A Japanese manufacturer founded in 1957, FEC specializes in world-class, high-strength chains, as well as supplying premium-quality automobile parts.

Could you give us a quick introduction to your company? What are your main competencies and what advantages allow your company to stand out among your competition?

Our company is called FEC Chain Corporation, so let me begin by explaining to you how our name came to be. In 1957 our company was established by Toyota Motor Sales. Our company was established as part of Toyota’s sales group by Mr. Shotaro Kamiya who envisioned future growth in the automotive market where snow chains would be in demand. Mr. Shotaro Kamiya was known as the “God of Sales” of Toyota, laying the foundation of the sales network utilized by Toyota to this day. He thought that Japan needed to nationalize the production of snow chains to evolve the automotive industry and established our company.

At first, our company was called “Toyo Seisa Co., Ltd.” before being changed to “Kyokuto Seisa Co., Ltd.”, which means “Far East Chain”. This change occurred in 1958. In 1981 we started the provision of automotive parts, especially various types of jacks. The reason we diversified into jacks and jack handles is that when we equip snow chains, a jack is required. In 1999 we further expanded into functional parts to stop the opening and closing of doors that we refer to as door checks.

It was in 2000 that we started receiving investments from Chuo Spring. Since 2004 we have also sold non-metallic snow chains and in 2021 we started the production of seat adjustment parts. This brings us to 2024 and the company we are today.

Our company specializes in two main chain products, such as industrial chain / electric hoist chain and other chain. These products carry heavy weights, so strength and durability are required. An example might be in pickup trucks where there is a chain that is used to carry the spare tire, something that we deliver to car manufacturers along with door checks, seat parts, and jacks.

In terms of sales amount, snow chain sales are unstable, influenced by the snowfall of the year. Ten years ago, our sales ratio was around 30% each for snow chains, industrial chains, and automobile parts. But in 2020 we transferred the sales of our snow chain to a group subsidiary company so the ratio of snow chain sales for us has dropped considerably. What remains in our company are genuine products for companies like Toyota and Nissan. So, we have increased our sales of automotive parts to strengthen the company’s business foundation while putting effort into industrial chains.

Right now is a pivotal time for Japanese makers. Policies like the US Inflation Reduction Act are forcing corporations to diversify their supply chains for reliability and to reduce country risks, with nations such as China. Japan is known for its reliability, advanced technology, and a weak JPY, so for the time being Japan has never been a more cost-effective option. This means that Japanese firms have an opportunity to expand their existing global market shares. Do you agree with this sentiment, and in your opinion, what do you believe to be the advantages of Japanese companies in this current macroeconomic environment?

It is true that there is a positive impact on our company due to the weak JPY, but this is only temporary and only for exports. Sales activities of Chinese and Korean competitors are also taking advantage of these conditions. So, we are focusing on adding high value with high quality and innovation to meet the needs of customers.

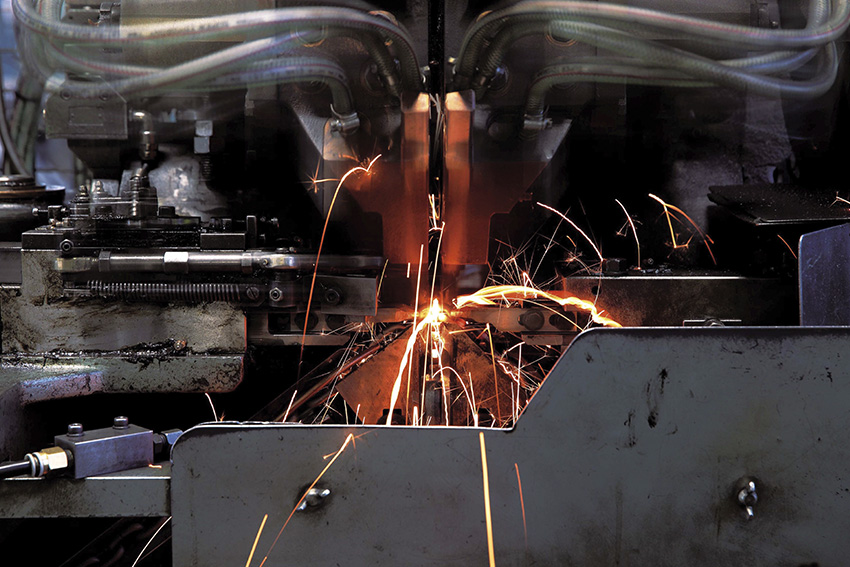

We believe that the reason why customers from all over the world choose our chains is that our stable quality and reliability are highly evaluated. For example, we can provide in-house integrated processing, which starts from procuring high-quality materials through bending and welding processes, through to the heating process and our products are known for their especially high quality. We have advantages not only in chain shape, which meets strict international industrial standards as well as Japanese ones but also we can also fit sprockets and various mating parts. We are making efforts to add more value to the products we provide through continuous research and development.

