A detailed look at the cutting-edge technology developed by Japanese company, Logic and Design Co, revolutionizing image enhancement in various fields such as aviation, medical, surveillance, and disaster prevention.

We think that Japan is at a very interesting time right now, given the supply chain disruptions caused by Covid-19 and the tensions between China and the US. Coupled with the fact that the JPY is very low at this time, we think that Japanese products on the global scene are very attractive once again. Do you agree with this premise, and what would you say are the key advantages of Japanese suppliers within this macro environment?

Frankly speaking, our company is not yet in the process of becoming globalized. While overseas expansion is essential to us, establishing direct relationships, especially in the medical device field, is difficult. Therefore, we want to continue focusing on our existing partners who have their own global operations and leverage their supply chains to act as reliable suppliers to them.

Our company’s uniqueness lies in the fact that the average age of our employees is 55 years, meaning we are mostly from the senior generation. We also only have 19 employees at the company. Many of these employees have worked in multinational companies and have chosen our company for their second life after retirement. They want to challenge the world again with "Made in Japan" products. That is the mindset behind this company. Mr. Kitano and I worked for multinational companies for more than 20 years, which is how we know the business so well and how to deal with people in our field. The experience and knowledge we have allow us to take a shortcut when doing global business.

You mentioned the importance of partnerships and how developing solutions for the medical field is entirely different from the monitoring and surveillance field due to the different restrictions and regulatory frameworks required. For example, you have a development history with partners in China and Taiwan. Could you explain to us in more detail the role that partnerships play within your business model, and are you currently looking for new development partners in the different fields that you are working in?

We have two strategies in terms of partnerships in our global approach. The first is to partner with trading companies and sales agents. The second is to have direct business with global medical partners. We know who the major global players are due to our background working in these fields and have already established good relationships with some global medical companies. Our strategy is not to expand our company by hiring new employees. Instead, we want to limit the number of our employees and expand through partnerships. The advantage of having employees from the senior generation is the networks and knowledge they have accumulated over the years.

Japan is currently struggling due to its declining population. One solution to this problem is to utilize the more senior generation as a capable resource that can sustain the Japanese economy. The reason why we were able to gather so many experienced employees from the senior generation is that we have technologies that we are proud to grow. Currently, there is a global trend for AI image processing. However, AI image processing presumes and creates what AI imagines rather than what has actually happened. Our technology, on the other hand, is based on real-time occurrences and is not presumptive. In the medical field, 3D heads-up surgery has highly evaluated our technology for real occurrences. It has only been around one year since we entered the field of ophthalmology. However, we are highly recognized for providing unprocessed real-time images, and our technology has been utilized in electronic medical records.

We know that your company caters its products and software to various industries from disaster and crime prevention to the security field and medical field, as you have just mentioned. You count among your clients some very famous names such as Senju Pharmaceutical, Nipro, NEC, and Canon Marketing Japan, for example. Of the different industries that you are catering to, which one do you see as having the most growth potential from a business point of view, and are there any other fields or businesses that you see your technology helping in the near future?

The security field has a lot of potential for the future. Security cameras are ubiquitous now. The disaster prevention field also has potential when it comes to monitoring rivers and the ocean, for example. Other important areas where we can apply our technology are factory automation, drones, and AI. Medical devices and life science, including culture and entertainment, will also continue to be key areas for us going forward. There are many fields in which our technology can be applied. Deciding where to concentrate our efforts is the challenge at this time.

Which area would you like to focus more on in the coming months or years?

All the markets I mentioned are growing. We want to focus on consolidating our positions within those markets.

The range of brightness that a camera can detect is called the dynamic range. Many so-called unclear images are due to a narrow dynamic range. To help overcome this challenge, you developed your LISr® technology, which helps the camera better record the image. For example, your LISr-101 has a wide range of applications from helping to record in bad weather conditions to overcoming different luminosity and reflection issues. Your nano LISr® helps to further visualization under night vision/low contrast conditions for monitoring rivers, oceans, and construction sites where analog methods are still the mainstream. Can you introduce to us in more detail the exceptional features of your LISr® technology and the different fields and applications it is useful for?

