Shinhokoku Material provides only-one invar type low thermal expansion alloys.

Shinhokoku Material, a creative leader in low-thermal-expansion alloys, focuses on semiconductor industries, with eyes on overcoming the challenges in entering established overseas supply chains. The Japanese firm’s strategy lies in collaboration with manufacturing equipment companies, offering tailored solutions for specific tasks that other companies do not attempt.

“Our mission is not just to provide standardized products,” says company president, Tadashi Naruse. “Our target at this point is to become an R&D-driven company that can contribute to the development of customers.”

The importance of overseas expansion is clear for Shinhokoku Material and the president reveals: “We plan to leverage the network we have built up so far and visit several overseas manufacturers and institutes this year.”

The company’s competitive edge lies in its ability to control the composition of its alloys within a narrower range than standard, and manage it in absolute values using chemical titration. Its low thermal expansion alloys boast unrivaled precision at 0.01ppm/K, surpassing conventional methods.

Shinhokoku Material’s relentless commitment to innovation aims to develop new alloys that can withstand use in strong magnetic fields, ultra-high vacuum environments and under high stress and hydrogen environments to become a global niche leader in this field.

Looking ahead Mr. Naruse envisions sustained growth, investing in new developments and facility expansions.

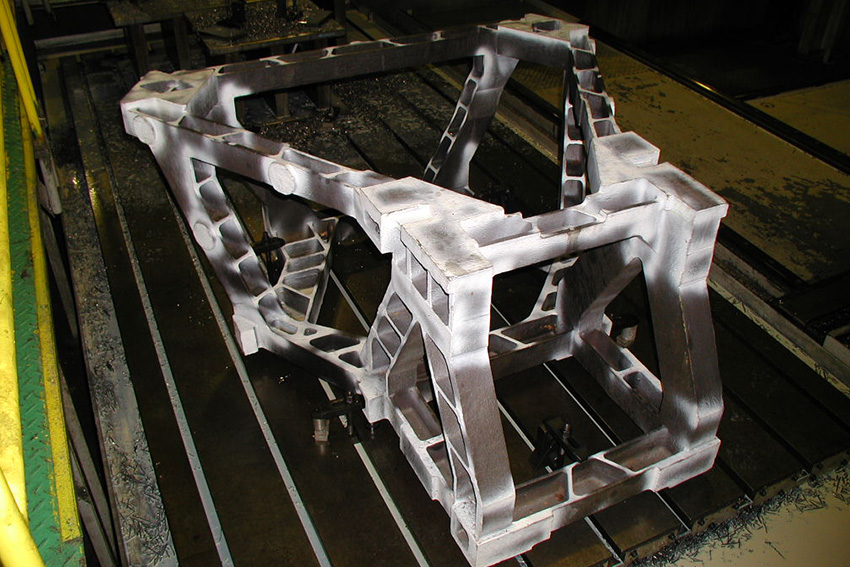

“We would like to be recognized as a distinguished manufacturer of additive manufactured alloys that can provide tailored solutions for the customers,” he expresses, highlighting 3D printing as a pivotal pillar in their strategic evolution.

0 COMMENTS