biodegradable plastic business only started a few years ago so it hasn’t reached a substantial business scale quite yet. The purpose is to contribute to sustainability through the provision of biodegradable plastics. What differentiates our products is their durability and heat resistance when compared to other biodegradable plastics in the market. There is a particular focus on the food industry and the hotel industry, two industries that use a lot of plastic in products such as hangers and cutlery.

Eco-friendly biodegradable resins

Imagine that we come back and interview your company again in 2029. What goals or dreams would you like to achieve by the time we come back for that new interview?

Currently, we have three main pillars of our business, but you could say that none of them are that thick quite yet. We need to continue to develop all the pillars of our business so that one day we can have sturdy pillars that can support our company for many decades to come.

In terms of the unevenness (De-Mura) business, the display market is constantly growing at a rapid pace. In that sense, it is important for us to keep up with the latest trends and provide our services to cutting-edge technology providers.

With our building management systems, this is a business that we are looking to expand overseas. In Asia in particular we are actively recruiting foreign employees so we can increase our portfolio of international clients.

In regards to our plastic business, it is still hard to predict it, but we would like to continually keep this mindset towards contributing to sustainability. This is all in pursuit of reaching a turnover beyond JPY 10 billion by the year 2030.

Finally, I have a key message today that I would like to convey. The De-mura business is an environmentally friendly business process. We are essentially saving displays that would otherwise be discarded. On top of that, we run other environmentally friendly businesses, and this is in the pursuit of making IIX a company that contributes to global sustainability. With our main pillar business, we want to branch out further and diversify our portfolio, with the main goal being an initial public offering (IPO) in the near future.

0 COMMENTS