Toyo Kensetsu Kohki innovates with high-quality rebar processing and automation, emphasizing human resource education and global service excellence.

Japan’s rebar industry has grown, closely aligning itself with Southeast Asia, and a big factor we saw during our research is Japan’s susceptibility to earthquakes. It poses a big challenge to construction companies in terms of how they conduct projects and how they manufacture machinery. Obviously, this requires much more stringent standards, which many believe gives Japan a competitive edge when it comes to construction-based technologies and projects, especially when compared to China and other countries that do not have such natural disasters. Can you explain to us the point of view of Japan’s susceptibility to natural disasters and how it helps create something more competitive internationally when it comes to construction-based projects?

It is rather difficult to answer that question because we cannot speak on behalf of all Japanese construction companies, but more generally, innovation in seismic technology is certainly an advantage when it comes to Japanese companies. After each major natural disaster, construction standards have become stricter, and innovation in seismic resistant construction techniques and materials have made Japanese construction companies more appealing in foreign countries.

In Japan there are frequent occasions for these natural disasters such as earthquakes and tsunamis, so in essence, Japanese companies are much more aware of the dangers these pose, and thus, are more experienced in disaster response and recovery techniques. Again this contributes to the global reputation of quality and reliability, hallmarks of Japanese construction. We do contribute to the development of safer and more resilient infrastructure in Japan and around the globe.

Of course, every coin has two sides, and we can’t just paint an overall positive picture without talking about some of the negative aspects. When talking about the country’s stringent construction standards, we are often talking about standards that far surpass those required in other countries, particularly in Southeast Asia. In other words, each country has its own legislative processes, making it sometimes difficult to promote and implement the standards and technologies developed here in Japan. In some other cases, there are countries that experience few natural disasters. In those cases, they literally don’t need technology coming from Japan. Additionally, the high price of Japanese construction companies can sometimes be a sore spot and can be seen as not an advantage in comparison to local players. A key point we need to follow is to analyze the market outcomes and where infrastructure development is taking place abroad. It essentially comes down to a balance between quality and quantity, tailoring solutions to the specific company or country.

Japanese construction companies are often described as over-spec and as possessing too much technology. In many cases, these technologies are optional in overseas locations, which can be a double-edged sword.

Right now, with the increasing frequency of large-scale natural disasters worldwide, Japanese technologies and techniques in disaster prevention are becoming increasingly necessary. In those locations, we do possess an advantage, giving us space to implement projects in construction in niche areas. One thing we want to stress is our never-give-up attitude, and we truly believe that at some point in time, in any country or region, quality will prevail over price. We are patiently waiting for that appropriate time. Soon, the focus will shift from a low-cost, quantity-over-quality approach that relies on cheap labor to one that places greater emphasis on sustainability, reliability and safety. We will be able to provide optimal solutions at a decent price at that time. At the end of the day, high-quality standards matter and are advantageous in the long run.

Patience is the key right now. We aren’t looking to rush the process, and when the time comes, we will be ready and willing to provide our services overseas. We are not just waiting idly, however. We are actively analyzing the markets, performing due diligence to speed up the process, and making efforts to convince vendors outside of Japan about the core advantages of Japanese construction firms.

Toyo Kensetsu Kohki is a domestic leader in rebar processing machines, holding an 80% market share. In recent times, you have expanded your focus to include services such as repair, maintenance, and component supply, ensuring comprehensive support for your clients. What have been some of the biggest challenges in developing these additional services for overseas markets?

As you mentioned, we possess an overwhelming market share in rebar processing machines, 80% in the domestic market, to be precise. Obviously, this didn’t happen overnight, and we’ve been walking a very long path to obtain this market share, a path that has taken 65 years to reach this point. Such services are not something we have started to focus on recently; they have been at the core of our value from the beginning. Our swift and appropriate responses have earned the trust of our customers, leading to our current position as the domestic market leader. Investment in equipment and updating our expertise are crucial to obtaining the highest level of quality.

Regarding the challenges, time is certainly one. Achieving what we have isn’t something that can be done quickly. It was only possible thanks to the technical expertise and skills that every single technician has poured into our company and that has been handed down to new employees through training. We consider our salespeople to be more than just salespeople, and as a company, we are very proud of our human resources. While we have technical specialists, our salespeople are different from ordinary salespeople since although they perform sales activities, they are also capable of performing technical duties such as machinery installations, basic repair and maintenance after-sales services. This is why it takes five years of training for personnel to achieve this level. In a sense, even training is a long process that requires dedication, although it is essential to produce human resources that can uphold the top quality we provide.

