Unveiling the power of brewed protein innovation, shifting startup culture, and the quest for world peace through bio-manufacturing in a changing economic landscape.

It is our view that Japan is at a very exciting time for industry. On one hand, we have had major supply chain disruptions in the last three years, caused by the COVID-19 pandemic as well as tension from the China-US decoupling situation. As a result, we are seeing many multinational groups try to diversify their supply chains with a focus on reliability. This is where Japan can enter; a country known for decades of high reliability, trustworthiness, and short lead times when it comes to production. Now, with a depreciated JPY, it is our view that there’s never been a more opportune moment for Japanese manufacturers to meet the pressing needs of this macroeconomic environment. Do you agree with this premise, and why or why not? What are the advantages of Japanese firms in this current economic environment?

We believe that this environment provides a big opportunity, and we are looking to strengthen our own position. With supply chains changing we feel that the timing is good for startup companies such as ourselves as well as technology-focused companies that are based in Japan.

You mentioned there that you are a startup company, and the US has historically been known for having a lot more startups than Japan. While Japan does have a growing startup ecosystem, unicorn companies like yours are more of an exception rather than a rule. Why do you believe Japan’s market produces fewer unicorns than other developed nations? How do you think the startup culture in Japan has changed since your foundation in 2007?

First of all, I would describe Japan as a medium-sized market, so if a company only looks inward there is a kind of limit to the size it can grow to. Also, with the language barrier present, it becomes difficult to really target the global market. There aren’t many startups that can have that kind of reach.

Spiber was founded in 2007, but if we look back even further to around 2000, there weren’t really many large startups in Japan. I think the reason for this is that investment systems such as angel investors really didn’t exist back then. It was really hard to get investment from groups of people and for them to take a risk in investing in a new company or a new technology. It is easier to have one person like an angel investor as opposed to trying to get a consensus from many people.

In the past 20 years or so the environment has changed in Japan, and those systems for investment have been updated and improved. However, if you look at the US, they have huge investors like Mr. Jeff Bezos and Mr. Elon Musk. That type of investor doesn’t exist so much in Japan. If a company wants to receive significant investment, the US really is the place that has the ecosystem for that. To be completely honest, the hurdles we face in Japan are quite high.

When it comes to having one person who has both a great vision and the financial resources to invest in that vision, that is something that is much more prevalent in America than in Japan. In fact, Japan tends to rely much more on the consensus of a group of people over the vision of one investor.

Why do you believe your company was able to succeed and become one of the very few Japanese unicorns?

Since the foundation of the company, we’ve had a sense that our customers would be from all over the world, not just in Japan. We also understood that if we didn’t have the number one technology in our field, it would be very difficult to secure investment. We have to be focused on being the leader of the industry and have worked very hard to stand out when compared to our rivals. We are also very lucky in the sense that we have been able to attain the results that we have. Once we achieve those results it allows us to go and get more investment, which in turn attracts more talent to us, which then allows us to continue our R&D and get results, so it's quite cyclical in that sense. Essentially, we entered this kind of positive feedback loop, which did require an element of luck.

The technology you are known for is your Brewed Protein material, which we understand is a lab-grown, plant-based fiber, resin, and other types of material that are manufactured through microbial fermentation. This Brewed Protein can be used to replace materials such as wool, cashmere, and silk. How have you built upon the Brewed Protein material in the last two years since we interviewed you? What investments have you made in the past two years?

One of the main results that we’ve accomplished is production in our plant in Thailand. Mass production of the Brewed Protein material you mentioned has started there. Now, in addition to material from our plant in Japan that has already appeared in various products, Brewed Protein material produced in the Thai plant has been processed into fibers and is being sold in actual clothing products in autumn and winter 2023, which we feel is a very big milestone.

Technological development for alternative materials to wool, silk, and cashmere is still ongoing, but the next big area that we are focusing on is food. When you think about the three core things people need to live, many tend to think of food, clothing, and shelter. We feel that for food and clothing, our materials can really contribute to those fields.

