In the ever-evolving landscape of Japanese manufacturing, Nakao Seisakusho stands as a pivotal player. President Hiroyuki Nakao discusses its strategic response to global economic shifts and demographic challenges, positioning the company for international expansion.

It is our view that Japan is at a very exciting time for manufacturing. On one hand, we have had major supply chain disruptions in the last three years, caused by the COVID-19 pandemic as well as tension from the China-US decoupling situation. As a result, we are seeing many multinational groups try to diversify their supply chains with a focus on reliability. This is where Japan can enter; a country known for decades of high reliability, trustworthiness, and short lead times when it comes to production. Now, with a depreciated JPY, it is our view that there’s never been a more opportune moment for Japanese manufacturers to meet the pressing needs of this macroeconomic environment. Do you agree with this premise, and why or why not? What do you think are the advantages of Japanese firms in this current economic environment?

Obviously, we cannot draw a picture for you of the whole industry, rather we can only really relate your question to our situation and our construction business within home design. Conventionally, the industries that were thought to be the most vulnerable during the COVID-19 period were the tourism sector, and they were the most impacted by the pandemic. I think that in terms of our industry, we were blessed because before, during, and after the pandemic we have maintained a stable supply. We are okay with the domestic market situation, however, we can’t necessarily say the same about foreign markets. During the pandemic and even to this day local production factories of ours in China are shut down, and therefore there isn’t a stable supply there. This is a big negative and a real impact of the COVID-19 pandemic.

In order to withstand the situation in China we have been conducting activities inside the company. One part of those activities involves stocking products at least 6 months before expected orders come in from the customers. This is the only way we could survive the rampant supply chain disruptions that we experienced during that period.

Another aspect we wanted to talk about was Japan’s demographic situation. Japan has an aging and shrinking population. It is estimated that by 2050 the population will drop under 100 million with one in three people over the age of 65, meaning that Japan is facing a labor crisis and an issue of technical inheritance, but then there is also a shrinking domestic market to sell products to. What are some of the challenges this demographic shift has presented to your firm and how have you been reacting to them? To what extent must firms like yours look overseas to ensure long-term business success?

There are a few aspects to look at with the problem you mentioned, and one in particular is that this situation has country-wide implications, not only for the construction industry. At the same time, there are business opportunities that can come from the demographic shift. We have things like nursing homes being built in Japan to accommodate the aging demographic. With that in mind, I think that companies like ours are going to be okay for the next 5-10 years at least.

Different initiatives need to be taken by companies, including ourselves. Those include things such as R&D enhancements and value-added products. This is the path to overcoming our rivals since our market itself is very cost-competitive, especially for the installation of doors.

From a foreign market perspective, there are several opinions. In my opinion, that is not looking too optimistic, especially with our experiences in China. We still have manufacturing in Shanghai and Shandong, but we feel there is now a significant country risk associated with Chinese production. We’ve analyzed everything and come to the conclusion that conducting business in China means being tied up with local governments, and therefore very hard to sustain a good, healthy business environment. Unfortunately at this time, this is just the specifics of the country.

We’ve actually been conducting business in China for a long time now, and precisely 32 years ago we began conducting local production in the area. Throughout that time we’ve seen a lot of neighboring Japanese companies come here too, and some have gone bankrupt in the process. I think this speaks to the idea that China isn’t the ultimate solution. We’ve thought long and hard about the solution, and we believe that the way out of China would be to nearby countries like Vietnam, Indonesia, or Malaysia, and we plan on pulling the trigger within the next 12 months. In fact, we are deep in discussions about Vietnam being our next destination.

We are a company that moves society

In many interviews with key players in the industry, they mentioned that in order to unlock the international market there is a need to partner with local companies in order to better understand the needs of a locality. We know that your firm sells your products in China and Thailand on top of Japan, so with that in mind can you tell us the role that partnerships play in your business model? Are you currently looking for any new partnerships or collaborations in overseas markets?

I would like to see my company in good relations with some local partners because we don’t know the markets whereas local players do. Obviously, we would need to conduct due diligence and analyze markets before going to any location as well as trust the opinions of experts who understand the market.

Another step we should take is increasing brand awareness. Getting our name out into markets and introducing our products will lead to increasing our work with local partners.

In my opinion, it is very important to segregate products that are made in China and products made in Japan. Only an expert in the field can do so properly and then find end users in local markets.

Southeast Asia has a lot of potential since when you have one location you also have access to a lot of neighboring countries. It is very easy to commute, so moving from Malaysia to Singapore for example is a very smooth process. It allows our firm to not limit itself, and Vietnam would be a great location since there are already a lot of Japanese companies there conducting business. We are trying to penetrate other Southeast Asian markets, but I think that is only possible with the help of a reliable local partner.

What kind of strategies are you looking to employ in order to successfully transfer your overseas operations to Southeast Asia? Are you interested in any M&As or joint ventures?

