Guided by its newly established corporate slogan – “Beyond manufacturing. Toward creation.” – Press Kogyo leverages its ‘product development capabilities’ and ‘production technology capabilities’ to contribute to society through manufacturing.

Can you please share with us a brief introduction to your firm? What do you believe to be your core strengths, or core competencies, that set you apart from your regional manufacturing competitors?

Our company is a manufacturer of automotive parts and construction machinery parts that will celebrate its 100th anniversary in 2025. We have three core products: frames, axles, and cabins for construction machinery.

Regarding automotive parts, as a pioneer of large-scale stamping founded in 1925, we started production of automotive frames in 1929, and in 1953, became the first in Japan to succeed in stamping a large rear axle housing. To this day, we have responded to the various needs of automobile manufacturers, including manufacturers of commercial vehicles, while striving to strengthen our technological and development capabilities.

Regarding construction machinery parts, we began producing cabins for construction machinery in 1977, making use of the knowledge we had cultivated in the production of automotive parts. Since 1999, we have been producing high-strength cabins for construction machinery that apply the variant shaped steel pipe technology developed by our company, and have been delivering them to many construction machinery manufacturers.

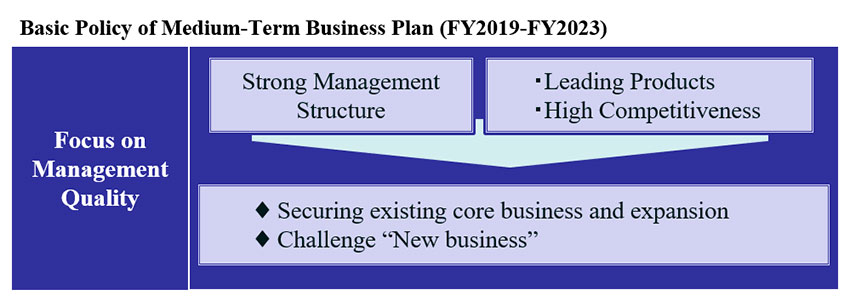

Currently, the automotive industry is in the middle of a once-in-a-century transformation due to the introduction of CASE-related technologies such as electrification and autonomous driving. Based on the Medium-Term Business Plan (five-year plan from FY2019 to FY2023), we have set a basic policy of “Focus on Quality Management,” and are working on initiatives for building a “strong management structure” and producing “leading products with high competitiveness.”

Before explaining our company’s strengths, I would like to talk a little about the premise of the industry to which we cater to. One of the characteristics of Japanese commercial vehicles is that they have a wide variety of specifications because the detailed needs of users are incorporated into the lineup of basic vehicles before they are sold.

In response to this, we produce frames and axles according to the specifications of each commercial vehicle manufacturer, therefore there are hundreds of variations, including in product specifications and component configurations.

As such, the products must be produced in high-mix, low-volume, but cost competitiveness, quality, and prompt delivery are also necessary.

Solving these conflicting issues is one of our company’s strengths, and this strength can be broadly divided into two categories: “product development capabilities” and “production technology capabilities.”

Regarding “product development capabilities,” we are able to design and develop products ourselves, so we collaborate with commercial vehicle manufacturers from the development stage and propose specifications. In addition, we have a variety of experimental equipment, such as vibration testing machines, and can conduct product analyses and experiments in-house.

As for “production technology capabilities,” not only do we have advanced stamping and welding technologies that have been cultivated over many years, we also possess the ability to manufacture dies and production lines in-house, meaning that we are always able to build an optimal production system. Moreover, our production bases are located close to our customers, therefore we are able to deliver directly to their production lines.

In addition to this, we have built a quality management system based on the certification and registration of public institutions, and are able to work on quality assurance activities from product planning and development to shipping and services.

The above is an explanation of our company’s strengths, but our “comprehensive technological capabilities” that allow us to consistently undertake everything from design, development, and testing to tooling for dies and equipment, production, and quality assurance in-house can also be said to be one of our strengths.

Underpinning these strengths are, of course, our human resources. In order to develop and strengthen human resources, we are working to pass on skills and improve expertise. Specifically, we are introducing a Meister system and working to improve our in-house training system in order to nurture the younger generation.