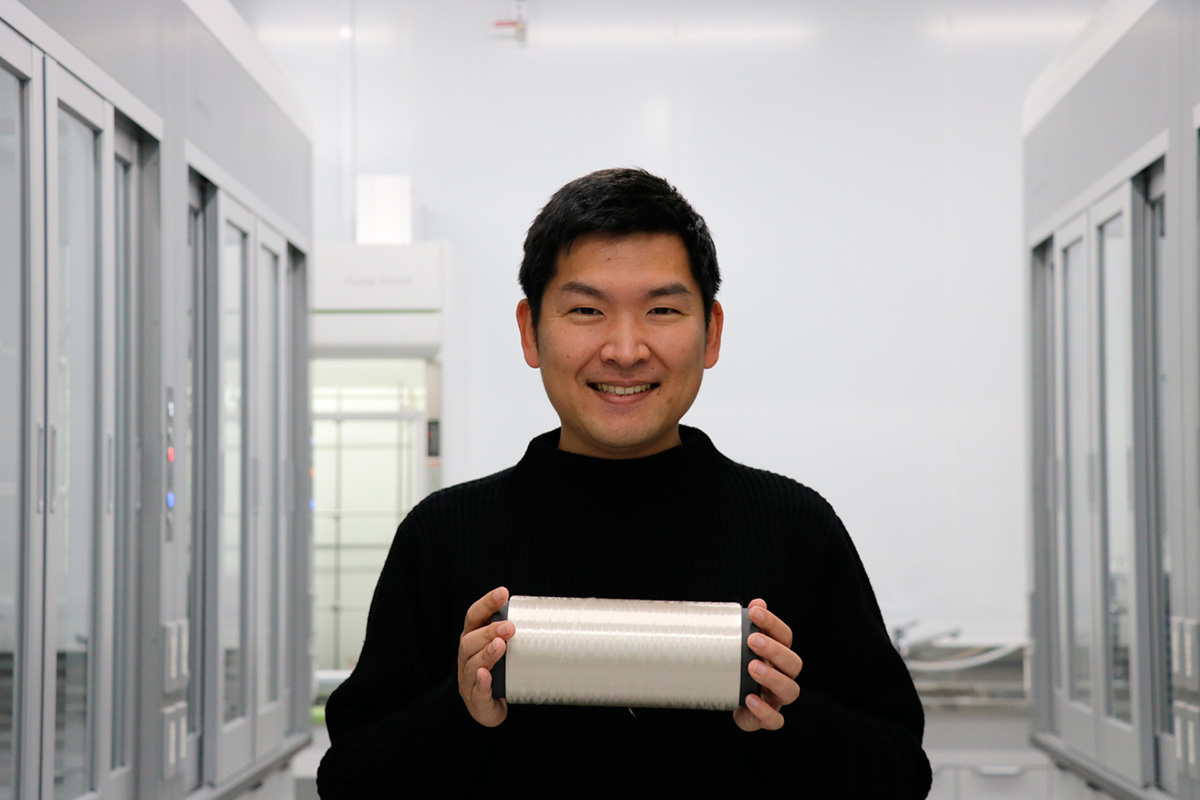

Examples of processed Brewed Protein™ materials designed by Spiber

Can you elaborate more on your expansion into the food industry?

In the field of food, we are involved in various research and development projects, but the key reason why we are doing this is because humans need protein to survive. As the population of the world increases and consumption also increases, there is a risk of protein shortages. The amount of meat people eat from livestock is also on the rise, and that number is an unfathomable amount—I think around 300 million tons a year. It is a huge task to satisfy this demand from livestock alone, so what we would like to do with our process is take and use biomass materials and feed that into our microorganism fermentation process to create protein materials. Those materials can then be used for human consumption.

Do you have a timeframe for when this protein for human consumption will be ready to go?

Technologically speaking, we’re already at a good place with the meat products at the lab scale internally, and in fact, we’ve already added some of our fibers into meat and created tasty, juicy steak prototypes from that. The next challenge is to figure out how to increase the production scale and maintain quality at mass production scale. We are thinking that the latter part of the 2020s is our initial target.

One of the other difficult hurdles is regulation, and in order to spread this material for human consumption around the world, we need to meet those regulations. With our processes, we use microorganisms and we have a recombinant protein-based process, so in the US or anywhere else in the world, there are regulations regarding that process. Over the next 10, 20, or even 100 years we believe this is something that is very important for the survival of humanity, so for that reason we want to continue developing this technology, proving its safety, and developing a biomass-based supply chain that can produce these materials.

You highlighted some of the difficulties when it comes to maintaining quality at a production level as well as the regulatory issue. One way many companies have overcome some of these challenges they face in terms of regulations is through partnerships. Are you looking to partner up with foreign firms for regulation purposes or R&D purposes?

We do believe this is a possibility and already we are working with ADM, a food processing company in the US. In each country around the world, we will have to find a local partner to work with, not just for the development of the technology, but also for the production of the materials.

Earlier you mentioned how your brewed protein material being produced on a mass-market scale was a key milestone for your company. Globally we know it is being used as part of brands such as The North Face, Goldwin, Nanamica and Woolrich. This was rolled out at the end of September 2023 and right now we are in October 2023. Given that it has only been one month, what has the initial reception been for this collection?

