The interview features an insightful discussion on Japan's industrial landscape, focusing on the challenges and opportunities faced by a company specializing in conveyor belt cleaning systems. It touches on various topics, including Japan's attractiveness on the international stage amidst supply chain disruptions and currency fluctuations, demographic challenges such as an aging population and labor shortages, and the company's strategies for adapting to these changes.

We believe that Japan is at a very interesting time right now. Due to the supply chain disruptions caused by COVID-19 and US-Chinese tensions, coupled with the record low of the JPY, we think that Japan is once again very attractive on the international scene. Do you agree with this premise, and what would you say are the key advantages of Japanese companies in this current macro environment?

When it comes to the exporting business, I agree with your sentiment. However, it is the opposite for the importing business. The importing of ingredients is not an issue for our conveyor belt cleaner business. However, as a trading business, we import a lot of ingredients for packaging materials from China and Vietnam for example. The cost of these ingredients has recently increased. After the Covid-19 pandemic, many Japanese companies shifted their factories from China back to Japan. As you know the monozukuri manufacturing business is our basic industry in Japan, and Japanese products are widely known to be very reliable and of high quality and high functionality. However, at the same time, Japan is facing problems related to its population decline. The Japanese population is aging and companies are facing issues when it comes to the recruitment of young graduates.

As you mentioned, the Japanese population is known to be an aging population. It is expected that by 2050, the population will drop below 100 million people. This raises two major issues. The first one is as you mentioned a labor force shortage while the second is a domestic market that is slowly but surely shrinking. In that context, how has your firm been adapting itself to this demographic shift, and to what extent must you look overseas to ensure long-term business success?

Like other Japanese companies, we are having difficulties with recruitment. Talented employees tend to want to work for the larger famous companies in Japan. This has led to SMEs struggling to find talented employees. In the future, this issue will only worsen due to Japan's demographic situation. We have to increase the appeal of our company to attract young talented employees to join us. This not only applies to the office but also applies to the factory as well. We are trying to automate our factory operations as much as possible. That requires us to invest a lot into our facilities while also keeping up a stable supply of our products for delivery to our clients.

Your company’s products be it on the trading side or the manufacturing side mainly serve heavy industries in construction-related fields. The construction field in Japan is experiencing this demographic situation ahead of other fields. Today, one-third of construction workers are already over the age of 65. While it is a big challenge, it is also an opportunity for companies to provide automated solutions and produce the same amount of products with less manpower. Let us not forget, that while Japan is at the forefront of this demographic trend, other countries are also aging with countries such as Korea, China, and the US in the same situation. What opportunities do you see as construction workers age? Is your firm also looking at creating technologies that could lessen the need for manpower?

The retirement age is changing in Japan according to the policies of the Japanese government. Before, 60 was the retirement age. However, that is now increasing to 65, and by 2025, the retirement age may be 70. In my opinion, in 10 years, it could be even higher. The jobs in factories including our own require some manual work to be done by highly-skilled workers. Those skills need to be passed on to the younger generations. However, this is something that will take a lot of time. When it comes to automation in our factory, welding is one of the areas that we are trying to automate.

Over the last decade, we have seen the rise of regional manufacturers from China, Taiwan, and Korea for example, who have replicated the Japanese model at lower costs. Despite this, Japanese companies remain leaders in niche B2B fields. How would you define your company’s core strengths when appealing to prospective foreign clients?

First of all, we are a chusho kigyo. However, one of our strong points is that we are in quite a strong financial position, and we run our company without debts. This year is the 72nd year since our foundation. Over the years, we have been able to build a successful and sustainable business, and our strong financial position allows us to make big investments in equipment for example.

When it comes to our belt cleaner division, our products are well known for their high quality, high functionality, and high reliability. Many of our competitors are trying to copy our products. They sell similar products to us. However, when you compare the cleaning results of our products and our competitors, our products are superior. That is why our equipment sales numbers are growing.

Historically, you have been a trading company specializing in rubber and plastic materials. Since 1969, you started the commercialization of your brand Belle Banne, and your Bell Burn conveyor belt cleaner, which you have diversified since then with some wear-resistant ceramic liner and ceramic lining material among many others. Why did you decide to diversify and become a manufacturer? What were the challenges of moving from a trading background and becoming a manufacturer making these kinds of products?