Opening up more distribution channels will be the focus, however, it is very hard to say exactly because the countries are very close to each other, yet each has its own language and culture. We had our hands burnt by our experiences in China, so we are a little hesitant because we don’t want to have the same experiences again. Therefore we need to be cautious and take keen steps when approaching new countries. Joint ventures aren’t something we are looking at right now, I would rather focus solely on opening further distribution channels with local players.

There are two patterns I see here, with one being a similar approach to that we took in capturing the domestic market. Domestically, however, we do still have a way to go. In order to acquire a greater market share domestically we not only have to be providing top-notch products but also we need to renew the equipment that we have on our premises. We do have two factories in Japan, with one of them in particular having outdated equipment. We have to renew and modernize in order to level up the product quality we offer clients.

Foreign markets don’t necessarily follow the same patterns as the Japanese market. We did see an opportunity in the past to open a joint venture which we took to the initial stage, but honestly, it required too much from us in terms of finances and time. It meant that we had to apply so much of our mental capacity to adapting to a new culture and mindset. It also required so much extensive investment for us to purchase equipment and hire experts. That initial stage was a hardship that inevitably was difficult to endure. We have struggled and ultimately, to that end, the solution in my mind comes through increasing the quality of products produced here in Japan.

Shuttle Closer

Over the last 25-30 years Japan has seen a rise in regional manufacturing competitors from countries like China, Taiwan, and Korea, who have replicated Japanese manufacturing processes but done so at a cheaper labor cost, however, despite this Japanese companies have remained leaders in certain niche, B2B markets and have high global market shares. With this in mind, what do you believe to be the main advantages of Japanese firms that have allowed them to remain leaders in these specific fields? What is the appeal of Japanese firms to prospective foreign clients?

First of all, since we are a door manufacturer we need to think about the kinds of doors that are common in certain markets. It might sound like something obvious, but equally, it is important and something that is easy to overlook. Surprisingly the standards of door manufacturing differ from country to country. Another difference is quality expectancy, and to some extent, we have experience in this regard with our venture in China. In particular, when we were in China we introduced 3D CAD design in order to accommodate the hinges, which might not have been the best strategy for China since the quality expectations in that market are quite low. Many sales activities saw comments suggesting we were producing over-specifications, so in hindsight, we now understand that conventional hinges work for this market.

Having said this, times flow, and things change. The Chinese market is one that has evolved rapidly and the quality expectations there are constantly on the rise. High-quality products are now being highly appraised and for a time doors were flying off of the production lines into customers' hands. I think at the end of the day, the point I’m trying to make is that it is absolutely vital to understand customer wants and needs. Feeding the customer's expectations is the simplest path to success. That is why we are doing the activities we are doing in Southeast Asia, setting up our clear path to success.