This is where we reach the challenge aspect, since fostering human capital is something that has proven difficult to many Japanese companies. Growing and teaching new personnel about our company, nurturing them to a point where they can conduct activities as a one-man-show is certainly a key challenge that we must face head-on.

These hardships also apply overseas as well, especially when we talk about investing in continuous training programs. Our story isn’t just a domestic one, and we must apply a similar approach in overseas markets. If we cannot do this by ourselves for some reason, then we will try to find a proper distribution company that can perform duties at the same level as we do here in Japan.

Toyo Kensetsu Kohki has established a robust overseas network with local partners across various Asian countries. Each partner is strategically located in key cities and regions, including Bangkok, Phnom Penh, Jakarta, Manila, Cebu, Davao, Taoyuan, Jincheon-Gun, Ho Chi Minh City, and New Delhi. This network ensures localized support and distribution. Where have you been focusing the most resources on since we interviewed you in June last year? Where do you see the most growth potential moving forward?

Firstly, we do appreciate you following up with our company after visiting us last year. Over the past 12 months, little has changed; however, one particular focus has been increasing our presence in Southeast Asia. Now, we are aiming for areas with huge populations such as Indonesia. We have expanded our business to that country and furthermore, we strengthened our partnership with a local distributor to cooperate with us in tackling this market. As a tangible result, for the first time in the history of our business expansion into Indonesia, we were able to deliver some automatic machines to a local steel manufacturer this year.

Unfortunately the story with Vietnam was not that good, but this isn’t just something that is affecting our company, rather, the entire economy for infrastructure in Vietnam has reached a stage of stagnation. This has meant that we are not able to acquire as many projects there as we would like. Currently we are on hold in Vietnam, waiting patiently to see how the market will play out.

One issue hampering Japan’s construction sector's growth is its aging population. Almost a third of Japan's population is over 65, and one in ten people is over 80. This creates bottlenecks in labor and supply chain logistics and, for construction projects, a manpower shortage on site. Companies, governments, and industry organizations all have a role to play in addressing these challenges. What actions do you think have been most effective in addressing Japan’s construction labor challenge?

In the rebar industry, which is also true for the entire construction industry, there are stages of automation which are being addressed alongside challenges such an aging workforce and labor shortage. In the past, when labor costs were low and manpower was scarce, rebar was processed at each job site using manual machines. As labor costs increased, however, rebar processing was consolidated in factories, and greater efficiency was demanded. In response to market needs, we have developed automatic machines. In order to further reduce the physical burden on workers, we have incorporated automation technology into our machine systems and are researching the use of new technologies such as robots.

Now that we have made some progress in automating rebar processing in this way, the on-site installation of rebar has become more of a bottleneck. While cutting and bending of rebar accounts for about 20% of all rebar work, 80% is the assembly or installation of rebar onsite. In order to reduce the amount of on-site work, research has been conducted on methods to pre-assemble the rebar in a factory, transport and then install it onsite. In addition, automation such as automatic tying of rebar and assembling robots are being developed, but the use of such technology is currently limited because each construction site situation is so different.

Under these circumstances, precast concrete is attracting more and more attention these days. By performing the rebar fabrication and installation, formwork, and concrete casting in a factory, and then assembling the finished components onsite, work is simplified in many ways onsite, making up for labor shortage and increasing work efficiency. While we will discuss in more detail later, we are working with our partner to solve problems in the construction industry through the automation of concrete product manufacturing equipment. We are already in positive discussions with several general contractors.

It is unfortunate that these precast concrete technologies are currently only applicable to some construction sites, but it should be widely used in the future. As I mentioned earlier, all construction sites are different and unique. With that in mind, it is very important for general contractors that are at the top of projects to use precast concrete and other automation technologies. In response to this trend, we believe it is our role to propose solutions that automate not only rebar work but also the production of high-quality precast concrete products.

Your TFC-LAV is an automatic rebar-cutting machine designed to cut and store large quantities of rebars efficiently. It features a user-friendly touch screen for precise length settings and supports combination cutting of different lengths. It can also be paired with automatic sorting and feeding devices for enhanced efficiency. Can you explain the technology integrated into the TFC-LAV that helps reduce the need for extra manpower?

