In this exclusive interview, Nippon Tanshi's CEO shares gripping insights into navigating supply chain disruptions, revolutionizing automotive connectors, and steering towards sustainable growth in the dynamic landscape of Japanese manufacturing.

It's an exciting time for Japanese manufacturing. The past three years have seen significant supply chain disruptions due to COVID as well as the US and China decoupling; as a result, corporate groups are looking to diversify their suppliers for the sake of reliability. Japanese firms, known for their reliability and advanced technology, find themselves in an interesting position, which many observers argue is a once-in-a-lifetime opportunity in conjunction with the weak yen. What would you say the advantages of Japanese firms are in this current macro environment?

Many Japanese companies are facing the difficulties posed by global supply chain disruptions. It's becoming increasingly important to plan for supplier diversification from the perspective of risk diversification rather than as a result of globalization. Because connector manufacturers also procure overseas materials and manufacture at overseas locations, this problem is a significant issue that we have in common.

Most suppliers of Nippon Tanshi are Japanese, but the shortage of metals--a key material--has become so severe that we're looking into overseas metals. It's evident that many Japanese companies are still struggling on various fronts due to logistics being disrupted by COVID-19 and the war [in Ukraine].

On the other hand, we're definitely sensing a trend toward returning to domestic procurement and production.

Japanese companies may also be investing less aggressively in China, a shift that was visible both before and during COVID's three-year run. At present, we're seeing a trend all the more toward manufacturing in Japan for in-demand products that require not only high quality but also supply stability. In an age of such unpredictabilities as COVID-19, domestic suppliers who can manage somewhat of a read on the macroenvironment may feel that they're mitigating risk. You have to opt for domestic production while reassessing and re-evaluating overseas risks. Doing so ensures that you fulfill your responsibility to supply your customers, and also reduces lead times.

Japan has the world's oldest society with a rapidly shrinking population. This presents certain challenges, including a labor crisis and a shrinking domestic market. What challenges has this presented to your company, and how have you been addressing them?

This is an issue for many Japanese companies, but how to deal with the shortage of human resources is a major management challenge for us. BtoB companies, in particular, have an increasing need to seriously tackle how to establish their presence. For example, using a smartphone doesn't make you aware of what parts it contains or what companies made them.

We've been supporting our local J1 football team, Shonan Bellmare, for 11 years now. In the beginning, we just wanted to give back to our local community, but it's also become a great way to get our name out there. We also support the Shonan Bellmare youth team by putting our company name on their uniforms, and in July of this year, we partnered with the San Diego Padres, a Major League Baseball team, for their Japanese heritage celebration day. The hope is that directing attention to our name during games might pique interest in our company; then, when people search for "Nippon Tanshi" online and find out more about our business, they'll end up working with us.

