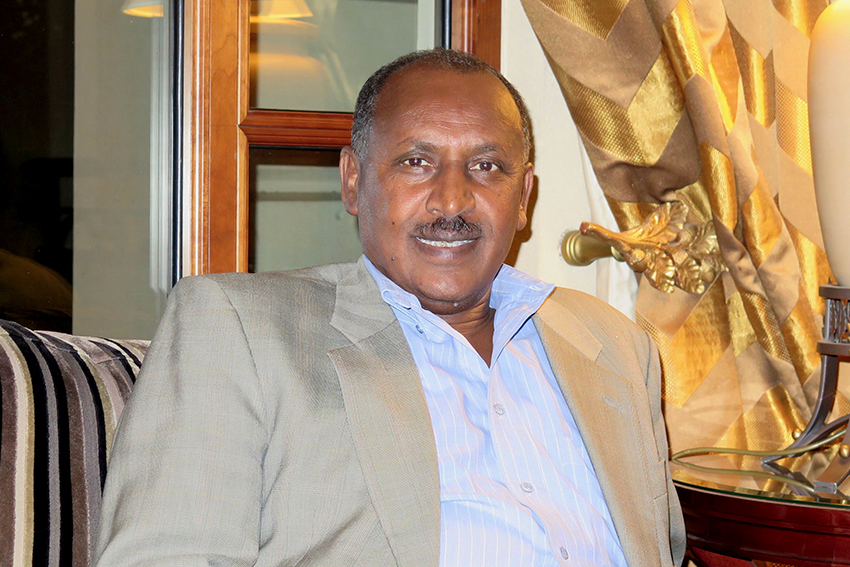

Ethiopia’s highly productive textile and garment manufacturing industry is recognized internationally for its quality, value, and environmental respect. Fassil Taddesse, CEO of Kebire Enterprises and President of the Ethiopian Textile and Garment Manufacturers Association, explains the industry’s competitive advantages and his vision of where it is heading.

As President of the Ethiopia Textile and Garment Association, what are the opportunities and the advantages regarding investment in the sector?

First and foremost, Ethiopia has an adequate amount of land for cotton cultivation. We have enough land to produce cotton in a size equal to Pakistan, which is the fourth producer in the world. Secondly, with a population of 94 million, we have an abundant trainable young productive force with a reasonable labor cost. For instance, for my factory in Mekelle, I brought a competent teacher from Sri Lanka to train my workers. Now my workers are well trained and highly motivated. We partner with H&M and NJ and our products are marketed in the US, the UK and Europe in the same style as Bangladesh. And yet, with less manpower and fewer machines, we produce 20% more than Bangladesh.

Moreover, electricity is cheap in our country, at a cost of only 3 US cents per kilowatt. Land lease is cheap as well, at a cost of 3 US cents per square meter per year for 60 years. Coupled with a stable and committed government, Ethiopia is certainly a favorable destination for foreign investors and partners.

What would you say to potential investors coming to the country regarding the textile and garment sector and investment laws?

Our investment laws are constantly improving. In the last five years, the investment laws have changed three times. Our knowledge about the industry is limited. We are mere infants. Not only in investment, but also in the banking sector and custom rules, we are always updating the framework. When we get exposure, we immediately change.

For instance, we faced some challenges in logistics. What the government did was reduce 25% of inland transport. Now, with the railway construction and the vessels coming from Asia to Ethiopian Shipping Lines, a discussion was necessary. In the meeting, our association was very vibrant and the government was very transparent. Now, Ethiopian Shipping Lines has plans to make a tremendous discount on the vessels coming from Asia. The government is open to change.

The textile and garment sector is working towards being a sustainable and environmentally friendly industry. How are you following the government’s strategy to be carbon neutral?

The government is building green industrial parks with zero discharge. There is no compromising with the environment. The Hawassa industrial park is finalized. Building parks in Mekelle, Kombolcha and Adama starts in March and it will only take nine months.

The person responsible for the railway, the industrial parks, the roads, Ethiopian Airlines, is a very vibrant person. He is the former Mayor of Addis Ababa and the city’s latest developments are his legacy. He is in charge of the industrial parks. He said he would finish the park in Hawassa green and with zero discharge in one year. He finished it. Now Mekelle and Kombolcha are following.

Our first experience with industrial parks was Central Bole Lemi, which focused on the textile and garment industry. Sometimes we rush into things without sufficient prior knowledge. But we learned significantly and what we learned in Bole Lemi is evident in Hawassa. Bole Lemi is a World Bank project and it took four years. The industrial park in Hawassa was finished in a year and will start production in June.

After Mekelle and Kombolcha, we are planning to establish other textile and garment, as well as leather, industrial parks in Adama, Dire Dawa, Bahir Dar and Jimma. All these parks are wholly environmentally friendly and could be good models for similar ventures in other countries.

In addition to the above parks, at present, there are four agricultural park locations, such as Sidama in the South, Bure in Afar Region, Batu in Amhara Region and Humera in Tigray Region, to speed up the industrialization process. These are the first agro-business parks bringing massive farmers together.

Kebire Enterprises is vertically integrated company beginning from the farm and all the way to the final product. What would you say are the competitive advantages of vertical integration?

Most West African countries, like Côte d’Ivoire, Mali and at present Uganda, are selling top quality cotton. In my enterprise, $1.60 cotton can be processed to a $15.50 garment. The production process is an opportunity for massive employment and the country benefits tenfold. The enterprise benefits from sales margins as well. The textile business is very competitive. Hence, the government is promoting value-addition.