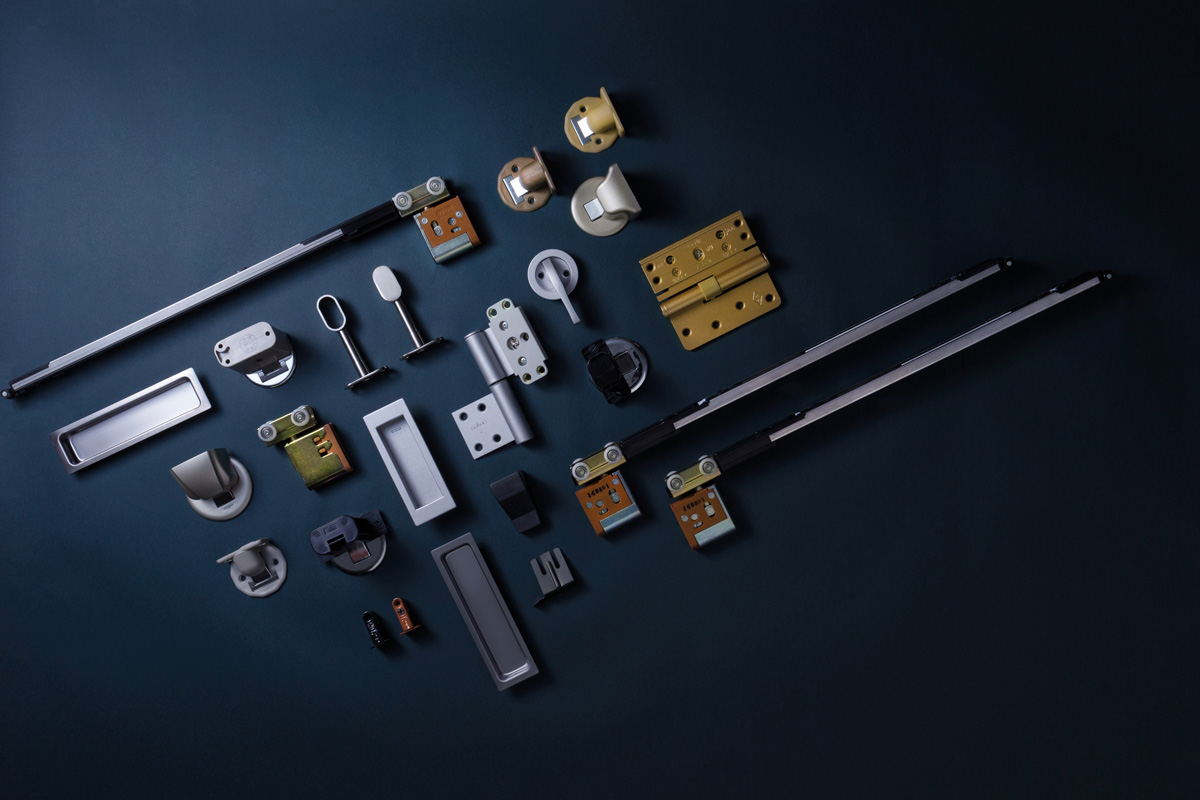

Your firm started by producing hinges for Buddhist altars and furniture and now you specialize in the manufacture of various products to install sliding, folding, and opening doors. Among all of the various products you provide, which do you believe has the most growth potential?

The strategy right now is to emphasize our strongest product which currently is in sliding doors and door stoppers. We sell these more than any other product so we would like to have an extensive lineup of products for these two segments.

What separates our products from our competitors lies in the enhancements that we make through our R&D activities. We constantly look for new features, new solutions, and new materials to increase durability and functions.

The door fitting market is famous for being very cost-competitive. Your company is cost-competitive with your production in China, but you’ve also added value to your products through various features. Could you tell us more about your added value developments? What are some specific examples of functionalities you’ve been able to add?

Unfortunately, I cannot speak extensively on this since some of the information is confidential trade secrets. The one thing I can say for sure is that we do things that no other company can do and I can say that it is related to door pockets.

You are right that the market is cost-competitive, and while some are more expensive, and some are cheaper, in general, the quality is still high throughout. Door pockets are our solution to this competition. If you’ve seen usual door pockets you might know that they aren’t normally aesthetically pleasing, but our plan is to change that while also creating a product that allows sliding doors to go in and out with ease.

Magnet Stopper

One of your standout products is your Shuttle Closer, a closing device that reduces the noise emitted by opening or closing a door. Since the device is one piece of hardware you are able to be more cost effective and save on construction time as well. How is the Shuttle Closer superior to similar closing door products available in the market?

Although the differences between various products might be small they do add value and that is crucial in such a competitive market. As for the Shuttle Closer, its key feature is the smooth operation, which I think defines everything about the closer. With this feature users can open and close doors in a smooth way no matter the width or weight of the door. As you mentioned, this can reduce costs through the reduction of construction time, and to that end, it provides users a seamless experience. The product is also designed to be extremely durable, meaning it will last a long time and therefore save the user more costs because they don’t need to replace it often. Noise reduction comes from the smooth operation feature, and I think this is one of the features that users appreciate the most. There are environments where noise reduction of doors is essential such as hospitals, schools, or laboratories. Customization is one more feature that the Shuttle Closer can boast, and the product can be customized to fit different doors with varying sizes, shapes, and weights.

R&D for the Shuttle Closer took between 6 months to a full year. The personnel were able to work very quickly with customers in order to come up with an excellent product that customers really appreciate. I think any side of this equation that also appreciates this product is the maintenance workers. Since it is one piece of hardware rather than two we save those workers construction and installation time, thus simplifying their work and solving problems from multiple perspectives.

Sliding doors are very convenient where there is limited space, but at the same time, they come with some issues. Most sliding doors are suspended from above, and when the door is closed there is a floating space below the door, reducing the air tightness of the room, and allowing air, light, sounds, and heat to enter. How does your company overcome these challenges and offer a solution for better air tightness in rooms using sliding doors?

Airtight systems are not new to our company and we have airtight system solutions for all different types of door variations. However, laws have changed, especially in construction where space needs to be left in the door area, and therefore we had to change things since obeying the laws is a must. Fortunately, we’ve since discovered temporary airtight solutions which when the door is pushed all the way create an airtight situation.

Airtight systems for sliding doors is a new approach because as you can imagine, the sliding operation of the doors does not allow for a completely airtight seal. We started thinking about solutions five years ago and finally came up with one just this year. 2023 was the year that we released our airtight system for sliding doors. Although we don’t have firm results yet we are very optimistic and excited about the future of this product.

Imagine that we come back and have this interview again in the year 2032. What goals or ambitions would you like to have achieved by the time we come back for that new interview?

As the president of Nakao Seisakusho, I’m trying not to focus on the size of the company, but rather on the quality of our work here. Implementing good habits and making my employees happy with their work is something that I’m working towards. If I can reach levels of satisfaction among customers and employees alike then the company as a whole is operating optimally. We are all a community here at the company and therefore if everyone is happy then we will all be mutually working towards the same goals, the kinds of goals we can achieve together. Here at our company, it is a case of quality over quantity.

0 COMMENTS