In addition, since the founding of our company, we have passed on the corporate culture of “Integrity and Effort.” These words are engraved on the stone monument commemorating the 60th anniversary of Press Kogyo’s founding, but they also permeate the actions of each and every employee. We believe that steady initiatives based on this spirit of “Integrity and Effort” are reflected in our products and services, which in turn leads to the trust of our customers.

Prime Minister Kishida recently described the Japanese demographic situation as being at a tipping point in many respects. Can you tell us a little bit about the impact that Japan's aging population is having for your company, and how you're responding to the challenges it may pose?

Regarding the decrease in the working population due to the declining birthrate and aging population in Japan, there are concerns about the impact of the shortage of truck drivers on demand for commercial vehicles. However, we believe that the first major challenge to address is the response to this decrease in human resources.

In order to deal with this challenge, we are promoting the construction of an efficient production system by automating the production line, developing multi-skilled workers who can work on many processes all on their own, and introducing AI/IoT while integrating it with manufacturing. In addition, we are working to review the personnel system and improve the workplace environment in order to promote the active participation of older people and women at manufacturing sites.

When we talk about heavy vehicles, that market is living a very transformative time in the switch to EV or from hybrid to EV. Again, we're seeing many faces to this change, including critically a change in materials to make these vehicles lighter and more fuel efficient. I'd like to know a little more about what the impact of the shift to EVs has been for your business, and how you're able to respond to these changing market needs.

With the shift to EVs in commercial vehicles, our core products consisting of frames and axles will not disappear, but we expect that their specification will change.

Regarding frames, we believe that it will be necessary to devise ways to change what is equipped as well as the method of equipment, such as by incorporating more batteries, as the power source changes from an engine to a motor. In addition, protective parts for batteries and fuel cells will be necessary to ensure safety in the event of a collision.

Regarding axles, we anticipate that there will be various changes in specification, but as the structure of an axle changes according to the layout of the motor and battery, we expect that the specification will vary depending on the customer.

Press Kogyo designs and develops products, and makes proposals to customers based on these changes and customer needs. In addition, since the vehicle weight increases due to the installation of the battery, we are also working to investigate and adopt new materials to reduce weight.

The challenge for making a vehicle carbon neutral, I think, is fundamentally different for a passenger car than it is for a container truck, or for heavy vehicles like mining machinery, for example. If you go home in your EV car and plug it in every night and charge it every day, you create a functional schedule, but for mining machinery that has to operate 24/7, or for a container truck that has to go long distances without charging, it's a fundamentally different challenge. How do you think that this shift to EVs can be brought to your type of client, to these heavy vehicles and heavy industry?

Although the conversion of commercial vehicles to EVs has lagged behind that of passenger cars, we believe that the switchover will progress gradually. We expect commercial vehicles to be converted to BEVs or FCVs depending on their use, and that the switchover will likely progress in full scale from the late 2020s.

As a company, we will accurately grasp this major transformation and, as I previously mentioned, respond flexibly to the changes in frames and axles accompanying the shift to EVs.

You have a variant shaped steel pipe technology used to make a very strong cabin for construction machinery to prevent accidents at the construction site. I was hoping you could tell us a little more about this manufacturing technology, and how else you are ensuring the safety of the people who operate machinery or vehicles with your components.

Firstly, I would like to briefly explain the variant shaped steel pipe technology. It is a processing method that aims for lightweight design, advanced precision, and high strength by eliminating the joint structure of the pillar of the cabin for construction machinery by integrally forming small and large bends in steel pipes.

This variant shaped steel pipe technology was developed in the 1990s at the Onomichi Plant (cabins for construction machinery are produced, from design and development to production, at the Onomichi Plant).

Press Kogyo has five production bases in Japan, four of which are in Kanto, and the Onomichi Plant is in Hiroshima Prefecture. I have personal experience working at the Onomichi Plant and I can say that, in a good way, it possesses a sense of freedom due to its location far away from headquarters.

