Part of the Korea Zinc Group, KEMCO has become a major player in nickel sulfate production for EV batteries. The South Korean company now plans to boost production to meet growing global demand.

KEMCO was established in 2017 in line with the increasing demand for the secondary battery utilized by the EV (electric vehicle) and ESS (energy storage system) industries and has stayed firmly put for nearly a decade. The South Korean company specializes in the production and supply of nickel sulfate—one of the core materials in the manufacturing of secondary batteries for EVs—and currently produces 80,000 tons annually, with plans to increase the volume to meet the growing demand in the EV industry.

Despite being a relatively young company, KEMCO has achieved substantial revenue growth within a short period. The company has been working hard to increase its business opportunities in the Japanese market, with 70 percent of its products being sold to Japan. Company president James Choi points out, however, that such growth has not come without its challenges.

James Choi, KEMCO

South Korea currently relies heavily on Chinese nickel sulfate and pCAM (precursor cathode active material) producers. PCAM is a core substance used to manufacture the lithium-ion batteries found in EVs. However, Mr. Choi highlights in an interview with The Worldfolio that “our main goal is to close the gap between nickel sulfate and pCam production. This is important economically but also for national security and ecosystem sustainability within the battery industry.” KEMCO has begun bridging this gap through its collaboration with LG Chem—known as Korea Precursor Company— to increase its pCAM production efforts by implementing cutting-edge technologies to create the world's largest reactor. By decreasing its reliance on Chinese production, the company plans to start channeling a substantial portion of its nickel sulfate production into its in-house pCAM production, serving as a critical link in the supply chain which could extend potentially to the U.S. market.

“Drawing from our extensive industry experience, I am confident in our ability to produce nickel products at a competitive cost advantage.”

James Choi, President, KEMCO Co., Ltd.

Along with reducing reliance on Chinese production, being able to produce nickel sulfate and pCAM in the same geographical area is important to avoid logistical constraints. This logistical constraint is one of the hurdles the company faces to break into the U.S. and European markets. However, it is a hurdle the president is confident they can address, stating: “We are committed to offering a complete package from nickel processing to pCAM production by the end of the decade. We will introduce this comprehensive solution globally in response to market demand.” Offering a competitive edge such as this over Chinese companies will put KEMCO in good stead given the ongoing worldwide realignment of supply chains which has seen Korean companies become trusted allies in both the U.S. and European markets.

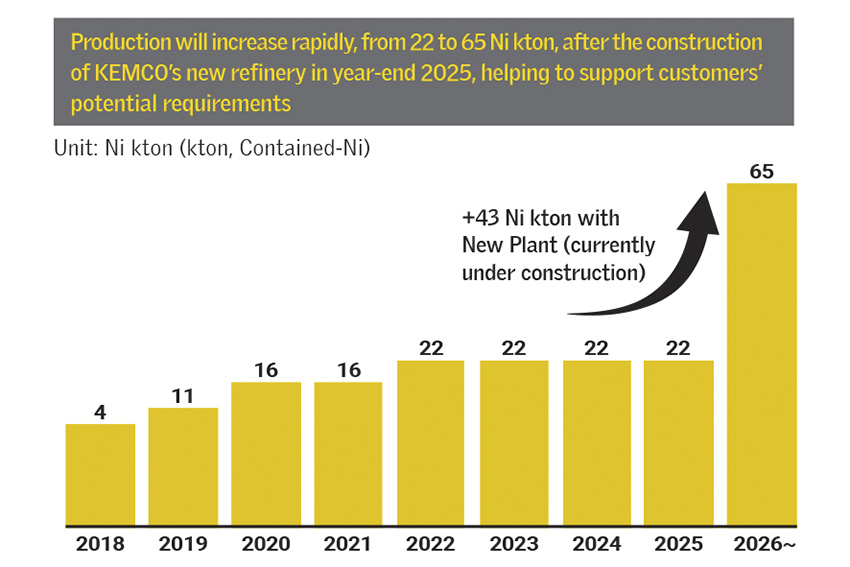

Mr. Choi explains that the price volatility of various feed materials like nickel has posed an additional hurdle for the company, necessitating flexibility to adapt to market fluctuations—something that demands substantial investment. To address this, KEMCO has embarked on the construction of an all-in-one nickel refinery, commencing this year with an anticipated completion by the end of 2025. He points out that “

by the end of this decade, we aim to provide an end-to-end solution, covering nickel processing to pCAM production. This all-inclusive approach will be rolled out worldwide to meet market needs.”

KEMCO’s nickel capacity plan

The future trajectory of KEMCO looks clear, with the implementation of its new nickel refinery, pCAM production through its joint venture, Korea Precursor Company, and defined destinations for its products. When asked about his personal ambition for KEMCO, the president highlights that whilst the company currently has a plan to build the largest nickel refinery in Korea, he hopes to provide a one-stop solution, from nickel refining to PCAM production, thereby contributing to the EV industry.

For more details, explore their website at https://www.koreaenergymaterials.com/eng/

0 COMMENTS