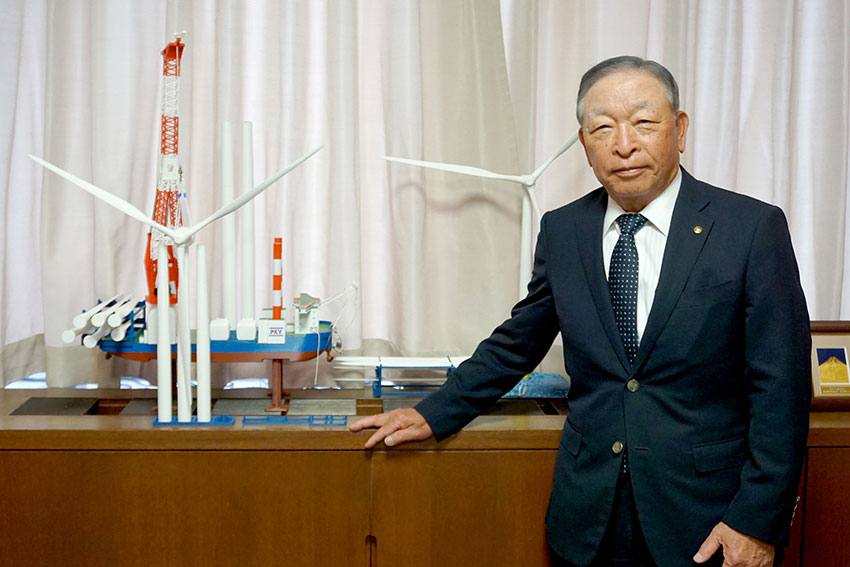

Starting as a construction company in the postwar reconstruction period, Yorigami Maritime Construction has expanded horizons integrating heavy structure work, civil engineering, and architectural works. We spoke with President Masafumi Yorigami to find out more about their latest projects, such as building wind turbine installation vessel (WTIV) for offshore wind power plant projects, as well as their new hybrid dredger and how they will be expanding their technologies to the overseas markets.

Following Japan’s construction boom around the time of the 1964 Tokyo Olympics, today we see that a lot of infrastructure and buildings works need repair and maintenance. What is your assessment of Japan’s construction market?

As you have mentioned, most of the main infrastructure and constructions have already been done in Japan. However, most of the infrastructure has been aging, so regular maintenance is essential, especially for highways and bridges.

Due to Japan’s ageing population, with 28% of the population currently over the age of 65, there is less demand for new construction projects and increasing competition between companies to hire talented young engineers. How is your business adapting to these challenges?

Nowadays, due to Japan’s workforce demographics, finding talents is getting more challenging and time-consuming. To address this issue, our company has embraced a diverse workforce in recent years. The Japanese government is easing immigration restrictions to increase the influx of foreign labor, which is an opportunity for us to attract more overseas talent, especially those from neighboring countries. Having experiences of doing business with more than 80 Singaporeans and Malaysians during my 8 years working in Singapore, I have realized the potential in foreign labor. I have no doubt that embracing a diverse workforce would increase competitiveness and lead to the company's success. Currently, we have welcomed talents from Vietnam and South Korea. We are also building up policies that offer competitive wages and benefits to appeal to more talent.

Your business is divided into three main areas. First, heavy structure work, where you engage in port and offshore activities; you even have Japan’s largest hoisting crane. Second, civil engineering, where you engage in tunnels, roads, bridges, and dam works, and third, architectural works. Could you tell us more about your ongoing projects?

Currently, our core focus is on the repair and upgrade of Japan’s infrastructure. Furthermore, we have been paying more attention to energy sector such as solar-power and offshore wind-power generation, which are trends in global construction industry but still new to Japanese construction industry. We are now having project of building wind turbine installation vessel (WTIV) for offshore wind power plant projects co-operating with Kajima and Penta-Ocean, which are scheduled to be completed in this year.

With many advantages of green energy, more offshore wind power facilities are now expected to be constructed in the future in Japan. However, as a matter of fact, when it comes to offshore wind power plant construction, the Japanese construction industry is lagging behind other overseas competitors in experience, especially those from the Netherlands. As an archipelago, Japan has a unique marine topography and meteorological conditions. With those characteristics, our priority is to establish the specialized standards of offshore wind power plant development for Japan market, based on the present standards from Europe. That is a transformation that we are aiming for in the domestic energy sector.

New building wind turbine installation vessel (WTIV)

As you look to adopt these new technologies, what role will co-creation play, including with foreign partners?

One of the strengths that we are proud of is “gemba”- on site operations, which we have utilized mainly in the construction and maintenance of bridges. Additionally, engaging in offshore wind power projects and co-operating with top general construction companies and top marine construction companies have given us valuable experiences. Furthermore, to gain competitive advantage in this area, we have been putting effort into acquiring knowledge of offshore wind power industry through our European partners’ network. We are planning and preparing our best in resource and manpower to be ready for not only domestic but also overseas project in the future

Your floating sheerleg crane Kaisho is one of the largest floating sheerleg cranes in the world. While being a huge piece of machinery, it can position bridges with an accuracy down to the centimeter, even in poor weather conditions. Are you integrating digital technologies into its operations?

