As it navigates new challenges and opportunities, adhesive company ALTECO is focused on expanding its presence overseas and also targeting products tailored for the electric vehicle (EV) market.

It is an exciting time for Japan specifically when it comes to manufacturing. The past three years have seen severe supply chain disruptions due to COVID as well as the US-China decoupling situation, and as a result, many corporate groups are looking to diversify their suppliers for reliability. Known for their reliability, advanced technology, and high-quality products, Japanese firms are in an interesting position, and due to a weakened JPY, many observers argue that this is a unique opportunity. Do you agree with this sentiment, and what are the advantages of Japanese firms in this current macroeconomic environment?

I totally agree with that sentiment. Large-sized companies that export products overseas are definitely benefiting from this current situation. However, many SMEs that do not export products are struggling due to the effects of global inflation. It is a tough situation for them, but fortunately, it does not apply to us.

Japan is the oldest society in the world with a rapidly decreasing population. The effects of this have been a labor crisis and a shrinking domestic market. What have been some of the challenges this demographic decline has presented for your company and how have you been reacting to them?

It is becoming increasingly difficult for SMEs like us to hire new workers. To address this problem, we have been actively seeking to hire professional workers over the age of 60, who possess specialized skills and expertise. We also emphasize team building within the company and organize social gatherings such as company trips to onsens and other destinations to foster bonding among our employees. We go on domestic company trips twice per year, and we travel abroad every five years. Recently, for example, the employees of ALTECO Chemical Pte. Ltd. in Singapore joined the employees of ALTECO in Japan for a party. Bonding through social gatherings is crucial to our human resources strategy.

One way SMEs have mitigated this labor shortage is by looking overseas to bring in foreign workers. Is that a strategy that is of interest to your firm?

While hiring foreign workers might be a useful strategy for sales staff, it becomes more challenging when it comes to our factory workers due to the importance of safety in our operations. We produce chemical goods, and therefore communication is crucial for ensuring safety. We need to be able to effectively communicate in Japanese with our employees in these critical situations. Hence, hiring foreign workers for our factory might present some communication challenges.

Depending on various factors such as the composition, applications, and disposal methods, adhesives have negative impacts on the environment. How are you making your products more environmentally friendly, and can you elaborate on some of the strategies that you are implementing to contribute to a more sustainable society?

We do not produce any products that contain volatile organic compounds that contribute to air pollution or have harmful effects on human health. Our adhesives utilize the moisture in the air, light, or the cutting off of oxygen for adhesion, and they do not require heat or energy for curing. We are very conscious of being environmentally friendly and prioritize safety and sustainability in our product development.

One specific product that you have is your Instant Adhesive. It is used by craftsmen as well as at cutting-edge production sites and it showcases and demonstrates adhesive strength within seconds of being applied. Could you go into more detail about its competitive advantages and what makes it superior to other adhesives on the market?

One of our strengths is customizing our products according to the specific needs of our customers, particularly in industrial applications. This allows us to develop new functions and enhance the performance of our adhesives, such as improving heat resistance. Our ability to tailor our products sets us apart from our competitors.

Is there a specific example that sticks out in your mind of a product that you created for a client that you can share with us?

Almost all of our products are customized, especially when it comes to automotive applications that have stringent performance requirements. Each time we collaborate with automotive manufacturers, it is a nerve-wracking experience to ensure that all the requirements are met.

The automobile industry is going through an interesting transition with the switch from combustion engines to EVs. The cars need to be lighter, and when it comes to components, we know that thermal dissipation is an issue as the battery and inverter create a lot of heat. How are you meeting that challenge, and as a glue maker, what opportunities has this transition to EVs presented to you?