One area in which we have expertise is HydroFree galvanizing method which is able to process continuous galvanizing and is more cost effective when compared with electroless nickel plating. Although electroless nickel plating has high demand from customers, this method has the downside that it can only process a certain length of chain. On the contrary HydroFree can process galvanizing continuously with stable quality. Therefore, HydroFree enables a much longer length of chain which would be used for the maintenance hoist of windmill power generation.

HydroFree is our patented technology, and we want to continuously evolve and innovate in this area, making sure that our company is at the forefront of the industry. It might not seem flashy, but daily practice is the key to realizing this high quality. Kaizen and the principle of continuous improvement is certainly something we follow. On the other hand, in terms of cost reduction efforts, we believe that the most important thing is to continue relentlessly improving all manufacturing processes to further improve quality and yield and productivity, as well as maintaining equipment, and the most important thing is to develop people who can consistently produce stable high-quality products.

Japan is currently facing a demographic challenge characterized by a declining birth rate as well as a rapidly aging population. This change is severely affecting the workforce of Japan making recruitment more competitive and presenting a shrinking domestic market to sell products to. It is estimated that by 2040 Japan will face a shortage of over 10 million workers. What opportunities and challenges is this demographic presenting to your business?

The manufacturing sector is certainly taking the brunt of this shortage with the aging and declining population. There are many excellent companies in our surrounding area such as motor manufacturing industries, so it makes recruitment much harder. Fortunately, our chain production process doesn’t require many workers. We will develop human resources with high technical skills, a wide range of knowledge, experience, and the ability to operate machines efficiently, towards our next development. At our chain production factory, 50% of our workers are below the age of 35. We are developing a system for paring middle and young generations together. I used to be an engineer at Toyota Motor Corporation designing suspensions. I understand that a chain is a basic machinery element that is irreplaceable. Unless there was a totally new innovation that would replace the need for chains, there will continue to be ever-present demand. I see a great future for the growth of chain production.

The Japanese government recently announced that they are going to double the number of skilled foreign workers that they will allow to come to Japan. Are you looking to leverage this situation now that the Japanese visa situation has become easier? Are you looking to recruit Southeast Asian workers to help bolster your workforce?

We aren’t in a state right now where we are actively recruiting foreign workers. But many foreign workers are employed in the assembly process of automobile parts even now. The weak JPY has a downside. And we are worried this downside is making Japan less attractive as a place to work from the perspective of foreign workers. Even people living in Japan are struggling since the JPY has weakened so much.

One of your strong points is the automotive sector, an industry that is seeing a once-in-a-lifetime shift towards EVs. In order to facilitate this change there is a need for new materials that are lightweight. Have you had to make any adjustments to your products in order to cater to this shift in the automotive sector?

Lightweight is an eternal theme of the automotive industry. We have always been making efforts for high strength and lightweight. As far as developments of new products go, we want to move onto pressed or welded parts that are specifically designed for EVs and hybrid vehicles. In this once-in-a-century revolution of the automotive industry, we want to have a part to play with new products.

Our company was established as a snow chain manufacturer but the demand for snow chains is decreasing year by year due to improvement and spread of studless tires. In recent years we have seen heavy snowfall in Japan. To cope with this situation, the Japanese government made it mandatory to equip snow chains in heavy snowfall areas. And snow chains are indispensable for buses and trucks when snow falls. Although overall demand may decrease, we think there will still be constant demand. We will continue contributing to the safe driving of cars during the winter season.

You’ve already mentioned some of the benefits of your HydroFree technology such as its speed and the fact that your technology can cater to longer chains. What other advantages does your method provide you over the processes of your competitors?

The conventional method will generate hydrogen during the galvanizing process. Hydrogen is absorbed by the metal. Especially hard metals more than HV400 Vickers hardness, which indicates hardness characteristic of metal, have a risk leading to hydrogen embrittlement and delayed fracture.

The strength of the chain is an important aspect in contributing to anti-corrosion characteristics. The linking part especially needs to stay strong and firm. On the other hand, to do so metal plating is important in order to give the metal some form of surface treatment. All chain companies are struggling to balance out strength with surface treatments.

Conventional methods heat up the metal to 200 degrees Celsius and carry out a baking process to let the hydrogen go. The idea is to scatter the hydrogen within this structure in order to instigate the natural emission of hydrogen out of the metal. Depending on the situation and condition this doesn’t necessarily happen which means things are never really certain. We have attempted this conventional method, but in order to increase the certainty, raising the temperature is important. The downside is that by raising the temperature too much it would destroy the carbonization layer and compromise the rigidity of surface treatment.

HydroFree is a method of eliminating the possibility of hydrogen generation infinitely by pursuing an electronic galvanizing mechanism from the root.