I personally went to the shops on opening weekend as well as the following two weekends. When I was there, I saw a lot of business going on and people buying lots of things. What I was surprised about most was that there were people there who did not know about Spiber—they just happened to go into the store and felt that the clothes looked and felt very cool. They didn’t come specifically because of Spiber or because of sustainability, they just came naturally.

Compared to some other products the price is a bit higher, but overall we have had a lot of good feedback about the materials and the designs. This has surprised me in a very positive way.

Products using Brewed Protein™ fiber were released domestically and internationally as part of the 2023 Fall/Winter Collection by four brands: Goldwin, The North Face, nanamica, and Woolrich. This collection marks the first mass-produced collection to be sold on a commercial scale since the start of operations at Spiber’s Thai plant.

Source: GOLDWIN INC.

Given the positive reception so far are you looking to work with more foreign brands going forward?

Yes, we are.

Obviously, you mentioned sustainability has been a core part of Spiber, and we know the fashion industry in general contributes about 8% of global CO2 emissions. If we look at fast fashion as just an example, more than 10,000 items from this trend go into landfills every 5 minutes. One way to combat this is through your Brewed Protein material which is a very eco-friendly material, but in your opinion, how else can the fashion and textile industry reduce its environmental burden?

The important thing we think about is shifting from a linear economy to a circular economy. In the apparel industry in particular, circularity is very low. Spiber’s original motivation was based on the realization that resources in general like land, food, and oil are all limited resources. That leads to concerns that as resources dwindle, there will be a signifacnt impact on humanity, which could lead to war and suffering, so during the foundation of Spiber, we asked how we could address this problem. The main goal was to create things that are needed by the greatest amount of people. In this sense, we feel that figuring out ways to utilize the resources we do have in a circular manner is very important.

100 billion tons of materials are used by humanity every year, and only 10% is recycled. In the apparel and textile industry, fiber-to-fiber circular recycling is even lower, going as low as less than 1%. This is a problem that we are working to address.

You are now in Thailand and you also have a location in the United States, but in 2022 you also opened a Paris office. Moving forward, which countries or regions have you identified as key to the growth of Spiber?

First of all, our locations in Thailand and the US are focused on producing protein powder, which is the final product that comes from those locations. Right now, we are shipping that powder back to Japan, where we process it into fibers and other forms. We take those materials and put them into products that we then sell. This is a simple explanation of how our supply chain is operating right now.

For our location in France, we have a lot of product development activities with companies around Europe. We are talking with luxury brands—including some that we have yet to announce publicly. We realized that we needed to have a physical presence in Europe in order to actually facilitate communication with those brands and those companies. I would say that our France office is more of a sales office. Each location has a role to fill, and they are all connected to help bring this material to the world.

Of course, we understand that in order to actually spread our products throughout the world, we have to have a good product to begin with. It has to be something that people think is high-quality and something that people think is cool. We are working hard to create good fibers and good products and continue the development of this technology. In Europe, there are many fiber mills, and we work with them to create good fibers and textiles that consumers would like. While we are already working closely with Japanese manufacturers and continue to develop high-quality products, our vision extends to China as well, where we expect to work with local mills and manufacturers.

Imagine that we come back in four years and have this interview all over again. What goals or dreams would you like to have achieved by the time we come back for that new interview?

As I mentioned a little earlier, the whole Spiber project came about as a way to make contributions towards world peace. This is something I’ve felt very strongly about since high school. As a student, I learned about biotechnology and I learned that biotechnology could be a way to maximize my contributions to this goal of world peace. I then entered Keio University, and the seeds of my inspiration began to sprout around 2004. As a company, Spiber was founded in 2007, so we are coming up to 20 years where I’ve had the same goal. Each year I’m making steps towards that goal, and it feels like I’m finally at the starting line of this project now that mass production is up and running in Thailand. We hope that in the next 2-3 years we will be up to full capacity there, which would be roughly 500 tons per year. However, that is very small compared to the world’s needs in terms of fiber and meat consumption. The long-term goal is creating millions of tons, but in order to get there we need to take things one step at a time. As you can see, this is simply the start for us, and over the next 20 years, we are thinking of how we can increase our production by orders of magnitude more than what we are doing right now.

In the upcoming decades, we are looking at how the bio-manufacturing and chemical supply chains interact, and we feel that they can be leveraged together. We feel that we have a lot of potential to contribute to the biology side, so the question then really becomes, “Where do we fit in?” There are many people around the world who are contributing to this project, and it isn’t just a Japanese project. We are interacting with people, companies, and technologies from all around the world to achieve this goal.

0 COMMENTS