As a pioneer in ultrasonic technology, Honda Electronics is looking to support international markets with its unique products.

Over the last 25-30 years, Japan has seen the rise of regional manufacturing competitors who have replicated the Japanese monozukuri process but doing so at a cheaper labor cost, pushing Japan out of mass industrial markets. However, we still see that many Japanese firms are leaders when it comes to niche B2B fields. How have Japanese firms been able to maintain this leadership despite the stiff price competition?

Most Japanese companies would not simply expand to areas with stiff price competition, like Southeast Asia. It would be easy to assume that they would lose the stiff price competition war. The majority of Japanese companies are not willing to enter countries with cheaper labor costs that can lower the prices of their products. It is not their strategy to do so. Many Japanese firms have been facing difficulties when the currency rates fluctuate, which greatly affects their international trade. They have learned their lesson from that. Most companies in Japan take things seriously and try to focus on maximizing their capabilities before exporting to overseas countries. Their primary principle is to stabilize their cash flow status before taking the serious step of going overseas and maybe localizing their production there.

Due to this, the greater part of Japanese companies is focusing on niche B2B fields, which adopt only Japanese technologies, techniques and know-how. We lose in the price competition against similar products produced in countries with a cheaper labor force. Nevertheless, there are many things that Japanese companies can still improve on concerning overseas expansion. There are advantages and disadvantages when Japanese companies are trying to promote themselves overseas. Many Japanese firms focus on more than one idea. They think about where else their products and technologies can be applied. Some companies in Japan are now trying to employ various ways to promote themselves and find other applications which can take their business to the next level.

Another strong point that helps some Japanese companies remain leaders is the smaller boundaries imposed between the senior management and lower-rank staff. Everybody who works for a company in Japan is considered to be a part of one family, creating a good bond between individuals. This kind of good human relationship and corporate working environment can benefit most Japanese companies.

In comparison with some foreign companies, the Toyota Production System displays the art of kaizen philosophy. Most Japanese business enterprises go the extra mile and try to take the business to a new scale by employing kaizen, making continuous improvements every day, even with the small parts of the business to achieve greater results. A combination of the managerial aspect, Toyota Production System and other small ideas can create improved and beneficial results. In the end, the business is better than before.

Honda Electronics is specialized as a manufacturer of ultrasonic products. You developed the world's first transistorized portable fish finder in 1956 and your firm has since continued to be a pioneer in this technological field. Can you provide a brief overview of your expertise in ultrasonic technology and the role it plays in modern society today?

It is hard to explain briefly because ultrasonics and its usages have been broadening. When we developed this portable fish finder, the need existed just in the marine industry. Over time, several clients and needs from various kinds of industries have emerged. Our company is trying to evolve within these industries as well as the progressing needs and requests of different enterprises which we never could have imagined 50 years ago.

One example is the semiconductor industry, and our ultrasonic technologies are widely used in their fabrication process. Our company has to always look ahead to areas where our ultrasonic products could be used in their advanced developments. Of course, the fish finder is a part of our business, which was a popular product back in the day, and it has been praised by many who use it for professional and leisure applications. Currently, we see so many surprising requests from other industries we had never expected. In our many years of existence, we are continuing to focus only on ultrasonic technologies. The technologies are evolving, and many companies come to us with new needs and requests. Since we have been accumulating ultrasonic technologies for many years, we are in a good position. Ultrasonic technology can correspond to various kinds of needs to fit the times, such as measuring, cleaning, cutting, binding, and mixing.

Compared to radio waves and optics, the business of the ultrasonic industry still takes up a small share of the market. On that note, its potential applications are numerous. Again, the possibilities for ultrasonic technologies can be found in our daily lives and many industries. We are looking optimistically toward the future and discovering new areas where ultrasonic technologies can be applied.

We are differentiating our company from other firms that are related to ultrasonic production. Whenever we are looking at other related companies, we consider them occasionally as our clients, our rivals or competitors. At least in Japan, there is simply no competition in the field of ultrasonic. Therefore, our company's strong point is being capable to do everything in-house from the procurement of materials to the final product implementation. Some companies are only doing just a part of the business, such as making raw materials or manufacturing equipment. We are positioning ourselves as a technology-based company that creates this kind of weapon to be able to penetrate every industry where ultrasonic technology can be potentially utilized. Our present and future stand firmly on academic and cross-industry exchanges. We are a technology-based company, but we also create a new market that no other companies can enter.