Looking back to the past, Kaisho was built in 1987, when the application of technology to job processing was still an unfamiliar concept. However, Kaisho is equipped with a centimeter-level accuracy anchor system, therefore engineers and crew members play an essential role in operating this ship. With our team’s rich experiences, Kaisho has brought success to many projects, remarkably the longest suspension bridge in the world, Akashi.

Kaisho engaged in a project with wind turbine installation vessel (WTIV), a vessel that is owned by a European company. At the project, there was a monopile that exceeded the lifting capacity of the WTIV, so Kaisho, who has a larger lifting capacity, undertook the task. At first, the European company showed reluctance, as they were afraid of the possibility that Kaisho would tilt towards WTIV in case of strong winds. Such case never happened and thanks to our crew members and the anchor system, Kaisho managed to install the monopile with a high level of accuracy. That not only brought success to the project, but also filled our cooperating company with surprise.

Kaisho in the offshore wind power project

On the topic of technology, do you have any recent technological innovations that you would like to highlight for our readers?

We have developed a new technology used in our dredging operations, namely a hybrid dredger that grabs soil from under water and brings it to sand carrier. The dredger’s bucket moves up and down, and by moving the bucket, power is generated, which can then be supplied to the dredger itself. We have brought this technology to Vietnam.

Normally, dredgers require operators who manually operate the levers, however, when using our hybrid dredger, the dredger can be operated digitally. We have worked with Vietnamese and Filipino crews, and even without the experience and specific skills required, our dredger can be operated digitally 24 hours a day.

Hybrid dredger in Vietnam Project

We know that you have also conducted projects in Malaysia and Singapore. While manpower may be an issue, what has been your experience overseas and what new markets do you see your company expanding to?

In addition to projects in Malaysia and Singapore, Yorigami has been actively engaged in overseas projects in other countries. As I mentioned, we implemented dredging project in Vietnam. Currently, we have become involved in offshore wind power related project in Taiwan. It can be said that we are looking for more chances to bring our skill and potential overseas.

In the past, we used to carry out sea airport projects. However, nowadays, we are getting involved more in offshore wind power plant construction. Presently, we have received proposal of most offshore wind power plant projects in Japan. Having experiences in this new area is considered as one of our competitive advantages in the Japanese market. I believe in the future of offshore wind industry, and that more offshore wind facilities will be constructed in the future not only in Japan but also globally.

Kai Tak Airport, Hong Kong

As our business scope is in specific fields of construction, in most overseas projects, we are involved as a subcontractor, co-operating with large Japanese construction companies. When it comes to overseas project, language, especially English, is considered as a general issue. Language remains the biggest barrier for not only my company but also for main general contractors and top marine construction companies

Back in 1970, after I graduated from university, the first operation I worked on was dredging for Hong Kong’s port expansion. Then I moved to Singapore and spent many years working there. Wherever I go, I feel that the work is the same, however, it is the contractor’s ability that makes a difference. We are normally involved in the process starting from the planning phase, while financial matters are handled by the constructors. For example, our company worked on the land reclamation at Marina Bay Sands in Singapore 35 years ago. We worked with Obayashi and Penta-Ocean, contributing the required machines and vessels.

Having more than 50 years of experience working in the construction field, I understand that the success of a project depends on careful planning, attention to detail, and the contractor’s ability.

Your company has completed many projects over the years, and you possess unique technologies, especially when it comes to offshore work. Out of all the projects, which do you remember most fondly?

Among many projects of Japan’s sea bridges we have carried out, the one at Miyakojima, a beautiful island in Okinawa, left me with a deep impression. Before the bridge was built, in case of adverse weather conditions, traffic to the island would be cut off, which causes huge inconvenience to residents of the island.

Nowadays, the island has become a favorite destination for tourists, and the bridge has been selected as one of the top ten scenic spots. There is a sign put up by the residents, saying “Thank you for the bridge of our dreams”, which made me very emotional about the residents’ gratitude for our work. In fact, we were involved in the construction of 9 out of 10 top scenic spots.

Irabu Ohashi Bridge, Miyakojima Island, Okinawa, Jpaan

Imagine we were to interview you again on the last day of your presidency, what dreams or goals would you like to have achieved by then?

It has been 72 years since the foundation of Yorigami, and I will turn 75 this year. We have worked on a lot of infrastructural construction projects, with a scale as high as annual sales of JPY 70 billion. However, these days the average annual sales is around JPY 15 billion. Instead of expanding the business, I would like to build a sustainable business by developing new technologies while maintaining our own competitive advantage. By doing so, Yorigami can create a secure future for its 300 employees. That is the mission I aim for.

0 COMMENTS