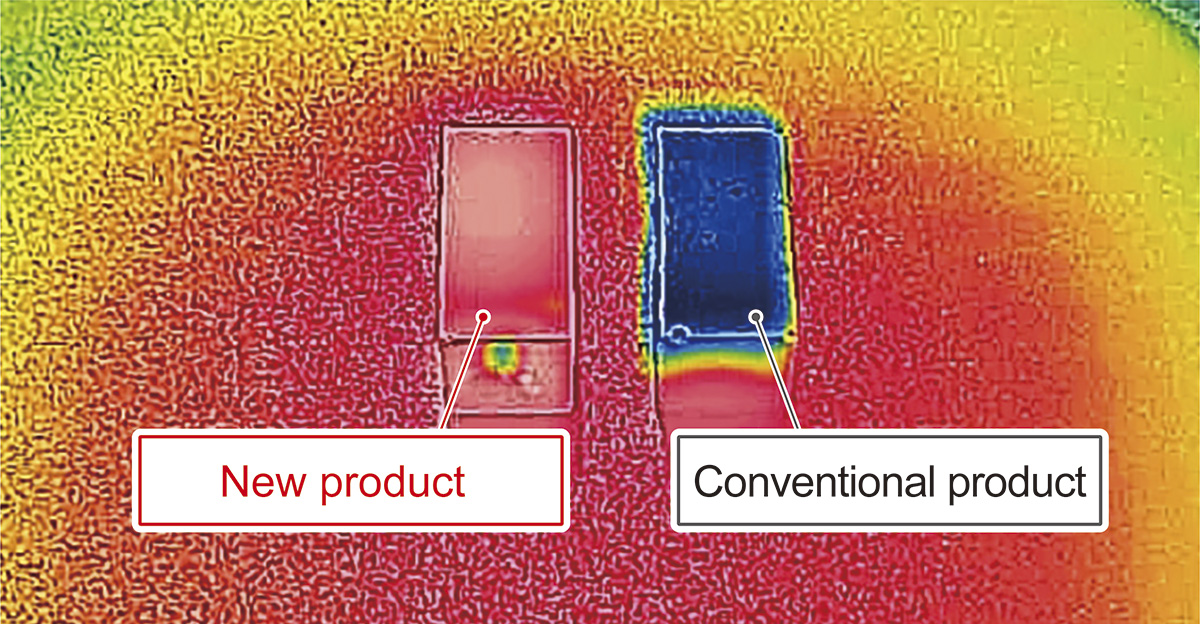

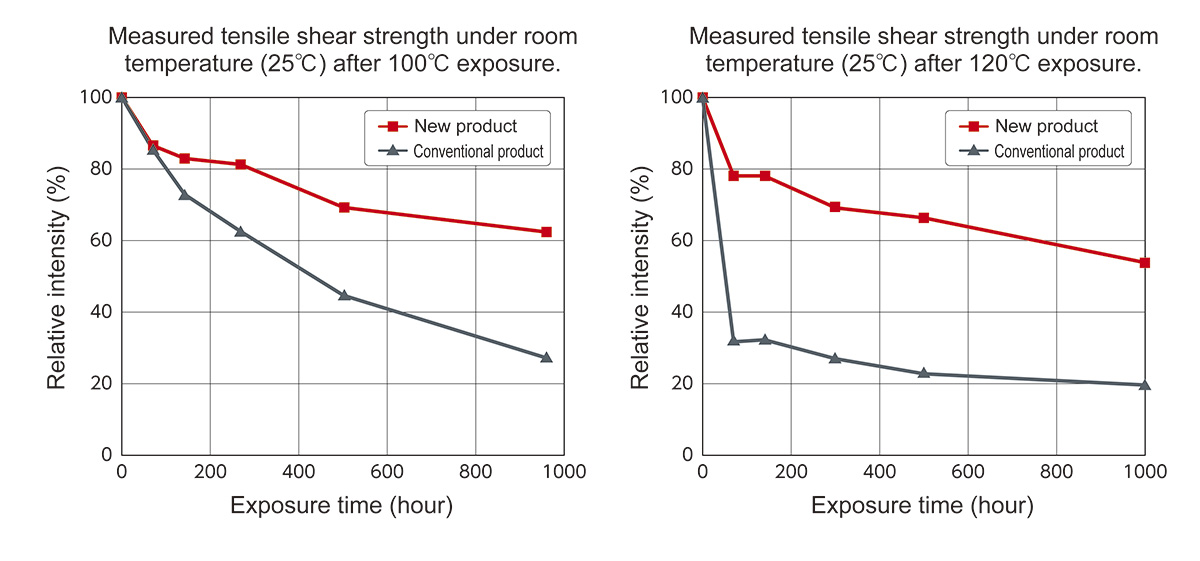

The transition to EVs indeed poses challenges, however, it also presents a great opportunity for us. One of our new products, which is two-part epoxy resin adhesive, is a heat radiation adhesive without the need for additional production equipment.