Back then, there was a demand from construction machinery manufacturers to develop strong cabins for construction machinery suitable for ROPS structures (roll-over protective structures). In order to meet these customer needs, the young engineers at the Onomichi Plant worked independently to develop this technology, and made it a reality.

Unlike conventional pillars, pillars that use our variant shaped steel pipe technology do not require welding of joints, leading to higher strength cabins for construction machinery, and it has received high praise from construction machinery manufacturers.

I'm really interested in the Onomichi site, where you talk about this creative space that's separated from the headquarters, that's a hotbed for new ideas and experimentation. Looking back to your earlier comments, you mentioned very briefly how you're starting to see some results from the integration of DX and new technologies in the gemba, or the factory site. I was hoping you could elaborate a little more on that. How have you incorporated new digital tools into your manufacturing process?

We believe that it is necessary to proactively and flexibly address changes in not only technology, but the times and society as well.

As an example of the use of new digital tools, with IoT, we can automatically capture data from each production facility and visualize the operating status (the captured data is displayed directly on the monitor at each site using a mechanism developed in-house). As a result, we are able to respond flexibly to fluctuations in orders from customers and reduce production loss on production lines for high-mix, low-volume production.

Moreover, we are working to reduce the downtime of production lines by incorporating AI to perform predictive maintenance for production problems. In addition, with RPA, we are improving work efficiency by robotizing work that had previously been done manually.

We will expand the introduction of digital tools not only to manufacturing departments, but also to staff departments, aiming to further improve productivity and operational efficiency.

You talked about having strong communication and collaboration both with your clients and customers, and also about having a history of collaboration with other manufacturers to develop technologies like the variant shaped steel pipe technology, for example. As many Japanese firms are shifting their focus overseas more and more, can you tell us the importance of finding these kinds of partnership opportunities with overseas companies for your business?

At home and abroad, we are always looking for new opportunities and possibilities. In our considerations, we believe that collaborations with other companies, including domestic companies as well as overseas companies, is a powerful option. However, when it comes to collaborations, we aim to consider appropriate methods and forms after clarifying the purpose and risks of the collaboration.

When expanding overseas into a new region, we consider the following three points: 1) whether two or more reliable customers can be expected (depending on only one customer is a high risk), 2) how low the geopolitical risk is, and 3) whether we will be able to secure competitive suppliers.

Is there a particular region that you're emphasizing, going forward, that you're putting forward as your focus as part of your international development?

Currently, we have five overseas bases (in the U.S., Thailand, Sweden, China, and Indonesia), but these sites were established based on requests from customers who wanted our products to be supplied locally.

In addition, due to parts supply constraints such as the recent shortage of semiconductors, customers are aware of the risk of ordering from one company and one site. We believe that this customer trend, along with changes in the business environment and product specifications accompanying the shift to EVs and FCVs, present an opportunity for us to expand our business.

For the time being, we will give priority to expanding our existing overseas sites, but we will also consider establishing new sites while taking into account requests from customers and the three points I mentioned earlier.

Let's say we come back to interview you again in seven years' time for your company’s 105th anniversary. What would you like to tell us about your goals and dreams for the company in that timeframe, and what would you like to have achieved by then?

Two years ago, in April 2021, after reviewing our company’s value and reason for being, we established a new corporate vision, mission and values, and formulated the slogan – “Beyond manufacturing. Toward creation.” – in preparation for our company’s upcoming 100th anniversary in 2025.

This corporate vision declares that “With pride and self-belief, we will continue to grow together with our stakeholders as a positive presence in our society.” These stakeholders include customers, suppliers, employees, shareholders, local communities, and the global environment.

My goal and dream is that in two years when Press Kogyo celebrates its 100th anniversary, in seven years when it celebrates its 105th, and beyond that into the future, we will continue to be a company that grows alongside its stakeholders and contributes to society through manufacturing.

To that end, in order to solidify the foundation for this goal and dream, I would like to improve the quality of all aspects of management, including not only products, but also operations, administration, and contracts, based on the basic policy of “Focus on Quality Management” under the current Medium-Term Business Plan.

0 COMMENTS