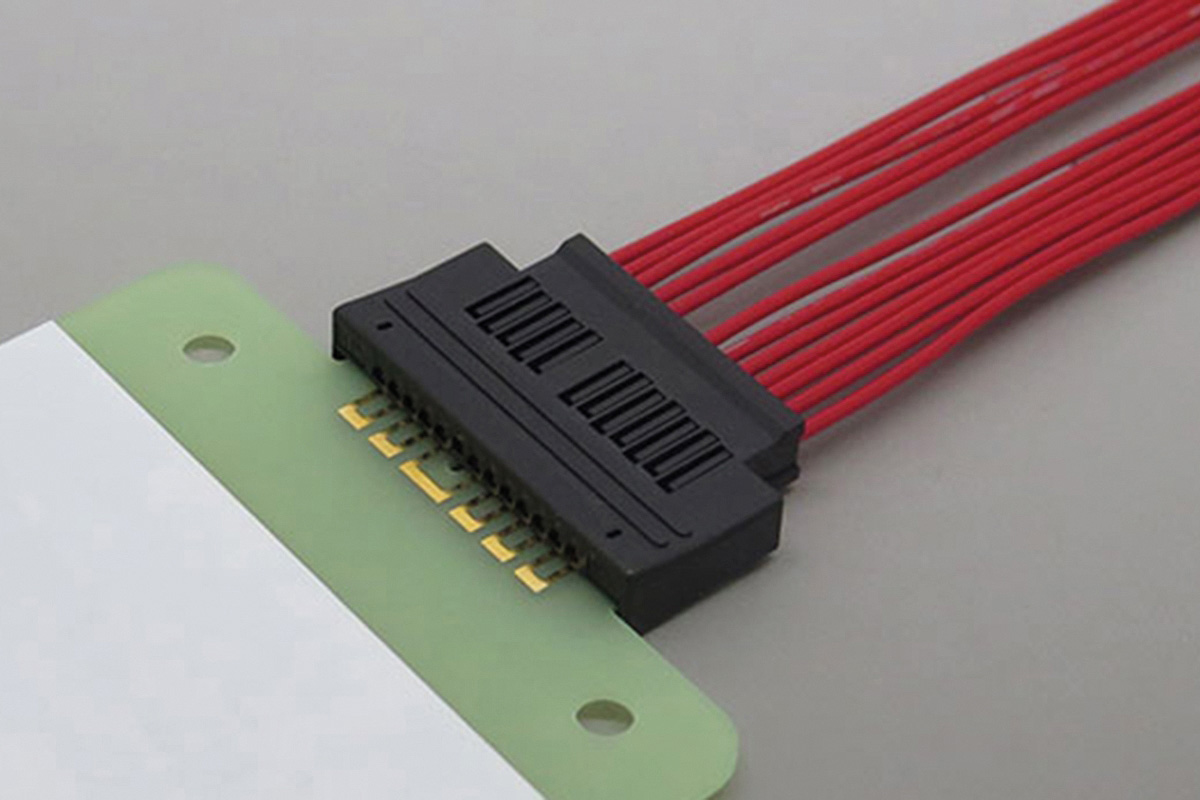

K86/K91 Series

Your products are used for various applications in a wide variety of industries, including home appliances, OA equipment, automobiles, and communication devices. Is there a specific application that you're focusing on right now? Or are there any new industries or applications you'd like to step foot in?

Our focus is on automotive applications. Many of the connectors and terminals we currently release are for this market, which we believe will continue to be an important client. Because automobiles are equipped with so many different types of connectors, we'd like to continue fully meeting the needs of this market.

We're also planning our business portfolio for other markets. For example, the consumer electronics market, which includes sanitary products like warm-water bidets or major home appliances like washing machines.

Cars are increasingly becoming computers on wheels, with an increase in electronic components raising the need for connectors. However, the inside of a vehicle is harsh; it can get extremely warm, and connectors must function in harmony with the entire system. What specific products are you developing or releasing to accommodate these unique properties of the automotive field?

Just as you say, the automotive market is currently undergoing a once-in-a-century transformation. For example, one recent major change is that vehicle lights now use LEDs. This resulted in more connectors being used, which completely changed both the configuration and design of the electronic components.

Before we introduce a product to consumers, there's a long road of development, which starts with basic research. Even with the LED vehicle light, you have to solve situation-specific issues like how to deal with high-temperature environments, but we are determined to develop technologies that can meet future market needs.

One example of our development within automotive connectors is the "@SeesawEdge," a type of card-edge connector, which goes by the series name K86 or K91. Traditionally, card-edge connectors weren't actively used by Japanese car manufacturers in light of "connection reliability," but Nippon Tanshi developed and patented a new mechanism to ensure a reliable connection; now, they're used in automobiles. The terminal that conducts electricity in the Seesaw Edge moves like a seesaw to make two points of contact with the board, hence the name.

We're now receiving quite interested inquiries from carmakers and Tier 1 manufacturers, so we're excited about its future.