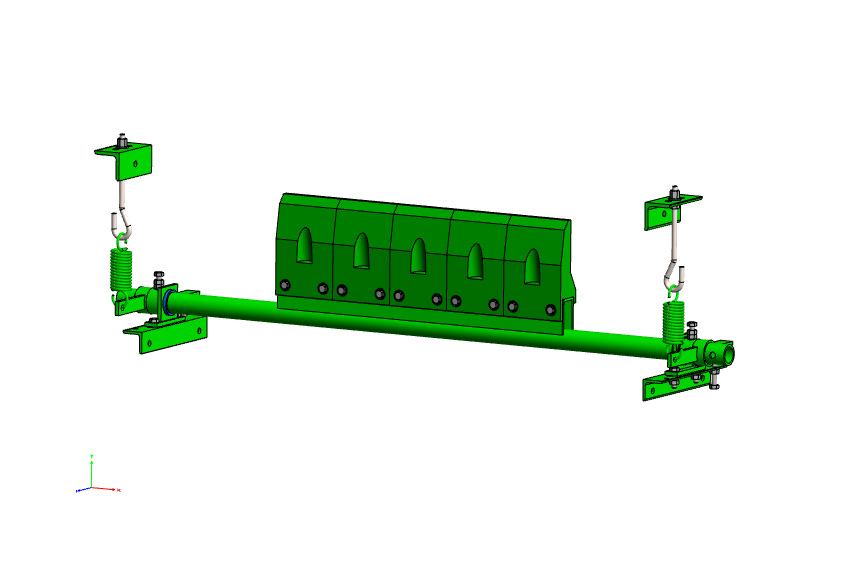

Bell Banne products

When we began to sell our Bell Banne products, we received lots of requests not only related to the product itself but also to the surrounding area as well. We started to listen to the needs of the market and we began to develop other products. That led us to where we are today, which is a total solution-providing company for our clients.

One of the interesting materials we saw that you developed was your Bell Lagging which is a composite material comprised of rubber and ceramics. Usually lagging materials that are utilized on conveyor belts and pulley systems are made from plain rubber. What are the advantages of the Bell Lagging compared to traditional rubber lagging alternatives?

Rubber is a weak material when it comes to wear resistance. That was why we started to use a different material. As you know, when you press rubber, you lose tension in exchange. This can be time-consuming. The user needs to stop their operations which also costs money. Our Belle Lagging material has excellent wear resistance which ensures a longer life. The material’s grip strength is also harder. We tried to make the friction rate higher. Spikes get into the rubber, so by making the friction rate higher you can eliminate the slipping of the drive pulley.

Belt cleaners play a crucial role in maintaining the running of the system. However, they also pose a risk in terms of damaging the belt itself. The presence of a belt cleaner is bound to result in some regular wear due to extended use. If the belt cleaner is not well installed, it can lead to excessive pressure being placed upon the belt or significant chatter in the cleaner blade itself. Chatter can be particularly damaging, sometimes resulting in gashes or bulges in the belt. How do you overcome these challenges and provide a reliable and easy-to-install conveyor belt cleaner?

The conveyor belt moves both horizontally and vertically. We therefore have to first adjust each belt conveyor to ensure that the belt cleaner is stable. That is the key point. The belt cleaner must be able to follow 360 degrees at different angles. That is our core technology. We joke that belt conveyors are like humans, and each belt conveyor has a different character or personality. For example, we installed five belt cleaners with the same settings. However, each belt conveyor operated differently, so we had to adjust them one by one. It’s similar to using a razor on your face. If you use it too hard, it can hurt you. We have the rubber editions which absorb the vibrations and apply the tips at the ideal pressure. We also have a very close relationship with our customers.

The solutions that you have developed target very specific problems that come from customer feedback. Your company has a big chance because you started as a trader, so you have a lot of contact with your customers. How do you think that your trading business is positively impacting your manufacturing business? What are the advantages of having these two functions within the company?

