Japanese industrial robots have been transforming the way industries work and operate, leading to enhanced efficiency and providing a remedy for a declining domestic labor force

Navigating unfamiliar airports can be stressful, with exhausted passengers often struggling to find boarding gates, ticket offices, toilets, the correct luggage belt, or more seriously, a medical center or police station.

For travelers using Tokyo’s Haneda airport, help is at hand, in the form of 90-centimeter-tall humanoid robots being trialed there by Hitachi Ltd.

Linked to cameras around the airport and using artificial intelligence, the robots started work in early September, answering passengers’ questions in Japanese and English and, at speeds of up to six kilometers an hour, escorting them to their destination. They avoid collisions, even with moving objects appearing from blind angles, and are able to stand up unaided if knocked over.

Welcome to the rapidly evolving world of Japanese robotics.

While robotics has long been used worldwide in heavy industry like in auto assembly lines, they are also being used in a growing range of sectors, including in electronics manufacturing, chemicals production, for surgical procedures and the catering sector, as well as in driverless cars.

“Until now, the main goal pursued by robotic makers was to cut the cost of human labor,” says Eiji Takagi, President of the Tokyo-based Robotic Biology Institute (RBI).

“Today the approach has changed. Robotics efforts go beyond simple labor cost reduction and focus on creating more sophisticated human-type or human-designed robots that can add further value to production processes.”

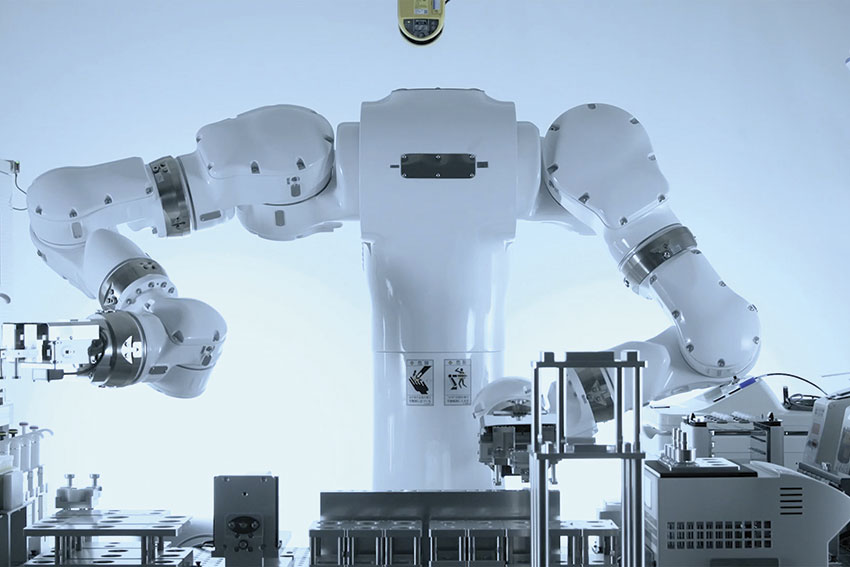

RBI is working alongside the long-established robotics company Yaskawa on the conception of Maholo, the world’s first humanoid robot used in life science and bio-industry research.

Maholo, by doing experiments previously done by humans using the same laboratory equipment and devices without modification, contributes to freeing up scientific expertise

“We want to make robots that are able to achieve things just as humans do–the same kind of tasks that humans can also perform. In the future we will see robots increasingly contribute to the industrial world, and touch more and more industries,” says Mr. Takagi.

Japan has long been big in the world of robotics. In 2015 it was second-placed in industrial robotic automation, according to the International Federation of Robotics (IFR), deploying 314 units per 100,000 employees.

This put it behind South Korea, with 478 units, and ahead of Germany, with 292 units. At 164 units, the U.S. is seventh, said IFR, which puts the annual international market value for robotic systems at $32 billion.

Average global robot sales rose 17% annually in 2010-2014, with China further expanding its leading position, accounting for 25% of total demand in 2014.

“With their digital interfaces, industrial robots can be seamlessly integrated into the networked structures of smart factories,” says Joe Gemma, President of the IFR.

“Robotic workers will in future be found working hand-in-hand with human staff, helping to replace traditional, rigid production processes with flexible structures.”

RBI’s Mr. Takagi agrees, and takes things further. “Our ultimate goal is to free up scientists, transferring work that only highly skilled humans can do now to robots so they have more time to be creative and productive, and perform higher-value tasks,” he says.

This has major implications for pharmaceutical companies and academia, and “such type of automation can clearly contribute to the advancement of science in certain fields,” Mr. Takagi explains.

Maholo’s technologies, he says, are five years ahead of those of competitors, and only Yaskawa is able to supply these robots on a global basis.

RBI plans to exhibit internationally, and in the next three years will open branches in the U.S. and the U.K.

Japan has many robotics developers and manufacturers, some of them industrial powers like Hitachi, owner of Haneda airport’s humanoids.

Panasonic Corp. is also developing robots to guide people at stations and airports, and also agricultural ones such as tomato-harvesting robots, in response to a shortage of farmers resulting from an aging and shrinking rural population.

The robots will automatically adjust greenhouse humidity and temperature levels, determine if a tomato is ripe enough to pick, harvest it, and then check the quality before shipment.

They are being developed under a government-sponsored project to use technology to make Japanese farm products internationally cost-competitive after tariffs on most imported goods are removed under the Trans-Pacific Partnership free trade deal, Japanese news agency Kyodo reported.

Another is Mitsubishi Heavy Industries Ltd. which recently unveiled Sakura, Japan’s first mobile inspection robot able to operate in high concentrations of explosive gases.

“As we may encounter accidents such as collisions involving hydrogen cars or a truck loaded with hydrogen tanks rolling over inside a road tunnel, we decided to develop a robot that can deal with such situations,” said Ken Onishi, a senior engineer in the project, citing a 2012 tunnel disaster which killed nine when rescuers couldn’t quickly reach trapped motorists because of flammable fumes from spilled gasoline.

A driver of Japanese robotics is its demographic upheaval. In 2015, Japan’s population fell for the first time, to 127 million, from 128 million in 2010. The United Nations says it could shrink to 83 million by the end of the century, when more than a third would be older than 65.

This, and a reluctance to rejuvenate the population through immigration, has cut tax income and pressured public finances.

While robotics could be the answer for Japan and other nations at an earlier stage of similar population change, the impact won’t be so benign elsewhere.

In July, the International Labor Organization warned that nearly 140 million people in Cambodia, Indonesia, the Philippines, Thailand and Vietnam, over half of salaried workers there, would likely lose their jobs to automation in the next 20 years.

0 COMMENTS