HydroFree enabled removing the time-consuming baking process while achieving high strength. Compared to our competitors our method results in stronger chains, and with our technology, we are able to achieve a hardness rating of HV700, with our competitors only being able to achieve around HV600. By having a much higher strength chain process we are able to reduce the amount of abrasion that occurs massively. I think that a real uniqueness we can boast of is that not only has this technology been developed in-house but also the equipment and machinery necessary. The engineer responsible is only in his 40s, meaning he is still relatively young. I am very happy to say that our company is led by a younger generation of both engineers and workers.

Within your own production processes, we understand that you have a very strong emphasis on quality control. Could you talk about some of the specific quality control measures you have put in place in order to meet some of the high standards required by the industry and clients?

First and foremost, our company has a presence within the automotive industry, an industry that is known for having very high standards for quality control. Having been nurtured in the industry we have grown to be able to standardize our production to such a high level and this is all thanks to our experiences in the automotive industry.

By having chain and automobile parts business which are two pillars, we can utilize the synergetic effect. This synergy ensures that the quality of our output is of the highest level. Due to the nature of the chain, all chain links must meet quality and shape requirements. We are actively introducing quality control and production control techniques of automobile parts into the chain production process. To ensure that everyone faces the same direction we carry out daily training activities for staff and regular maintenance on our equipment.

A chain is composed of multiple links and even a single failure of the link will put a life at risk. We constantly do inspections on every single link we produce. This works in unison with our continuous galvanizing surface treatment techniques.

Present within the Japanese automotive industry is the Keiretsu model, where big tier-1 companies are supplied by component makers in tier-2 and tier-3. Traditionally this has been the strength of Japan’s auto industry and lower-tiered companies were able to cater to the specific needs of tier-1 and parent companies. As we have mentioned in this interview however, Japan is experiencing a number of disruptions including the population decline, but if we talk about the automotive industry in particular, it is being upturned by the transition to hybrid vehicles and EVs. There are a number of new entrants and startups appearing all across the globe. Obviously, your company is very closely aligned with Toyota and Chuo Spring as parent companies. Beyond those traditional Keiretsu customers are you looking to expand your sales base? Is there a sense of urgency to look overseas?

Regarding our automotive parts provision, we are still in the early phase since we have a relatively short history of dealing with this kind of product. We value the current customer portfolio and we are prioritizing catering to their needs. At the same time, while we do want to open up more to other clients, we are still currently at the stage of only working with tier-1 customers. This is because we work with those Keiretsu firms to determine the best application for our technology as well as evolve our technology.

As for our chain business, we are considered one of the leading global manufacturers of chains, so we are actively looking for new applications and new customers through our provision of high-quality, specialized chains that meet our clients' every need.

You mentioned looking for new customers and we know through our research that you export directly as well as through distributors in countries like China and Taiwan. What location is next and what sort of customers would you be looking to export to?

We want to find our way into more socially contributing businesses such as supplying components for wind turbines and maintenance hoists. We have received requests in this regard from China and France. Ideally, we want our company to make contributions towards SDGs and achieve carbon neutrality through our technologies. In terms of SDGs, we are thinking that wind power generation will continue to expand. We are hoping that market needs will grow from now on in Japan, which is lagging behind compared with other nations, especially Europe, the US, and China.

The countries right now that are experiencing rapidly growing populations are mostly in Southeast Asia and India, and with that growth comes emerging economies. We have received contact with those countries so I would say that Southeast Asia and India are areas we are interested in.

Although I gave the example of the maintenance hoist, industrial chains still remain our main pillar of business. Wherever there is economic growth and construction there is a need for mechanical chains for the machinery. We want to constantly be able to provide high-quality products to fields where there is constant demand.

Imagine that we come back in three years and have this interview all over again. What goals or dreams do you hope to achieve by the time we come back for that new interview?

Frankly speaking, we receive more customer orders than we can readily supply so it is very important for us to strengthen our production capabilities so that we can better provide our products on a timely basis, especially in this rapidly changing society. The strengthening of our automotive component business is important to us with the decline of the population; efficient production in a less costly manner has become more important than ever before. We want to fully leverage the experiences we have in the development of chain manufacturing equipment to produce our own unique equipment for producing automotive parts.

We are located in Hamamatsu City and our main customers are in Aichi Prefecture. There is some distance, so we will improve productivity by compensating our logistics. The sales ratio of the chain business is currently 40% and by developing the chain business, we will increase this to 50%, which is the same ratio as the growing automobile parts.

We produce chains daily in several hundred meters long units. We are always aware that “A chain is only as strong as its weakest link”. A chain is a product that if a single link is weaker than anticipated, it must be eliminated during its development and manufacturing. However, depending on how it is used, some parts may be replaced with little or no functionality. However, we manufacture our chains with confidence and pride. A chain is an industrial product that is usually hard to find and is like the "unsung heroes" that work hard behind the scenes. However, the chain is a basic part of everyday life that can be found anywhere. I hope this will encourage you to pay a little more attention to chains.

For more information, visit: www.fecchain.co.jp/english

0 COMMENTS