This is a picture of weak exposure due to reverse lighting. Usually, you disassemble the image by dividing it into an extremely small grid to adjust the contrast of the image. However, the joining of the grid is adjusted differently. Since the frame is synthesized, it then has to be joined together with the grid image. This can take time to process and becomes heavier in content volume. It is called histogram equalization. Almost all of our competitors use this CLAHE method. However, they are still hazy, and it takes time to process. The range of brightness is from 0 to 255, with 0 to 50 being too dark and the highest levels being too bright. Using our technology, we first analyze the image and then process it down to the very minute pixels. We then optimize the contrast through the means of a histogram.

We have received a patent for this technology. No company can match our latest technology as we can process this type of rigorous lighting image with a latency of 1000/4. The data itself is already there. We are just making it more visible. We do not add to the image or presume what is there. We take the real image and flatten the histogram to achieve a more visible image. The fundamental difference between AI and our technology is that AI focuses on creating visible images through presumption while ours uses the actual data that is embedded. Our technology brings that data out. Photos that use our image-sharpening technology are recognized as concrete evidence in law cases.

LISr-101

Your LISr® technology is one of the two pillar technologies your company uses to expand visibility. The other is a very innovative technology called Re:Na® that helps recover images and footage that have experienced quality deterioration due to causes such as being out of focus, of low resolution, or shaking. This technology involves decomposing the image and recalculating its frequency until you reach the optimal output possible. Could you provide some insight into the key processes involved in decomposing and recalculating the frequency of the original image to achieve high-resolution restoration?

The biggest difference between AI image processing and our technology is that AI needs to go through machine learning to understand what needs to be recognized. For example, when it comes to factory automation used by a lens manufacturer, the AI cannot recognize the image if it is too dark. However, by using our technology to enhance the image, the AI can recognize scratches or inconsistencies in the surface treatment. We provide a high-quality resolution that AI can recognize.

Conventionally, in the field of ophthalmology, doctors used AI processing for images taken of the patient’s disorder. However, the visibility of the images was low, and it took the AI a long time to recognize the images. By using our technology, there was a case where the visibility was increased by more than seven to nine points, which converts to approximately 10%. Our technology can instantly sharpen and make thousands of images visible at once. If we were not a venture company partnered with a major medical company, this technology would surely be massive. It is still in the infancy stage. However, more and more physicians are recognizing our technology, and there has also been an academic paper written on our technology. Going forward, this technology will surely continue to spread both in Japan and around the globe.

Which areas can it be applied to in the medical field?

It can be applied to many areas such as monitoring patients, overall surgeries, neuro-related analysis, veins, cardiology, and so on. It can also be used for X-rays. It makes the data that exists in the dark areas of the image more visible.

Is this technology applied to real-time pictures?

There is a real-time processing device that is put between the camera and the monitor. The sampled photos can be processed by installing our software on PCs. Also, as I mentioned, our technology is used in electronic record-keeping in the medical field. This is done in real time with the patient.

Are there any limitations to this technology that you are currently trying to overcome? What are the challenges you face regarding this technology?

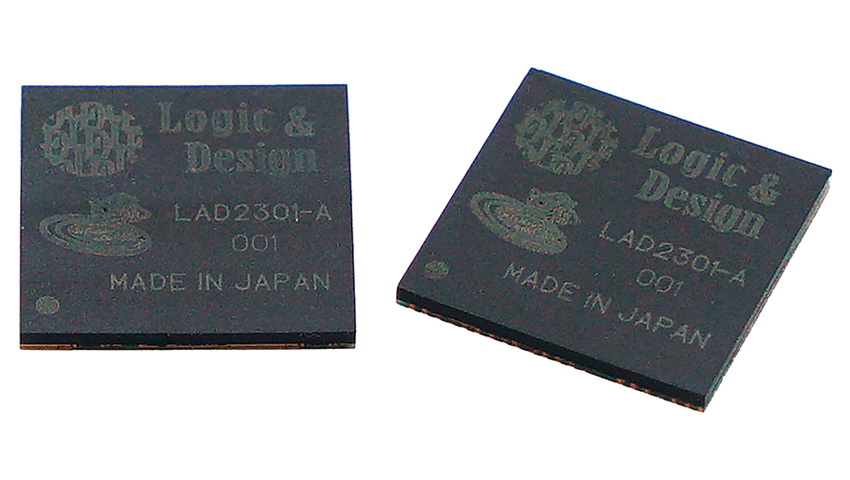

We have incorporated our technology into chip form so that it can be embedded into cameras. Once we can mass-produce these chips, there are infinite possibilities when it comes to increasing the capabilities of the camera controls. However, we still need to determine the user interface. There are also many new fields to which it could be applied. The new type of chip that we have developed is in an ISP semiconductor format that can be embedded into devices for real-time processing.