And more, we developed new instant adhesive with high heat and water resistance.

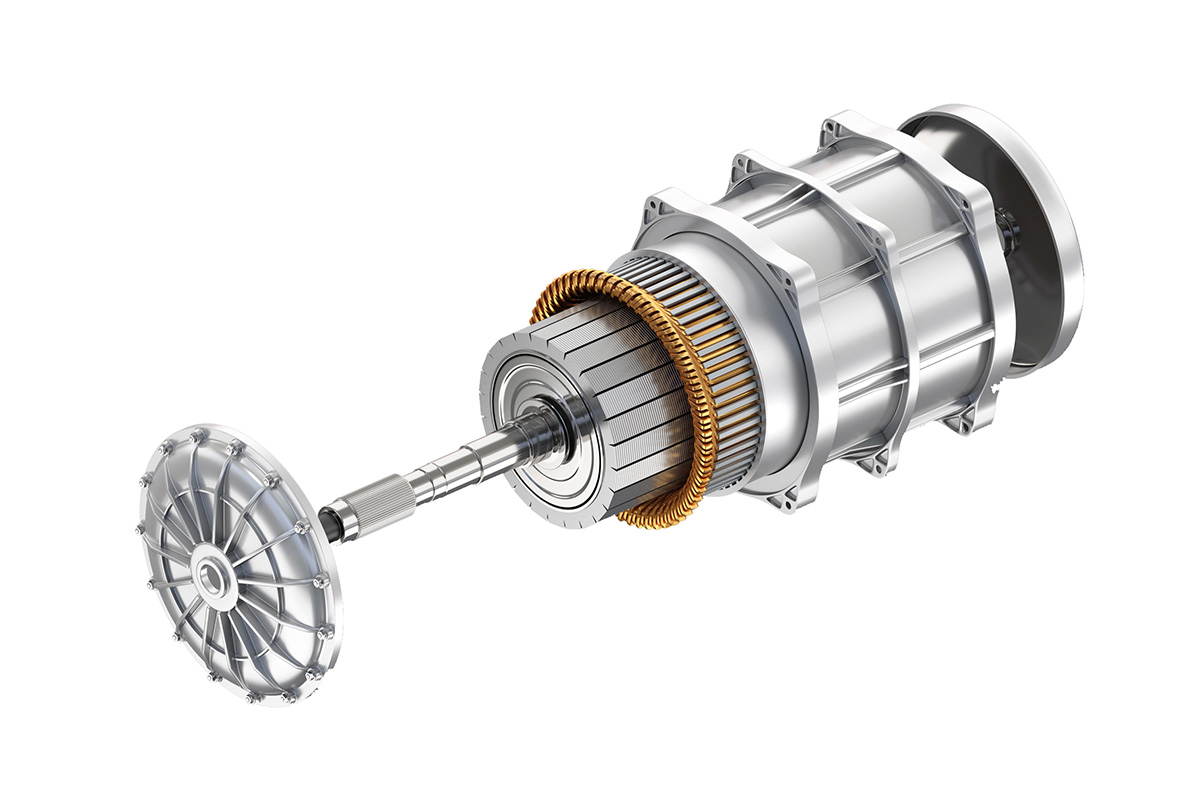

And now, we can provide suitable anaerobic adhesives for motor shaft, motor core, and motor magnet and so on. We believe these products will be of interest to EV manufacturers.