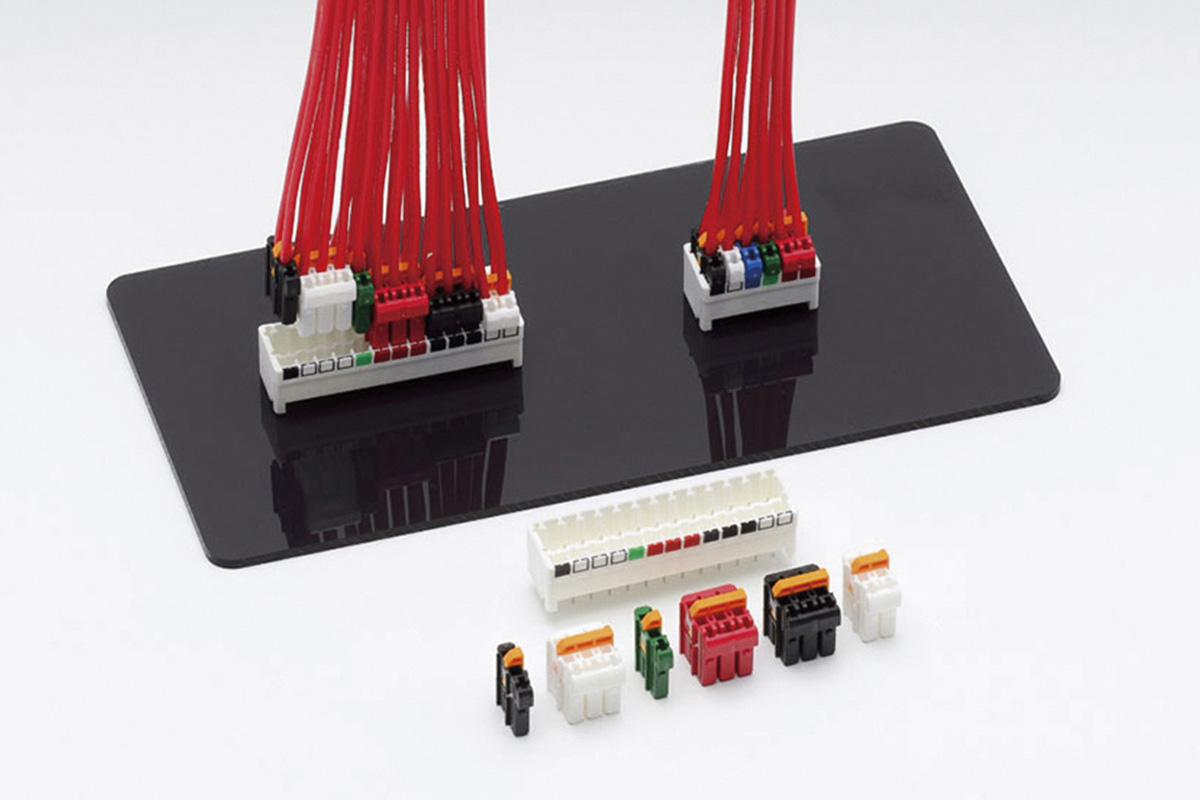

K87 Series

In addition to the increase in electronic devices, there's also a trend toward EVs and hybrid vehicles. Moreover, automakers like Toyota are trying to maximally reduce [vehicle] weight to make their cars function with larger batteries. How do these two major trends in the automotive sector affect your business?

The shift toward electric vehicles has been both a tailwind and a morale booster for our company. It's been said that more connectors will be used with the change from engine to motor power. The shift to EVs and hybrid vehicles is a great business opportunity for us, as it will increase the number of high-voltage terminals and connectors, both of which are Nippon Tanshi’s strong suits.