Your export share on total year production is about 70%. What are your biggest markets and what other international expansion plans do you have?

Our major markets are Europe and the USA. Africa is a very lucrative market, but Ethiopia’s spillover effect is making only a slight difference. Good governance and government commitment of other African countries is a major prerequisite for regional trade. Hence, although there’s a huge potential, we haven’t extended our market in Africa. Nevertheless, we are planning to extend our markets to Canada and Australia.

What would you highlight as milestones achieved in your 15 years of existence?

Our 2013 vision was to be the best factory in East Africa, and that was accomplished. By 2017, we want to be the most preferred factory in Africa and we are on the right track. Two of our managers are heading to Las Vegas. We feel we are successful and the young Ethiopian people are leading it.

What would you say was the key to the achievement of 2013 vision and what would be the key to accomplishing your vision for 2017?

We prioritize human resource development. We worked with different developmental partners from Germany and the UK in capacity building, and our success is evident in our production capability. Six to seven years ago, we were producing 20,000 pieces per month. Currently, we are producing the same amount per day. Besides, our development partners played a great role in linking us to the right markets and credit network.

Furthermore, our market approach and attitude is customer oriented. We work closely with our customers with an eye on their preferences. Our participation in trade fairs and conferences has contributed to our knowledge base and expanding our network. Our own leadership schemes coupled with our well-coordinated and result-oriented planning made a huge impact as well. These are the keys to our market growth.

You are working with Primark, Tesco and George from the UK, and according to the figures in 2013 the UK accounted for 10% of exports. How important is the UK market to Kebire nowadays?

We do have reservations in mentioning who we are working with; as in some cases it’s not yet full scale. But we are focusing on the UK and Germany as part of Europe and as well in the US. We are a registered supplier of H&M.

What has been your greatest challenge leading your company and the industry and how did you overcome it?

Ever since I graduated, I was active in various industrial sectors. Educated in both natural and social sciences, I worked in finance, management, and business administration, and not to mention chemistry. I have been also active in government sectors such as public enterprise restructuring. Additionally, I partook in business development with Coca-Cola Africa in Ethiopia and Eritrea. I also worked on power projects, and my journey finally brought me to the textile and garment industry. And this is where I met my greatest challenge.

There is a Chinese saying, “One who is successful in the garment industry or farming in rocky mountains, needs to be taken to the Polite Bureau of Communist Party for he has done it all.” That is how challenging the garment industry is. It is analogous to an assembly. Every link in the system is interconnected and a glitch somewhere can paralyze the whole system. The industry is labor intensive, 90% to be exact, and as opposed to machines, humans are prone to mistakes. That is the challenge. Hence, it needs thorough knowledge of the sector and not to mention strong leadership. Although it took so much of my family time and leisure, in the end, it is rewarding. I am proud of my government as well for reaching this stage. It is like my family.

Which concepts would you like the international community to associate with textiles and garments produced in Ethiopia?

I would like to see more EKO-Tex certified Ethiopian textiles and garments in the international markets. We already have an excellent industrial culture and our cotton is organic. For instance, my garment is EKO-Tex certified, ISO certified, BSI, organic as well as WRAP certified. Not only as products for customers, but also the factory is EKO-Tex certified. Thus, I would like Ethiopian products to be known for their best quality, internationally standardized and certified.

Could you please discuss the prominence the African continent is gaining in the international arena?

Africa has abundant resources in terms of fertile land and a trainable youth. The economic constraints can be remedied through the process of industrial development. In this regard, the governments of each African state play a significant role in establishing a conducive environment for business and the infrastructural development it entails.

On the other hand, Africa needs support from the international community in such ventures as infrastructural development and investment. President Obama’s initiative in the energy/power sector is a suitable example. Instead of foreign aid, developmental partnerships in investment and infrastructural advancement contribute to stabilizing Africa. And stabilizing Africa is stabilizing the world.

Considering the hydropower dams and the Ethio-Djibouti Railway, it could be argued that we are currently facing the most ambitious infrastructural development in the history of Ethiopia. In an interview two years ago, you mentioned that the major challenge for the industry was the infrastructural accessibility to all markets. What is your impact assessment in this regard, particularly in the textile and garment industry?

First of all, Africa’s economy has been based on agriculture. Now is the right time for industrialization. And the textile and garment sector is the cornerstone of industrialization. Not only that, this sector has the longest value chain, which highly contributes to mass employment. But it can also be a means to win hard currency. Hard currency is needed for purchasing advanced technology and building infrastructure. Additionally, the byproducts from the textile and garment industry can be inputs for the oil industry and animal farming.

For such multifaceted agro-industries like textiles and garments, infrastructure is crucial. That is why currently 60% of the investment in Ethiopia is in infrastructure. Major steps are being taken not only in hydropower, but also in green energies like wind energy and solar energy. The railways run from Mekelle through Kombolcha to Djibouti, also connecting Adama, Hawassa and Bahir Dar. In addition to that, priority is given to human resource development in terms of skill development and health. Currently we have 34 universities throughout the country, as opposed to just two 20 years ago, and life expectancy is rising.

We are on the right track. There is cooperation and coordination between private and public sectors. Development partners like UK are working in line with our priorities. And most importantly we have a strong, stable and visionary government.

0 COMMENTS