Since their foundation in 1995, Teras Holdings has evolved into an integrated group providing lighting solutions to a wide swath of industrial and public domains with the goal of creating a serene and easing environment.

Interview conducted with Teras Holdings president and CEO Tsukasa Fukuyama

June 2022

Can you give us an overview of your business operations? What are the strengths of your firm that make you the best possible partner in providing digital services?

We did not start out with the same kind of complex strategy as large corporations from the beginning. Various group companies were created in order to quickly formulate and provide the demands that began to be heard in the marketplace and to overcome future challenges associated with our company's management. CONTENTS CO.,LTD. was our founding business and literally started with the objective of producing digital content. In the field of digital signage, PROTERAS CO.,LTD. provides services ranging from the installation of media such as LED vision to the development of distribution software and the provision of video content on a subscription basis.

Copyright©️PROTERAS Co., Ltd. All Rights Reserved.

We were one of the first companies in Japan to realize a total solution in this field. This is one of the main reasons for our competitive advantage. In a project-based business, productivity must be constantly improved to ensure sustainability. Generally, as employee age, their physical productivity declines, and they also have greater life responsibilities, such as caring for family members and elderly parents. As a result, employees will require higher salaries and shorter working hours. We created LUCI CO.,LTD. to ensure that our employees can be consistently productive. Luci is different from the advertising production business in that it aims to produce quality finished products that can be mass-produced. Luci's domain was placed in the manufacture and sale of LED lighting equipment. Luci has a goal to provide a high quality product that can be produced by mass production. Age and physical decline are not major negative factors to continue to develop good products and increase sales. Thus, the company expanded to provide digital solutions to the Japanese society and to maintain the quality of life of its employees well into the future. Before adopting a subscription-based business model, Proteras worked on a project basis, so it was necessary for Luci to start supporting it.

What challenges and opportunities has Japan’s aging population presented your company?

Some of the products we have made are indirectly related to this situation, but we did not make these products just to overcome the problem of an aging population. We have created lighting fixtures that are used in hospitals and nursing homes to care for long-term hospitalized patients and the elderly. These facilities and their demands are growing.

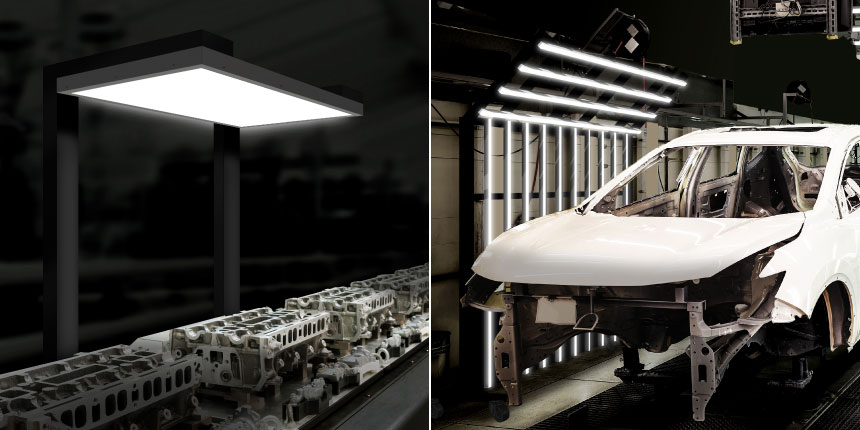

There is also inspection lighting used in automobile factories. This enhances their productivity when operators perform inspections at assembly sites. The retirement age in Japan is 65, but it may be extended to 70. Even if elderly people are physically strong, their eyesight deteriorates, making it difficult for them to see small objects such as letters accurately. Installing our lighting fixtures in automotive plants can improve the accuracy of inspections by elderly workers and reduce eye fatigue.

You mention natural soothing light for hospitals and elderly care facilities. Are these health-related products a part of a consolidated strategy or was each product a single creation as a solution for an individual client's need?

They were part of a larger strategy. For example, the lighting products we provide to hospitals have the objective of providing solid quantitative proof to clients of the value of their investment. Interior lighting, on the other hand, appeals to the subjective emotions of clients and users. It is difficult to quantify the return on the client's investment that lighting can provide by making people feel good and comfortable. This strategy was born out of the need to overcome the difficulty of continuing to grow in the mature field of LED lighting for interiors and exteriors.

The market does not demand new luminaires to be developed, even if it takes a great deal of time and investment. Companies are already able to provide excellent interior and exterior lighting to customers in this market.

About six years ago, the need to sustain our business led us to look for ways to quantify the benefits to our customers from the products and services we provide.

For example, this is the lighting we installed in one of our client’s facilities.