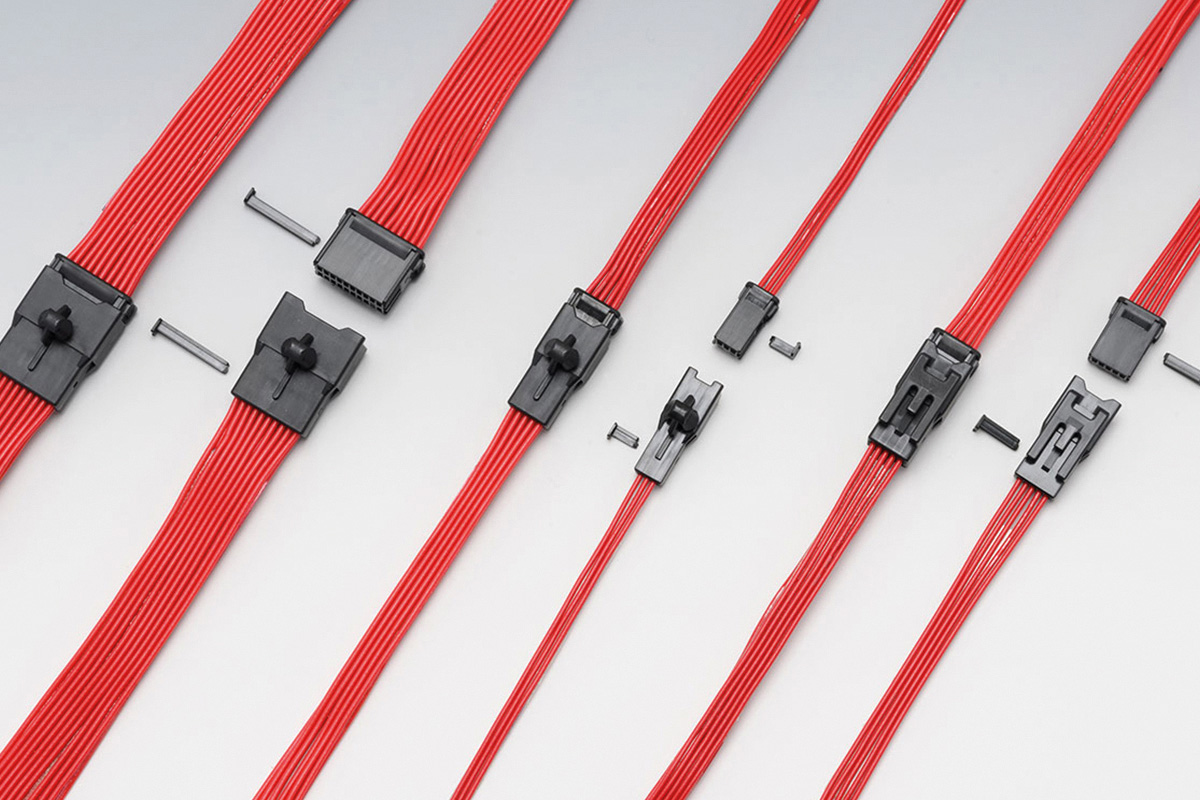

Regarding your second point of weight reduction, we're trying to achieve this by using smaller electronic components. As evident in our development of the K87, we place importance on utilizing the ideas of our creative engineers to achieve miniaturization. At the same time, we look forward to meeting the needs for improved performance and productivity as more and more large-size, high-voltage parts will be produced due to the shift toward EVs.

This spring, we acquired the former site of the Kanagawa Brewery of Asahi Breweries in Minami-Ashigara City in Kanagawa Prefecture. The plant occupies 400,000 square meters, or eight Tokyo Domes. Here, it will be possible to locate large facilities for the production of large high-voltage components. This expansion was planned to meet increased demand and also planned from a BCP perspective.

One last thing, but we'd like the facility to function as a center for Nippon Tanshi's sustainable businesses. We chose this site for its abundant nature and pleasant environment. We aim to make a positive contribution to the local environment and community. By establishing this base, we're preparing to start operations at the end of next year, both domestically and globally.

What role would you say partnerships play in your business model? And as Nippon Tanshi has said before, are you currently looking for partnerships in overseas markets such as Europe and the U.S.?

The main purpose of our overseas partnerships is to increase the speed at which we gather cutting-edge information. We now have offices in Chicago, Bangkok, and China, where our employees work hard to quickly grasp the needs of new automotive products.

High-population, rapid-growth markets like India are also appealing to the automotive industry. I recently visited Delhi and could see why people say "India is next" given its resemblance to China's economy 10 years ago. I'd like to focus on India.

K89 Series

You specifically mentioned the goal of expanding exports to markets such as the United States, which I find quite interesting. This expansion has led to the establishment of a new factory. Can you explain the rationale behind your decision to establish a new plant in Japan rather than overseas?

For one thing, connector production has been largely automated, so the cost advantage of producing overseas no longer has the same impact. Manual labor has been greatly reduced.

Quality is the most pressing issue for connectors, as they're a critical part of automobiles. Domestic production, which is easier to control, allows for a higher level of quality assurance and consistent reliability.

Procuring materials is also an important upstream process, especially metals. Fortunately, we've established long-term partnerships with Japanese manufacturers and have strong cooperative relationships with them, so we decided to strengthen our domestic production for the sake of supply stability.

A recently launched product that garnered attention is the K87 series. This product is designed for a variety of applications such as home electronics, home appliances, and automotive electronics, and also plays an important role in board-to-wire connections. What motivated the development of the K87 series, and how does it differ from other connectors on the market?

The K87 series was developed based on the concept of integrating connectors--an idea conceived by our engineers--which resulted in a smaller board area and overall size. This innovation also provides the great benefit of cost reduction to the user, our clients, by eliminating the need for wire-to-wire connectors, thereby reducing the number of connectors and man-hours required.

Moreover, when pairing connectors (combining a male and female end), we used colors to prevent combination errors, allotting for so-called mismating prevention.

Imagine that we have returned for another interview on your last day as CEO. Is there a particular goal that you would like to have achieved by then?

I have no grand ambitions, but I am certain that we have taken many steps in the development of the company so far. I took over as president just after the Lehman Brothers collapse, which was a very difficult time. The financial situation in the years following the Lehman collapse was not good, but we have since been able to improve our performance significantly and our sales have almost doubled.

For my long-term vision, I've set a sales target of more than 40 billion yen, but at the same time, I believe it's important that people know our company by name and understand what our products are.

Since our connectors play an important structural role in applications, they must be reliable. We strive for our customers to say, "You're in good hands with Nippon Tanshi."

We take pride and pleasure in manufacturing our products and have worked hard to earn the trust of our customers through manufacturing. Our ultimate goal is to continue to build even stronger relationships of trust with our various stakeholders, including local residents, students, and those who are committed to sustainable management.

0 COMMENTS