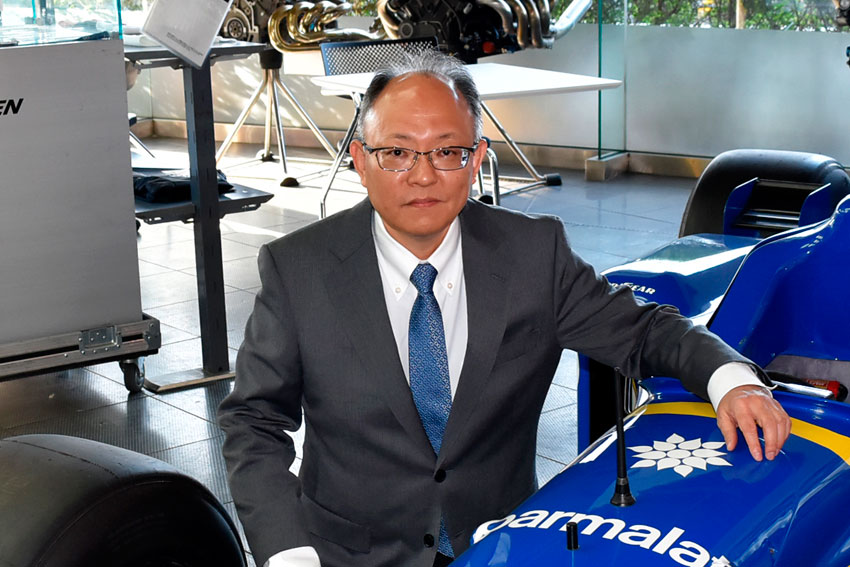

Founded by the son of the founder of Honda Motor Company, Hirotoshi Honda, MUGEN was established in 1973. Since then, they have been working closely with Honda Motor Company in co-creation, research and developments of engines, vehicle parts, and accessories. Mr. Hashimoto took over as the President of M-TEC Co,. Ltd. (Current company name herein after referred to as MUGEN) 2015. We talked with him to further discuss MUGEN’s background and developments in response to the current trends.

In manufacturing capacities, there are four elements that are necessary requirements: high-precision machining, controlled environment, CAD & CAM Software, and qualified engineers. As a high-precision manufacturing company, how do you integrate these four elements, and what are the roles of engineers?

We have all the elements that integrate with each other in our factory here on a 24/7 non-stop basis. We do have data engineers that run and operate the manufacturing process and perform design of CAD & CAM system. We utilize the roles of engineers from a design point of view, where it is a crucial trigger point for our company. We conduct regular interactions with Honda’s Research and Development division to respond to their demands on what kind of modification parts they need.

Another important point to take care of is quality control. It starts with the raw materials to the production lots. The accuracy of measurement needs to be precise on 1/1000-millimeter-scale in our manufacturing process for a special request from customers. F1 engine parts which brought several championships to us and Honda were also manufactured here. We are capable of boosting the level of satisfaction for customers based on our previous experience. Though we have already received high customer satisfaction, we always review our finished products through inspection data and look for areas for improvement to create better products.

What do you think are the key technical development in MUGEN’s history that brought the company where it is today?

MUGEN has three major activities in the company since it was established in 1973. Of course, with the course of time, there are changes of environment and market demand, however, we do still keep our company’s strong philosophy. Our company will continue to be a manufacturer that makes good products. We are not changing any policy in our business divisions, as they are complementary to each other and are irreplaceable. As an example, when we design racing car parts, we are not simply producing them, but we also assemble and represent our racing cars under the name of TEAM MUGEN on the circuit.

Honda Racing in the USA and Japan is one of the racing parts that we produce. Honda is developing and actively participating in different racing competitions and we have a very close and crucial connection with Honda, as our racing parts are very important to increasing the competitive side of Honda.

Could you tell us about the co-creation between MUGEN and Honda?

The main part of our business is modification and designing of existing parts for racing purposes.

There are several parts including carbon body parts and engine parts we collaborate on to ensure race victories. We also provide engines and engine circuit support services for Honda NSX teams. We believe such collaborating activities contribute to the victory of Honda.

How important are MUGEN Motorsport parts to the sale of MUGEN car parts?

MUGEN Motorsports is heavily related to our branding and marketing activities for the sales of car parts. We also have what we call the Shinden Project in which we participate in THE ISLE OF MAN TT RACE ZERO TT. This project has the purpose of showing our research and development stages in racing car components. We are working on this project totally independent of Honda.

Could you highlight the competitive advantages of MUGEN in comparison with Nissan’s Nismo and Toyota’s TRD?

First of all, the connections of these companies to their mother companies are an example of an injected capital from satellite companies dependent on the shares. At some point, MUGEN’s capital or share is established with Honda, however, we are an independent company from Honda so then our business decisions can be made quickly.

The trends of die casting metals to create engine blocks and transmissions are changing the way car components are made. In addition, iron and steel transitioning to aluminum and magnesium has also become a trend. How does MUGEN respond to the trends?