ATLAS Bar, Parkview Square / Photo: E.K.YAP

It illustrates the usefulness of internal and external lighting in a commercial facility to increase revenue. The use of this type of lighting should demonstrate that it will directly increase sales. However, it is quite impossible to quantify exactly how much profit is generated by the installation of lighting.

You mentioned the lighting field being mature and there is no need for innovation of new products. What is your current challenge for product development if not innovation?

First of all, there is no need for new product innovation in the field of lighting. This is a bit of an oversimplification. I will say exactly what I think. I believe that the LED lighting products for interior and exterior applications that are available around the world today are able to fulfill most of the market needs in this area. The majority of the application development has been accomplished.

In the early days of this field, there were many revolutions in the interior and exterior lighting market that were driven by the use of LED as a light source. Today, this field is certainly more mature than it was then.

Still, I believe that many companies, including ours, will continue to make improvements and small developments. Of course, there may yet be major innovations, and price rationality will always be pursued.

And under such circumstances, companies that can pursue cost rationality by leveraging their larger capital and sales scale will have an advantage.

As a small and venture company, we decided to focus our innovation on lighting products that allow us to visualize and prove the return on investment of the customers who purchase our products. If we want to have a business plan that will continue to grow over the medium to long term, we must show how our products are directly related to the growth, sales, and profits of our customers' companies.

It is difficult for me to be certain and plan for continued growth when we work only in the very subjective area of interior and exterior application lighting.

Nevertheless, there are many other areas where LED lighting can create new innovations besides interior and exterior applications, and there seems to be a solid market for it. Have you ever heard of the term circadian rhythm? It refers to the mechanism by which our internal body clock works according to the type of light we are exposed to. So one way to get rid of jet lag is to get direct morning sunlight when you arrive at your destination. That sunlight resets the body's internal clock and allows it to adjust its biological functions to the actual time in that location. Sunlight changes its spectrum throughout the day, from morning to midday to evening, and our genes thereby advance our internal body clocks. For patients who are indoors and do not receive much sunlight, such as those in hospitals and nursing homes, it is difficult for their body clocks to catch up with their circadian rhythms. As a result, they have difficulty sleeping at night. These patients often become anxious and unstable, especially at night. Nighttime is the busiest and most stressful time for workers in nursing homes and hospitals. Patients must find ways to cope with their anxiety and are more likely to press the nurse call button for help. Tranquilizers are sometimes injected to help patients cope with their stress. In today's world of heightened human rights awareness, administering tranquilizers is not the best solution. Instead of relying on sleeping pills and tranquilizers, it would be preferable to improve sleep by introducing lighting that supports the patient's internal clock. Lighting that can create similar wavelengths as the spectrum of sunlight changes with time can create a natural way to improve their sleep. This solution will also allow staff to better manage patients and reduce some of their nighttime work hours.

Medical Corporation Showa-kai Hokkaido Gastroenterology Hospital

If we can achieve a reduction in working hours and workload, this will prove to be a benefit gained by our clients. This is just one example of how our functional lighting products can contribute and prove to the user's operating revenue.

Are these types of health facility focused products mostly intended for Japan or are they a solution that you intend to export to overseas markets?

We are also looking into exporting our products to other countries. Lighting fixtures that assist the body's natural circadian rhythm are beneficial to all patients, regardless of region or race. The better sleep patients get, the faster their recovery will be and the shorter their hospital stay will be

With the foreign market in mind, you have mentioned the importance of collaboration with foreign firms both in terms of technical development and finding contract manufacturers. What type of overseas partners are you looking for and in which market are you looking to find new partners?

We are looking for a sales partner to distribute our products to automotive plants around the world.

The automotive industry is in a sense a closed market. It is not easy for new suppliers to deliver equipment. They are very careful with information. It is very difficult for outsiders to know what products they make and how they make them. We are looking for sales partners who already have the trust of the automotive companies, who have the status to deliver production equipment and facilities to automotive plants. We have already managed to get direct orders in Argentina and Thailand.

Even though you do not do any of the manufacturing yourselves, you have a presence in these factories by assigning quality control engineers on-site. Can you tell us more about the advantages or disadvantages of being a fabless lighting manufacturer? Are you looking for new contract manufacturers?

The greatest strength of this business model is the ability to develop a high-mix, low-volume business. Another advantage of this business model is the ability to select factories according to the various advanced technologies and conditions required to produce a particular product. For example, let's say you have two types of lamps on this ceiling. If one has five different lens units, then the key device of this luminaire is the lens. If we were to manufacture this luminaire, we would choose a company that has high production technology and production facilities regarding lenses to make the best product. If the product is to be used underwater, we would choose a factory with strong waterproofing and leak-proof technology.

There are two general types of manufacturing. One type is where all components are manufactured and assembled in-house. The other is to procure parts from various manufacturers and assemble them in-house. We chose the latter in order to optimize the cost and functionality of our products. Luci was established at a time when it was not yet clear what form and function the market needed. So we made this choice to allow for flexible product development.