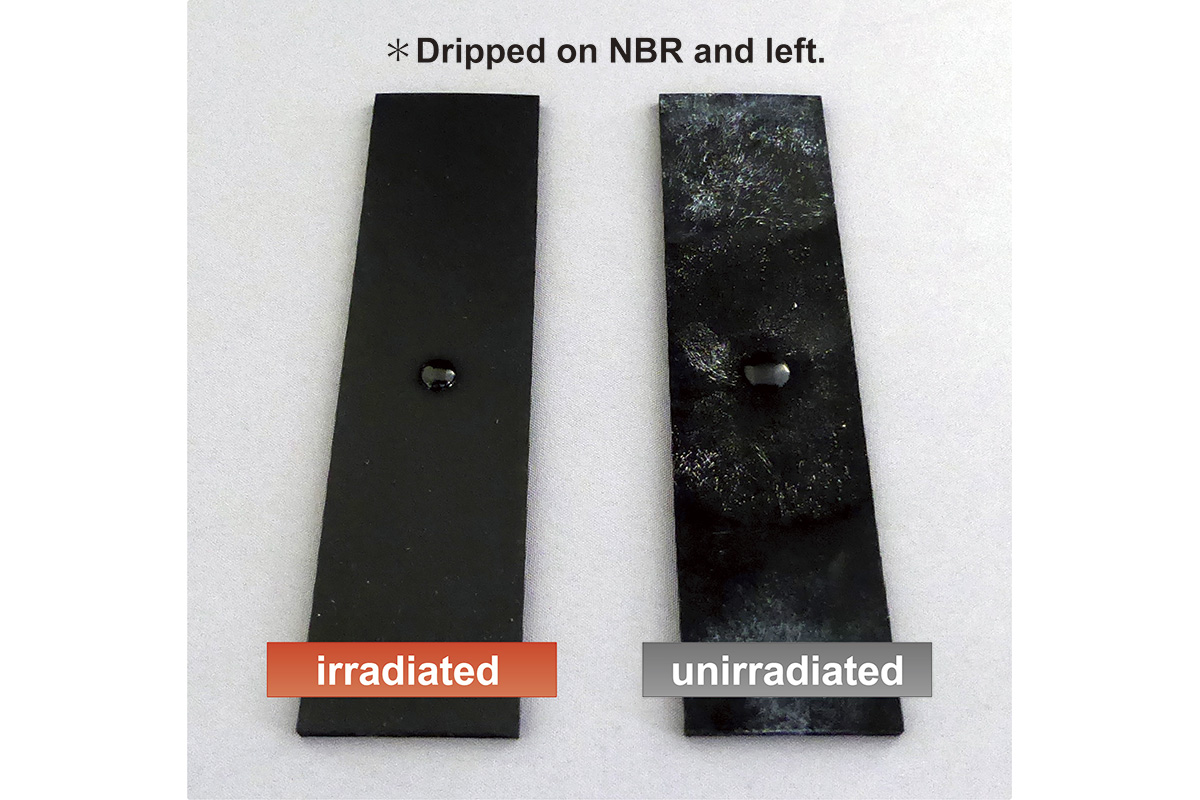

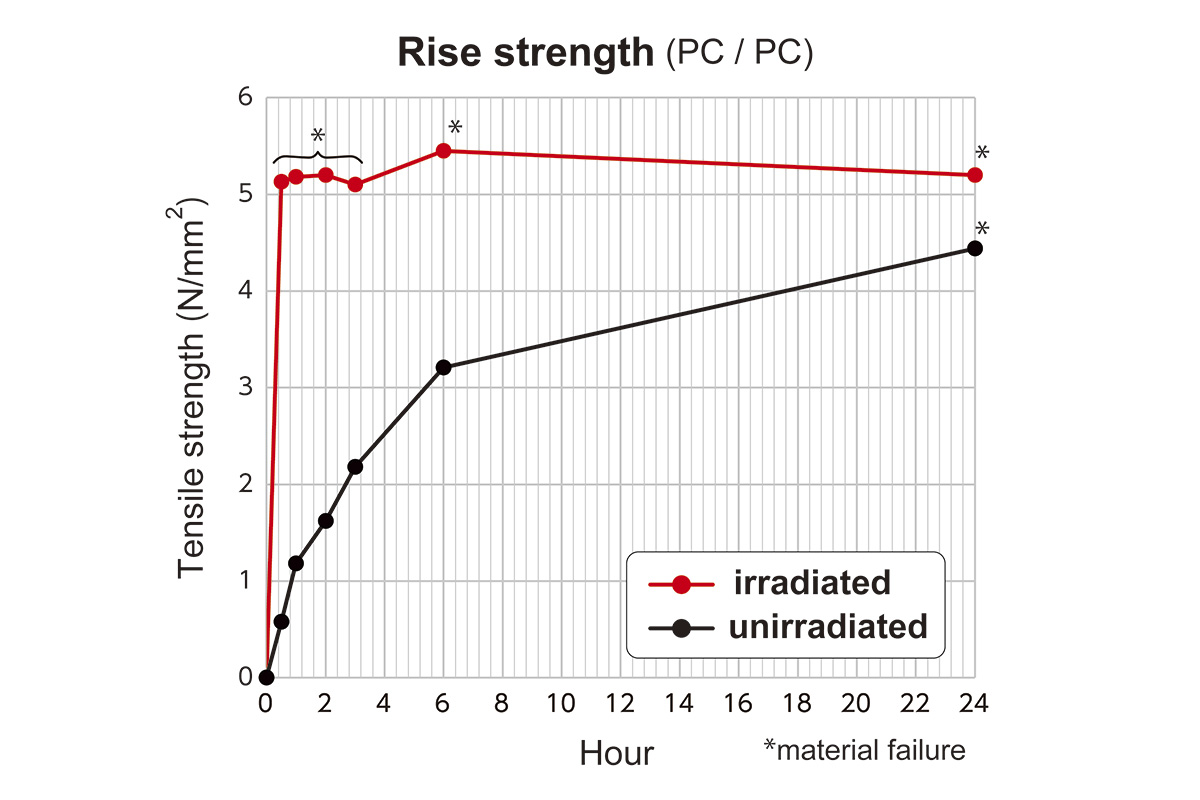

Another popular product of ours is our light-curable instant glue, which is an instant adhesive that has light curability. The curing is faster than conventional high-speed adhesives due to UV light irradiation. While it is conventional instant glue, through UV light irradiation, you cannot see the blooming. We believe that this is also ideal for EV applications.

Are you specifically looking to supply your products to EV companies within Japan or also to overseas companies as well?

We will look to work with Japanese manufacturers first. However, in the near future, we will begin to look for overseas manufacturers in China. The support of our customers is vital, and we have been proposing our new products to them. These products have innovative features such as heat resistance, UV irradiation, or high transparency for example. Providing these innovative features is an important part of our R&D strategy.

How did you overcome the logistical issues that COVID caused to supply chains over the past three years?

During that period, we saved our overstock for our customers. That was our risk and not the customers’ risk. Many Japanese companies did so.

Is the final application more B2C application or B2B application?

It is almost entirely B2C except for the Japanese market.

One area that we were interested to hear about was your expansion to Ghana in 2013. Many Japanese companies that we have interviewed have not been to Africa at all and are only now starting to turn their attention to that region. For your company, it has been 30 years since you entered that market. What are the lessons that you have learned from your experience in Ghana over the past 30 years, and how will you apply that to your international business going forward?

In ALTECO Group context, ALTECO Chemical Pte Ltd plays the core role of our business globalisation goal. From Singapore, they export ALTECO products to about 20 African countries. Of these African markets, the shipment time to West Africa is the longest, taking about one month to reach destination port. Sometimes, up to two months. Adding in Customs formalities, it totals at least one and half month. This delivery time uncertainty often caused shortage of ALTECO product in the market. Hence, ALTECO Ghana, in Ghana, West Africa, was set up. Now, our key customers can receive goods as fast as within the same day, drastically reducing the delivery to receipt time.

Despite being an SME, ALTECO Group has vast experience in establishing physical operation in many countries, including Japan, the USA, Singapore, China, Indonesia, Korea and Ghana. For every new overseas establishment, we are always conscious of and pay special attention to the cultural differences. Ghana was no exception.

Having active exposure to the West African markets for more than 30 years, ALTECO Chemical Pte Ltd gained vast knowledge of their business and people culture. Establishing a physical presence in Ghana enhances this knowledge. Giving us direct access to end-users in West Africa region and allowing us to speedily adjust/adapt to their needs. Hence, opening up more business opportunities.