One issue that we faced was related to crime or surveillance cameras and drive recorders. The data that the camera takes is compressed to reduce the amount of data to be stored. However, even using our technology, this compressed data can be difficult to decompress and make more visible. To tackle this issue, we came up with the idea of embedding this chip in real-time network cameras so that we can have a clear image while still reducing the amount of data.

ASIC (LISr-ISP)

We place our chip on the second layer of the module when it comes to small-sized cameras. By integrating a chip, neutralization, and low power consumption can be achieved. With that, we can embed our technology in multiple applications that use small-sized cameras such as drive recorders, surveillance cameras, or in-vehicle cameras. We can also embed our technology in IP cores for smartphone SSDs.

One of the new types of applications that we envision is a smart eyeglass for people with poor vision. By having a camera with our chip on the eyeglass, real-time data could be processed. Another usage relates to surveillance cameras. Generally, you have a separate light pole for the lights with the surveillance camera being separate. However, we can miniaturize the camera with our technology so we envision placing it on the light pole and having no need for voluminous surveillance cameras anymore. We also want to apply our chips to cameras that are used to search areas that have been affected by natural disasters as these areas can be dark and difficult to reach. A new type of robot in the shape of a snake is used. By having cameras with our technology in each of the joints, these robots can move and search in the darkness more freely.

When do you plan to mass-produce and sell those types of products?

We are currently in the process of finding a partner. However, 2025 is our target for the mass production and sale of these products. When it comes to the medical field, we are currently pursuing the usage of this technology for endoscopic and microscopic applications.

Furthermore, we can create sensors through ISP implementation, and that is something that we are also pursuing. They will use the most recent generation algorithm with high speeds of 60 frames per second and high-quality visuals. These sensors have never been on the market before. We have been developing them, and the first sample will be available in February with the second sample being available later this year. In 2025, we will begin mass production. Right now, a Chinese company and a Japanese company are collaborating on the development. We have asked TSMC to use it. However, the final stage of production will be done by a Japanese company, so it will be a “Made in Japan” product.

It is amazing to see all the technology your company has been able to develop in the six years of your company’s history. Could you please tell us about the creation of the company? What motivated you and your 19 employees to enter this field, and what do you envision for the future of the company?

Our technical head is Mr. Kobayashi in Kobe. He was originally a game software developer. Twenty years ago, he established his own company. He became proficient with hardware through his experience at games centers. He also has extensive knowledge of the optical and communication fields. He is a genius. Mr. Kobayashi was contacted by the operator of a nuclear power plant located near the Sea of Japan. The weather conditions were so bad that it was difficult to fathom the surveillance camera data. As it was located at the sea, and people were coming in and out, it was very important to survey the situation. They asked Mr. Kobayashi to create an algorithm to enhance the images. He then developed the very first technology to do so in Japan. I met him around eight years ago. His background is in engineering while I am more from the marketing and business operation side. We decided to join together. Many of our people including myself have a background in the medical field, so we decided to apply this technology to the medical field.

(Mr. Kitano added the following):

I joined the company three years ago. When I met with Mr. Sato, he explained to me how realizing this technology into chip form would contribute to the world. This made me very determined to join the company. Many of our employees, including myself, are very passionate about the huge possibilities that our technology has. That was what inspired them to join the company. I have taken the lead in acquiring financial support and funding from farmers and other entities that I had a relationship with in the past. This has allowed us to start our development procedures to convert our technologies to chip form. We can assure you that if we can acquire more investment, we will be able to create more advanced products that can contribute even more to the world. We are a technology development company. However, the development of semiconductors is done in USD. The depreciation of the JPY has therefore been a disadvantage to our company.

0 COMMENTS