In Japan, the traditional vertically integrated production system is preferred. This model requires complete control over everything in manufacturing a product. A major Japanese electronics manufacturers also adopted the vertically integrated production model for the production of LED lighting, but later stopped because this model was no longer effective.

I have only ever done fabless production, but there must be some disadvantages. If you are fabless and procure parts from a company that also supplies parts to other companies, your know-how and designs may be shared with competitors. Also, for suppliers, keeping equipment running 24 hours a day to produce the same product is most profitable, so they will prioritize large-lot customers over small-lot customers. Fixing assembly lines is important for contract factories. Different manufacturing lines are needed to serve specific customers and products. Therefore, it is most desirable for manufacturers not to reset or relocate manufacturing lines too often. Each reset increases idle time and affects productivity.

Therefore, we must constantly strive to build a relationship of trust with our contract factories in order to achieve the optimum lot size, delivery time, and cost for us.

We are always looking for factories that have the capabilities we need for our newly developed products. The most important factor in this decision is not only the technology and functions they possess, but also the human qualities of the top management. No matter how careful we are with our projects, unforeseen things can happen. At that time, the most reliable way to quickly take the best possible measures is to make sure that management has the right stance.

Are any of your contract manufacturers in Japan?

Approximately 20% are in Japan

The last few years must have been a nightmare managing all the delays in terms of logistics. How have you been managing logistics disruption?

The most severe impact of the pandemic was the reduction in the number of shipping containers and the shutdown of port loading and unloading due to the Chinese city lockdown. And then there was the shortage of semiconductors.

Shipping rates increased dramatically, and delivery times sometimes took two weeks or more than before. Fortunately, we are a high-mix, low-volume producer, so we were able to cope by switching to air transportation in an emergency.

However, the shortage of semiconductors continues to be a major issue. The key device in our products is the LED element, which is made from semiconductors. Semiconductors are also used in other components.

We have a close relationship with our suppliers, and we receive priority shipments of semiconductor components, so there are currently no delivery delays due to semiconductor shortages, but we have to order six months to a year in advance, which has some impact on our cash position.

We are also concerned about geopolitical risks, although they are not currently apparent. Of all the countries in the world, the production of LED elements is concentrated in the Shenzhen area of China. Many of the major manufacturers of high-performance semiconductors are located in Taiwan, on the opposite coast from Shenzhen. Taiwan is said to account for more than 60% of the world's semiconductor contract manufacturing share. The political situation between China and Taiwan is very unstable. And once conflict erupts in the region, the supply chain for electrical equipment worldwide will be equally paralyzed. Many businesses, both semiconductor and LED device manufacturing, may find it difficult to continue unless they stop being so heavily weighted toward Taiwan and southern China and have diverse fabs in other parts of the world.

I think it is a great opportunity for the Japanese government to invest in building a high-performance semiconductor contract manufacturing fab like WSMC in Taiwan here in Japan to take advantage of its robust manufacturing technology. The US is beginning to make such investments. I have heard that the US has decided to invest a huge amount in domestic 5G nano semiconductor manufacturing. Japan is a little behind in this matter.

If we come back on the last day of your presidency, what goals and dreams would you like to have achieved by then?

My primary concern is to mitigate the company's future risk while allowing it to grow. By doing so, I hope to make the company an entity that can survive for the very long term.

In the digital signage business, the real growth in this area is yet to come. As the market grows, it will be important for us to look at the market in a segmented manner and determine which of these markets we will aim to capture the lion's share of. This also leads to the fact that only companies with the top market share will be able to survive in the subscription-type business.

In the Luci business, we have begun to diversify our business domain from interior lighting to lighting for automobile manufacturers. This is to make the cycle of the company's lifeblood that even if one business domain peaks out, the next main domain soon compensates for it. So our current goal is to quickly increase our internal market share in the automotive field.

I also want to make sure that our employees feel more that their work is rewarding throughout their lives as well as the certainty of our business. The primary reason many people work is for material income, but that alone does not satisfy workers. I want to be able to provide an emotional income to my employees. Job satisfaction varies from individual to individual. However, there are also universal factors involved. For example, if one's work leads to saving the lives of others, one will certainly feel a sense of job satisfaction.

I myself experienced dengue fever in Singapore. It seems that I was bitten by a mosquito that carries this disease while swimming in a pool at night. If, for example, the insect traps that have already been developed by Luci can be used to capture disease-carrying mosquitoes and serve as poolside lighting in the future, perhaps we can reduce the incidence of life-threatening diseases. This is a feasible solution.

I want to make our company something that not only provides tangible benefits to its customers, but also makes the people who work here happy for the rest of their lives.

0 COMMENTS