ALTECO Group

We hear from many Japanese companies that they would like to expand to Africa. Your company has been operating in Africa for more than 30 years. Could you tell us why your glues are so well received in Africa, and why have you been so successful in that market?

As I mentioned earlier, ALTECO Chemical Pte. Ltd. in Singapore plays a core role in our overseas expansion. Singapore company, like Japanese company, is known for its integrity and seriousness in business dealings.

Combined with the fact that Singapore is a multiracial, multireligious, and business-oriented society, it helps bridge cultural differences with business partners from different regions.

This advantage makes it easier to deal with potential partners and boosted our business venture into Asia, the Middle East and Africa.

Selling good quality super glue in Africa market may sound a mission impossible or unimaginable uphill task to many. However, unknown to many, African consumers in general do appreciate good product at reasonable price.

African consumers are often dumped with inferior quality products without any alternative choice. ALTECO offered that alternative. Coupled with working closely with our African partners and constant consumer education, ALTECO achieved success. Focus and hardwork are definitely necessary.

You are also present in other locations across Asia such as China, Korea, and Indonesia. What other countries or regions do you believe are key for your corporate growth?

Our immediate focus is still on Africa. However, we are open to exploring opportunities in other regions as well.

Are you looking for new partnerships and new clients from overseas locations that you could work with to create new products?

While our distributors play a crucial role in stocking and delivering our products to end-users, particularly in Asia, the Middle East, and Africa, there are some exceptions. Occasionally, we supply the liquid contents of our adhesives to other manufacturers who then utilize it to produce the final adhesive under their own brand. This arrangement allows us to expand our reach and presence in various markets.

In terms of our focus, we are actively seeking new partners, both domestic and overseas, for our industrial applications, rather than our consumer applications. Although our ALTECO brand for consumer applications has successfully penetrated markets in Asia, the Middle East, and Africa, we recognize the need to further establish our presence in the industrial applications market. This presents a key challenge for us, and we are eager to pursue new collaborations and opportunities to achieve this objective.

Your company was established and incorporated in 1969 and since then you have become a specialized manufacturer of adhesives for both B2C and B2B applications. Could you run us through some of the key milestones in your company’s history that have allowed you to be so successful and helped to get you to where you are today?

When ALTECO was first established we faced many challenges. My father was the founder of ALTECO. However, he initially struggled with Japanese domestic market expansion, and therefore wanted to explore overseas markets. My mother who was proficient in English wrote to 300 potential overseas companies to promote the ALTECO brand and products. This initiative paid off and led to new business opportunities which laid the foundation for the company’s international expansion.

ALTECO’s success can be attributed to our “frontier spirit” and our ability to overcome challenges. This resilience and determination have been instrumental in exploring new markets such as Africa, and continuously adapting to meet the evolving needs of our customers. By constantly innovating and developing new products, we have remained competitive and continue to be successful in the market today.

We saw that 1980 was the year that you began your overseas expansion. Has the overseas market grown since then for you and what percentage of your sales does the overseas market account for today?

As I mentioned earlier, ALTECO Chemical Pte. Ltd. in Singapore has been instrumental in our success in Asia, the Middle East and Africa. Their natural unique expertise has facilitated our expansion and networking efforts in those regions. While we Japanese may not have as extensive connections worldwide, leveraging the strengths of ALTECO Chemical Pte. Ltd. in Singapore has enabled us to gain a foothold in these markets

If we were to return to interview you again in six years, is there a personal goal or ambition that you would like to have achieved?

While we do not have a concrete plan such as an M&A or building a new factory, we aim to transition from being solely a specialized instant adhesive manufacturer for consumer applications to becoming a well-regarded adhesive company for both consumer and industrial applications.

In Japan, we are already making progress in that direction as we do both industrial and consumer business. However, when it comes to overseas, our subsidiaries are lagging behind and only do B2C business. To achieve our goal, we must consider all options and adopt effective measures. That is my goal for the future.

Interview conducted by Karune Walker & Paul Mannion

0 COMMENTS