Mutsumi Industry supports customers by manufacturing products with the best quality, lowest cost, and fastest delivery.

Established in 1949, Mutsumi Industry has forged its position in R&D, design, and the production of press dies and machines for production lines. As challenges and opportunities have emerged, the company has managed to adapt.

"Japanese companies adhere to quality standards that surpass those of any other nation on the planet," believes the president, Tetsunori Kondo.

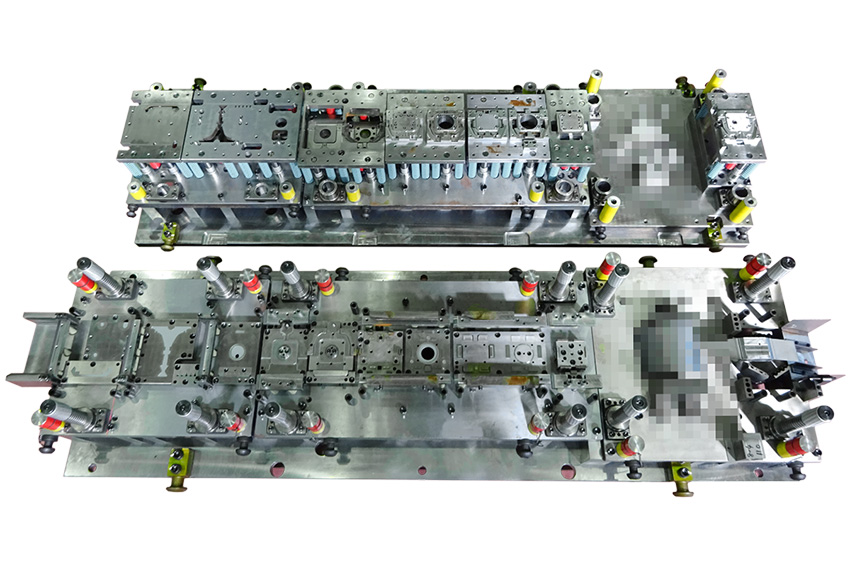

By designing and manufacturing stamping-dies and machines for mass production, Mutsumi Industry supports its customers across multiple industries including automotive, home appliance and construction. From the starting point of developing prototypes, the process is seen all the way through to production. Even after delivery to customers, Mutsumi engineers also provide support, including on-site startup, parts supply, maintenance, repair and training of workers.

"Our stamping-die manufacturing must be seamlessly complemented by top-tier engineering capabilities," Mr. Kondo says of one of the company’s key selling points. "We craft the die systematically, from analysis to 3D design, undertake virtual trials to ensure feasibility, and ensure precision manufacturing using cutting-edge technology. All our stamped parts undergo thorough inspection via a coordinated measuring machine."

The team’s expertise spans a wide spectrum, from crafting small precision components to large parts using a diverse range of materials, including high-tensile steel.

"Every machine is tailor-made with the specific details of each order arranged for every customer," adds the president. "The ability to deliver products to clients within their desired time frame holds paramount importance." Machines, AI and advancements in robotics play a pivotal role in the company’s production capabilities, including plastic forming, caulking, inspection, transfer, assembly, hydraulic, servo mechanisms, and cutting.

As the business has grown, and it explores various promotion avenues, including distribution channels, technology transfer, and partnerships, it already serves more than 17 countries around the globe. And Mr. Kondo envisions a bright future.

"The trajectory beyond this point rests upon the shoulders of the subsequent generation, with my daughter poised to steer the company's course for many years to come."

0 COMMENTS