Due to COVID, there have been major semiconductor chip shortages worldwide, resulting in many regional leaders pushing to increase their domestic production capacity. We also know that ultrasonic technology plays a crucial role in the cleaning of wafers during the manufacturing process. What opportunities do these regional firms present for Honda Electronics? How do you plan on taking advantage of them?

We have also experienced shortages of semiconductors for our products while manufacturing. Although the overall trend in the semiconductor industry is going toward smaller size and ultrafine processes, which invest in the manufacturing of advanced components, the supply of components used for our products has not yet progressed. On the other hand, requests from companies involved in the semiconductor manufacturing sector and related industries are increasing. While shifting technological elements to smaller sizes and ultrafine processes of semiconductors, the trend of going toward greater precision and higher accuracy is expected, and future expansion is expected in the fields where ultrasonic cleaning and piezoelectric sensors have not been used in the past. There are possibilities to generate new potential needs. We are also watching and preparing for day-to-day changes in product design, such as the miniaturization of battery size. Our technology can be used in areas other than semiconductor manufacturing, and we can see potential in all of those areas. We have the best ultrasonic technology and application know-how to fit these expectations.

Are there any industries or applications you are focusing on right now?

The major industry we are focusing on is the medical sector. Ultrasonic technologies are widely used in diagnostic imaging equipment, and several firms dominate in this market, such as GE and Philips in the US and Europe. Hence, it is difficult for an SME company like Honda Electronics to position itself in the market because there are already key players in this field with ultrasound and imaging diagnosis equipment. Nevertheless, we found a niche field in the domestic market, which is orthopedic, general medicine like inspection with needle puncture using ultrasound diagnosis equipment in humans. Our products can also be used for ultrasound diagnostic equipment for animal pregnancy and breeding for cattle, equine and camels. In some Islamic countries, medical screening and diagnosis have to be done for camels used in racing, so we provide our ultrasound imaging equipment for the diagnosis. Some of our sales staff have experienced camel racing to check their conditions. When I was in Germany, I checked the legs of horses before the race using ultrasound imaging equipment.

We are seeing developing economies in Southeast Asia as well as China and India, who are improving their healthcare systems every year, and as such, they are requiring the need for high-quality ultrasound technologies. Are you looking to export your ultrasound technologies to these developing economies?

We are looking at other nations, particularly the economically developing Southeast Asian countries such as Vietnam and Indonesia. We see the needs emerging from these countries because of their growing economies. Our fish finders can be used in these nations due to their evolving marine industry. We are looking to introduce, produce and export our ultrasonic products and techniques to other countries. Since it is difficult to do that on our own, we need to have a reliable partner to promote our products in any country. A reliable distributor would not only need to create sales proposals for our products and techniques but also solutions for maintenance or design. We expect our distributors not only to resell our products but also to provide extra services.

Ninety percent of the production we do in our company relies on others, including the production of our equipment under our own brand name, Honda Electronics. Big corporations like Toyota, Honda, Suzuki and Yamaha have been blessed by many companies located in Aichi prefecture that supply components to them. These companies have manufacturing capabilities that can serve us which is a big advantage for us. We are in charge of a smaller part of the whole business but manufacturing of the sensor is a very core technology. Although we are positioned as a manufacturing company, we are more of a technical-oriented company that opens brand-new markets through our technical capabilities. Having a chain of reliable partners with no capital relation, we rely on other companies' manufacturing capabilities to introduce and take our products to other industries.

Throughout our long journey, there have been ups and downs. It was on a Black Monday in the 1980s when the financial market collapsed and dragged down many industries. At the time, 70% of our fish finder production was exported to the US market. In a glimpse, we saw a huge downfall in everything we started to build in the US. It was a very bad time for the company, but we also learned. We focused on the things we can do and provide for our customers and expand our business to a variety of industries. Despite the ups and downs, we must stand and take on the challenges as part of our philosophy as an enterprise. We want to keep challenging ourselves no matter what the odds are.

It is important to have industry-academia relationships, so we are working hand in hand with a local university, for instance, Toyohashi University of Technology in Aichi prefecture for our R&D initiatives. We also have a Nagano office with Shinshu University, and we will soon work with Shizuoka University, which works in the agricultural field. There are many things that we are trying to do through our R&D activities because it is vital to prioritize what we do here. We truly believe that our company is based on technological know-how.

