With its latest 3D-AOI and X-ray technologies, Saki Corporation is the global leader in automated inspection equipment for PCB and semiconductor manufacturing.

The world-renowned superiority of Japanese manufacturing is underpinned by the concept of monozukuri. Made famous by the likes of Sony and Toyota, monozukuri encompasses craftsmanship, an ardent focus on high-quality production and the constant pursuit of innovation. While household names like Sony, Toyota, Nissan and Honda may be the visible face of Japanese manufacturing on the global stage, the true strength of Japanese monozukuri lies with the nation’s smaller and lesser known manufacturers – many of which, like Saki Corporation, work behind the scenes, supplying parts and equipment to these larger firms.

In 1994, Saki Corporation started supplying inspection devices to Sony. Today, the company is a global innovation leader in automated inspection equipment for printed circuit board (PCB) and semiconductor manufacturing.

As the PCB and semiconductor industries have developed and become more ubiquitous with the advent of smart phones, smart devices, advanced robotics and the latest computerized automobiles and home appliances; Saki Corporation has adapted to constantly changing demands to build the most sophisticated state-of-the-art inspection systems, trusted by clients in Japan and across the world.

“Thanks to monozukuri, technology has evolved, and the components used in products have become more precise and intricate with a much higher level of detail and complexity. Our inspection systems have therefore also evolved to suit contemporary trends, fi rst from 2D to 3D and then on to X-ray,” explains Saki president and CEO, Norihiro Koike.

Initially Saki focused on 2D devices, with its global expansion driven by the adoption of the monozukuri philosophy overseas. With the rise of cheaper competitors on the global market, Saki Corporation moved to distinguish itself with 3D and X-ray technologies for clients manufacturing high value-added products.

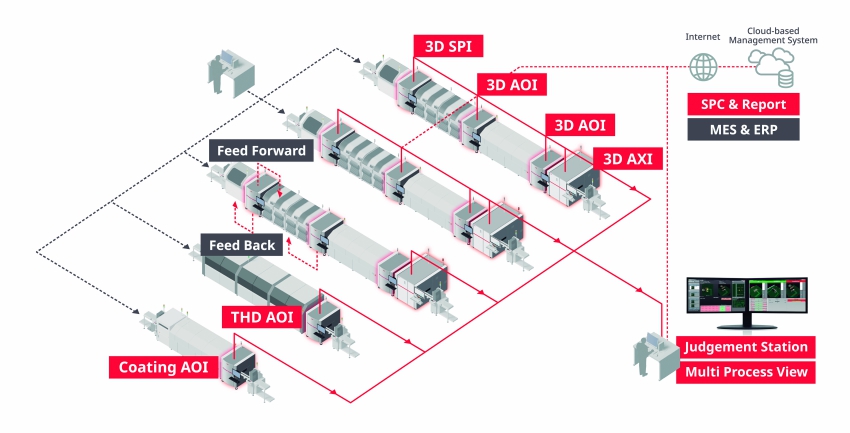

In today’s highly sophisticated manufacturing landscape, characterized by automation, IoT and Big Data, Saki’s systems compare, evaluate, collect and deliver critical feedback to the manufacturing process, and thus ensure the highest levels of control through the provision of high-accuracy inspection and measurement.

“Delivering this detailed and accurate data is the primary driver behind our decision to create both 3D and X-ray technologies,” adds Mr. Koike.

Today, Saki’s best-selling equipment is its 3D-AOI (Automated Optical Inspection) system that meets the stringent standards demanded by surface mount devices. Saki’s technology enables precise inspection of PCBs and the detection of the most difficult defects.

As a leader in 3D-AOI development, Saki has introduced its 3rd generation AOI systems: flexible, adaptable, high-quality and costeffective systems that can be used across a range of inspection applications, from simple verifications to full algorithm-based measurements.

Driven by increasingly sophisticated technical advancements in markets including autonomous vehicles, aerospace, medical and 5G applications, Saki is also introducing its 2nd generation AXI (Automated X-ray Inspection) systems that ensure the highest quality and reliability of end products through the provision of integrous measurement and feedback data. Saki’s AI-based technology is essential to achieve true automation in the electronics manufacturing industry of the future.

In an ever-changing world, monozukuri efficiency is central to Saki’s corporate DNA as the company continues to focus on cutting edge R&D, expanding its technologies to provide added value and meet the expectations of its global client base.

0 COMMENTS