Before we get to the point of the introduction of lightweight materials, we installed the 3D printers that are able to deal with new types of materials. In that part, we are trying to innovate. To sustain this balance, we introduce certain innovations to lead the market investment. We need to get along with the trend and forecast the future in terms of technology and being profitable from the equipment. We look forward to what kind of materials and equipment can actually go in line with the trends.

In your case, you focus on very niche high-performance products. What are your responses to the shift into automated car production processes?

In some way, we already have semi-automated production lines that run 24/7. In that matter, you can call our company one that uses automation technology. Having the equipment that runs semi-automatically in the production lines, does not mean that we do not have the manpower in the operation. As a CEO who has a technical background, I do have an interest in equipment and I believe that there is part of philosophical aspects in each piece of equipment, meaning no matter how advanced the automation technology, it still needs engineers to make sure the operation is in a proper way.

As someone who came with a research and development background, what are the main priorities of your R&D department?

I was in Honda’s R&D department for 28 years working with so many engineers. We can see how Honda prioritized it. Since moving to MUGEN, there has been a lot of changes in my perspective and attitudes towards the R&D. Visualizing the final and target outcome is beneficial in many ways. Focusing on every step to make the goal happens while increasing the speed of production lines and increase the functionality is what we do. We do have those people who are deeply passionate about researching and developing our products to strive in reaching the goals.

Which field does MUGEN put priority on?

It is EV business. We won THE ISLE OF MAN TT RACE ZERO TT with our own developed EV motorcycle, Shinden for 6 times. Now EV Motocrosser, “E-REX” is taking over technologies accumulated thorough the Shinde project – compact but high-output motor technologies developed through the project so unique that other makes cannot have. The motor has the highest output: 120kw and the maximum torque is 210nm. Without losing its performance or cooling capability the motor was developed in a quite limited space of the motorcycle. At the same time weight-saving was achieved and reliability was ensured. Such a motor was combined with an inverter into a much smaller power unit for the motocross. The power unit is resistant to water, mud, and a certain amount of impact. In fact, the package has been revealed at a demonstration event. The power unit we developed has been utilized under various environmental situations and can be adopted for both two- or four-wheels vehicles in any harsh conditions. Our highest priority currently is electrification of the motorcycles and cars, which is regarded as a global trend that believe our customers are also expecting from us.

When we talk about EVs, there are problems related to battery weight, longevity, and performance. Do you think this problem can be solved from your perspective as an engineer?

In my perspective, there will be no drastic changes in the EVs. But what matters most is battery performance installed in EVs. Since battery power is generated by chemical reaction, there still is space for improvement of performance somehow.

Could you tell us your midterm goal strategies to take advantage of the growing aftersales market?

I do agree that the availability of aftersales products is around the global market. In terms of the strategic plan of the company, we are thinking of mobility as a method of transportation. For that, we are expecting to open a new branch in the near future serving the better needs for mobility.

Also, we are thinking about specifically tailor-made customized parts in advanced economic countries that aim to shift into 100% electronic vehicles. Electrification might be as good as what we think, however, when we talk about the digitalization of watches as an example; traditional watches are sold at a very high price compared to digital watches. This situation can relate to vehicles, where conventional cars will still be needed, as there will still be a solid customer base.

Aftermarket parts are currently expanding into electrification. Some people do not only buy a car for its initial purpose as transportation, but also something they can modify to have exclusivity, as is human nature. For that, the EV modification trend is apparent on the market right now. We believe it will expand more in the future and we will provide those people with the modifications that they need.

Do you believe, in the future, conventional vehicles will still be in the market for those who are nostalgic about them, and do you think it will be still an important sector for your business?

I believe it is true that conventional vehicles will be nostalgic for some people, and I am already feeling that currently. Even though these vehicles can be super expensive in the future, I believe I will be still driving combustion engine vehicles. We are now developing 2,000cc V-Twin motorcycle engine. We are certain that engine lovers will surely like it. We believe it is only because MUGEN has less than 200 employees that it is able to produce both EV and large-size gasoline engines. For us both the EV market and gas engine market are important and we are always ready to provide good products for both markets.

Could you tell us how important the overseas market is to MUGEN?

We have headquarters in the UK and a sole distributor in the US. The reason behind that is we do have a goal in these markets; however, it is not our main focus right now. Besides the European and US markets, we are thinking of expanding our operations in China and Southeast Asian countries. Ideally, we will be opening overseas branches or local suppliers in these countries and we are currently brainstorming the best ideas for that. Indonesia and China are two locations where we have the greatest progress, in terms of local suppliers.

What would be the strategy to penetrate the Chinese market, as it would be hard for overseas companies to get into?

It is true from a political and economic perspective. One way to overcome this would be having local suppliers that we can trust and lead us to the final goal. If need be, we can also send out our members to China to understand this market.

In 10 years, where do you see the company at and what do you want the company to achieve proudly?

From a nation-wide perspective, Japanese national character has a high level of modesty and contribution collectively. The company needs to approach every single employee, as every one of us has a different specialty in skills, knowledge, and backgrounds. As a CEO of the company, I do believe that I need to be capable of extracting the best from each individual on a personal level to combine them into one mutual working force, without forgetting each individual’s personal goal. That is the ultimate goal for years to come and it will be ideal to make everybody happy.

0 COMMENTS