The evolution of ultrasonic technologies is important for the foundation of our company. It is difficult to find success with only the fish finder’s business. Due to the economic crisis, like Black Monday, we cannot rely on just one business. Since human resources are limited, that was the reason why we switched to outsourcing rather than doing things ourselves. We have to improve and go into many fields through academia, research documents, and cooperating with teachers, PhD holders and researchers. We are proclaiming that we are a technology-advanced company possessing ultrasonic techniques. In some ways, cooperating with industry academia is based on pro bono activity, since we do not have the capital or receive any kind of benefits. Nevertheless, our relationship mutually benefits both sides because we can both study together and find a pleasant outcome from such cooperation.

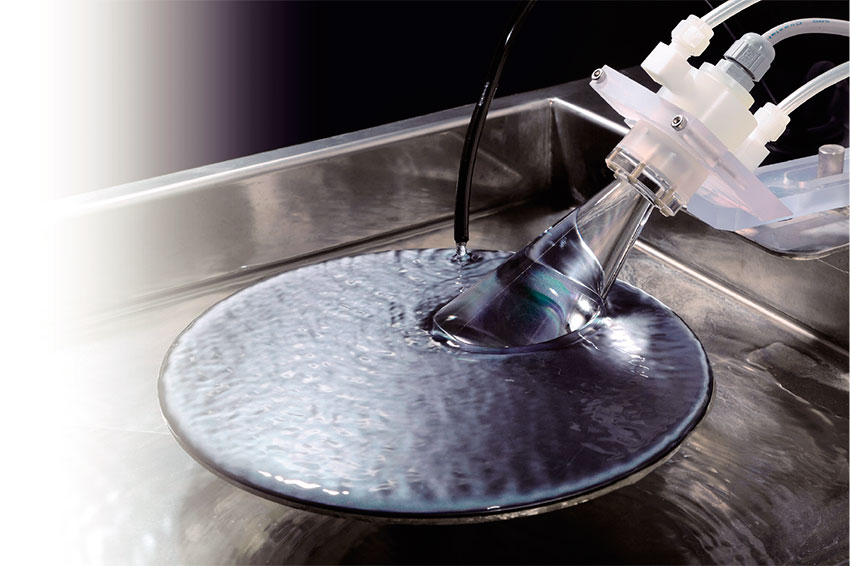

The WDX Series is an ultrasonic cleaner that utilizes your unique Dyna-Shock Modulation method. It is a method that connects the power ratio of ultrasonic waves that generates two frequencies simultaneously from the same transducer while also keeping the total output power constant. How is the DM method superior to more conventional ones? What applications does it allow you to unlock within your products?

The ultrasonic performance comes from the sensitivity of the workpiece material that you are cleaning. It is like washing your hands in the sink. If you are using too much soap, it can cause scratches or skin irritation. Likewise, too many ultrasonic waves can eventually cause damage to the workpiece material you are dealing with. On the other hand, not having enough ultrasonic waves will not reach the expected level. The Dyna-Shock Modulation method controls the power of ultrasonic waves, not allowing them to go up or go down too much. We have developed a transducer that can generate two different frequencies simultaneously. Because it provides damage-less cleaning of high frequency and strong cleaning of low frequency, this method is helpful in many ways to our clients in stabilizing the cleaning performance.

Imagine we come back in three years for your 70th anniversary as a company. What goals would you like to have accomplished by then?

We will be working on a five-year midterm action plan, which highlights our focus on overseas markets. Our division managers are going to be responsible for developing the overseas market. We are prioritizing our overseas activities more than the domestic market. The fish finder’s market for leisure applications in Japan is mature, and there is much less that we can do because there are already many loyal customers here. We are looking at promoting our fish finders to other countries, which is a part of our business. There are so many potential applications such as industrial use, cleaning and measurement of the flow rate of chemicals or liquids in the semiconductors production line.

In our overseas expansion, we are looking at economically developing countries in Southeast Asia. They are more attractive for us since we expect more ultrasonic needs coming from those markets. Although we are not sure about the form of partnerships we will later pursue, we know that we will need reliable partners and connections that can work with us in promoting our ultrasonic business overseas as well as providing maintenance of the products and technical services. We have backed up R&D activities with a lot of support from academic society, which gives us the foundation to deploy our deep knowledge of niche ultrasonic technology to the place where we can find partnerships in any industry. As company president, I would like to pay attention to our fiscal business results to reach new heights in sales. Being a benefit-able company is most important, but it also has to be based on a solid foundation of academic R&D initiatives in Japan, and taking these professional technologies to places we have never been. New market development is very vital for us at this point.

Interview conducted by Karune Walker & Sasha Lauture

0 COMMENTS