The TFC-LAV you mentioned cannot maximize manpower saving and work efficiency by itself. We developed the basic specifications for faster and more convenient cutting processing, assuming some degree of human intervention. In order to reach 80% of the domestic market share, we would need to apply all possible methods to meet all possible needs. The TFC-LAV is just one solution and part of a bigger picture. The solution that satisfies our customers varies depending on the type of business, scale, and budget of the customer. For example, for customers who require full automation, we can propose the TAS-II, a device that automatically feeds and aligns rebars from a bundle to a conveyor while counting the number of rebars one by one. On the other hand, for customers who do not require that level of automation or who wish to reduce initial investment, we can propose simple additional equipment or other cutting machine models. We have a wide range of cutting and bending machines, all of which are also aimed toward customer satisfaction. This also allows us to make proposals that meet the various standards of Asian countries. For the long history of our existence, we have accumulated a client database that shows customer preferences. Although we now have a huge market share, it has been a bumpy road to achieve that. All machinery we produce is ultimately aimed at making sure customers are 100% satisfied.

For most construction projects, rebar is used to reinforce concrete and masonry. The primary material used is carbon steel, a material with a high tensile strength, making it an ideal material. In environments requiring corrosion resistance, stainless steel rebars, epoxy-coated rebars, and galvanized rebars are utilized to ensure durability and longevity. Are there significant differences between rebar machines that process different types of materials, and what are some of the challenges you face?

Yes, many construction companies are employing different kinds of materials, such as epoxy-coated rebar and galvanized rebars. We fit the expectations of various construction sites due to our high-spec machinery. Stainless steel, for example, while is used in hospital MRI rooms where non-magnetic properties are required for building, requires more force when cutting than cutting ordinary rebar. Our machines can meet those needs. We are capable of handling various types of rebar processing.

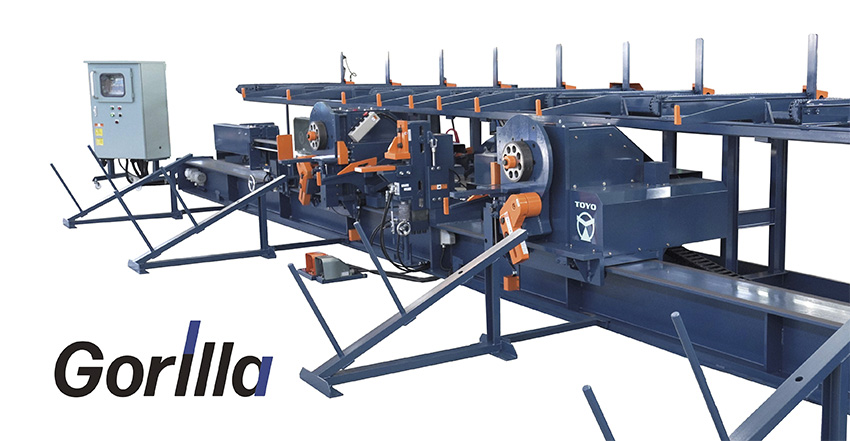

In March this year, you announced the introduction of the “Gorilla,” a nickname for your new automatic bending machine for the main bar, Model BSI-41Y4-V. Designed to be compatible with SD490 reinforced steel, the Gorilla inherits and enhances the powerful aspects of its predecessor, the TBM-41-1ASV. Why is it called the Gorilla, and what were the reasons for deciding to update the TBM-41-1ASV this year?

The name comes from the inspiring strength you see in gorillas in the wild. We decided that since this machine could bend the thickest rebar diameter among our automatic machines, we would nickname it after one of the strongest animals. We actually wanted to nickname it “Godzilla,” but because of copyright issues, we ended up with Gorilla.

While there aren’t too many drastic changes in appearance in comparison to the previous model which has been patronized for many years, what's inside has been significantly upgraded. Whereas before you had to manually turn a dial to set the angle, now you can input the values directly via a touchscreen, greatly improving the usability for everyone. Furthermore, the newly incorporated TLINKS system will make it even more powerful. For example, a major evolution would be the ability to remotely transfer processing recipes such as rebar dimensions, angles and number of rebars to bend to the machine. This TLINKS will be upgraded with all the functions related to rebar processing and production management through future expansion of the service. We are confident that both Gorilla and TLINKS will be an important position to answer the industry's current manpower shortage that we are currently facing.

Since 2017, Toyo Kensetsu Kohki has been working with PROGRESS GROUP, a company headquartered in Italy, to offer automated equipment and software for manufacturing concrete products. What type of new partnerships have you identified the need for as part of your long-term strategy for growth?

Currently, we are working on several projects in collaboration with the PROGRESS GROUP. Unfortunately, I cannot reveal too much information at this time because of NDAs, but we expect to make an announcement soon. The PROGRESS GROUP isn’t the only company that we are working with right now. We also work with various companies beyond those involved in precast concrete manufacturing equipment. If needed to solve our clients' challenges, we are committed to further expanding and strengthening these partnerships.

For more information, visit: www.toyokensetsukohki.co.jp

0 COMMENTS