Our trading business and our manufacturing business are very different. Our trading business focuses more on the construction of bridges, and providing hoses, pipes, and sheets for construction-related industries. Our cleaner products are for clients in different industries. However, as a trader, we have contact with lots of different customers. This gives us new ideas for our business. Before we launched our belt cleaner business, our trading section had relations with steel mills. In the 1960s, there were no belt cleaner manufacturers. We had the chance to become the first. The steel mills were looking for solutions like belt cleaners. Our predecessors then came up with these solutions.

One of the major advantages that has made us successful in the belt cleaner business is our adhesive technology that we use between the rubber and steel sheets. That is one of our unique points. The second advantage we have is the cushion we developed to fill in the small gaps. As the belt cleaner always operates under conditions with a lot of pressure, our products have to be adjusted for each specific belt conveyor. We developed our technology to provide solutions to each of our clients.

Tungsten carbide wear applies pressure on the belt and makes it weak. That meant that the customers manually had to make adjustments, which was a lot of work as they may have hundreds of conveyors running in their factories. We invented self-adjusting systems to eliminate this excessive work and downtime, and this has been very much appreciated by the industries that we deal with.

Usually, the belt has a trough like this, and the materials stay at the center. The trough remains on the return side. If you try to put a straight tip through there, you cannot reach the middle. This belt cleaner has a U-shape, so when it passes it is automatically in the middle. This was revolutionary for the industry. It allows for constant adjustment, and that is the reason why this product has been so popular over the past 30 years. Some of our biggest customers are from France.

Although we invented this U-type product around 36 years ago, our competitors are still trying to copy it. However, they have not been able to do so. It is still the number one product in our industry. The long life of tungsten carbide helps. Our unique adhesive technology is also key. However, we cannot reveal the details as it is a secret. It is my ambition to continue developing our U-shaped products in the future.

You mentioned that you are targeting the global market with your products and that France was one of the biggest overseas markets for your products. When we interviewed other key players within the industry, they mentioned the importance of open innovation and finding local partners to combine their expertise to unlock these international markets. What role do partnerships play within your business model, and are you currently searching for new partners within these overseas markets?

In the future, we would like to work together with local partners in different countries. At this moment, however, we are only exporting our products to around 10 or 12 countries, which is a small number. I prefer to gradually expand into the international markets one market at a time. Considering our company's capabilities, we want to develop our business step by step.

We know that you are not only focusing on the domestic market. As you mentioned, you are exporting your products to between 10 and 12 countries right now. What specific location would you like to continue your international expansion in?

Moving forward, we will continue working with our Australian and European clients. We sell to those markets through our local sales distributors. The end users are cement or mining businesses. After-sales maintenance is very important. We have a maintenance division at our company called BB Services that sends our specialist technicians to the sites to teach the local workers how to carry out the maintenance for our machines. As I mentioned earlier, you must take close care of conveyor belt cleaners, as they are almost like a human. No matter how good the product is, maintenance is always required. Aftercare services are always difficult. You cannot make dramatic changes. We always include our aftercare services and maintenance when we sell our products. However, providing these services takes some time. That is why we want to continue to focus on our existing clients.

Our products are quite expensive and therefore require daily care. The part that wears the most is the edge and it must be changed after one year or 18 months. The reason for this is that it operates in severe environments.

Your company is this year celebrating its 72nd anniversary. Imagine that we come back to have an interview with you again in 8 years for your 80th anniversary. What dreams or ambitions would you like to have achieved for the company before your 80th anniversary?

I am 62 years old, so I am not sure if I will be still working for the company by then. I am the fifth generation at this company. I became the CEO in April 2020. The Covid-19 period was quite a difficult time for us. Our company has over 100 employees. I had to take care of our employees and their families during that time.

Our trading division accounts for roughly 80% of our business with manufacturing accounting for 20%. In the trading business, there are lots of competitors, and the profit rate is quite low as we are selling standard products to clients. On the other hand, our manufacturing business is highly profitable. In 2020, we achieved JPY 8.9 billion in sales. When I became the CEO, I told the press that in three years, we would achieve sales of JPY 10 billion. However, due to Covid-19, we could not achieve that, so I postponed the target for one year. The end of our fiscal year will be in February, and I hope that we will achieve my goal by then. Hopefully, in the next nine years, our successors will find new markets for our next-generation products. It is my dream for our sales figures to be doubled by then. That is my goal for the future.

0 COMMENTS