integrated surface treatment specialist Suzuki High-Tech focusing on plating applications for electronic and automotive components

The Japanese famous manufacturing spirit, or monozukuri, traditionally emphasizes constant improvement in all aspects of production - but nowadays it's also about responding to customer requests and meeting new market demands. As a surface treatment specialist, can you give us your take on monozukuri and what gives Japanese firms an advantage in the marketplace?

Suzuki High-Tech was established 108 years ago. My great grandfather was the founder and I'm from the 5th generation. At first my great grandfather started making parts for small Buddhist altars that people would use in their homes. During the Meiji period electroplating technology from Germany came to Japan, and my great grandfather went to learn about this technology and brought it back to Yamagata. He was the very first person to start electroplating in Yamagata. Since my great grandfather’s time, we have been working in plating technology. However, my great grandfather, grandfather, father and all the past generations have used different types of plating technology due to the changing requirements of Japanese monozukuri.

My father’s time saw the peak period of Japan’s semiconductor production, so the majority of our income came from semiconductor plating around the year 2006. That was the peak, as Japanese semiconductor production was shifted to China, Taiwan and other countries after that. Sales also decreased, and in 2015, when I became the president, 40% of our turnover was gone. I started my tenure by developing new technology, and from 2015 to 2018 we, as a company, focused on electroless nickel plating and chrome plating that are used in EV’s and hybrid cars. The development was concluded in 2018 and since then I've invested heavily in the factory. Since 2020 we have been able to make a profit out of this newly developed technology.

It must be said that 2018 was the lowest time, when we had a 60% decrease in sales. However, this year we have the highest sales turnover so far, thanks to the technologies that have been developed recently. Currently our R&D focus is on MEMS (Micro Electro Mechanical Systems) and CFRP (carbon fiber reinforced polymers), and this next generation technology will be replacing what we currently have. I believe that my mission - and the reason why I was born into this family in the fifth generation - is to continue the business and make it sustainable. As an SME, it is crucial that we continue to pursue innovation in high technology. By developing our technology, we are able to compete with China, Korea, Taiwan and other countries.

This year we got an award at a ceremony hosted by the Nikkei Shinbun newspaper, I finished second in a competition for next generation successors between companies. When I was working on revitalizing this company, I focused on sharing my understanding with my employees. When we had our lowest sales we were very passive in terms of our business style. Since there were so few suppliers of plating, we had continuous orders but they suddenly stopped, so we had to change ourselves and change our mindset. It was very difficult. Since we have an extensive history, it's hard for us to make a big shift, especially in the mindset of our employees. That’s why I introduced diversity management.

The Japanese population is expected to be less than 100 million people by 2060. For businesses, this means a smaller domestic market to sell products to, but also in terms of recruitment, it is more difficult to get talented engineers and graduates to join your firm. In the case of your company, what have you done to offset the challenges associated with this population change?

It's a difficult question to answer. It would be a big challenge to increase the number of Japanese people, so instead we have to focus on our population and make Japanese lives more enriching, maybe through a little inflation. In fact, Japan has experienced a long history of deflation and now it's turning into inflation and because of that, I have considerably raised the wages of our employees. That's also because our sales turnover has increased. We are also focusing on welcoming foreign workers and foreign students so they can come to Japan, live in Japan, learn about our technology and work for our company.

You're going through a transformational time in your business, and you mentioned how you pivoted in 2015 when the semiconductor industry was slowly being lost to Taiwanese and Chinese makers and you switched to micro mechanical fabrication. Where is your customer base now, and to what extent have you had to look overseas, away from Japan, to target more foreign customers?

Our customers have always been domestic Japanese customers. What’s changed is that we get the items that are being produced overseas by our client, we bring them to our factory, do the plating and then return the parts to the client. The processing is done in China and the metal plating is done here in Japan by our company. That is because Chinese companies do not have the required plating technology. We're the only ones who can provide this kind of metal plating technology.

The automotive industry is seeing huge shifts both from traditional engines to EV’s and from heavier materials such as steel to lighter ones like aluminum. Can you tell us about your technology and how you're catering to the demand for lighter weight materials?

The majority of our sales income is from the plating of parts for EVs and hybrid vehicles. In power control units, there is always an amount of heat emitted. Our metal plating can dissipate heat and has the highest heat dissipation rate of any other metal plating. With EV’s gaining more popularity, more power control units will be required, so our metal plating will also always be needed.

Another area we are focusing on with lightweight vehicles is CFRP, and we are collaborating with an automotive manufacturer to apply plating to CFRP so we can add functionality to it and make it more long-lasting. We keep innovating and improving the technology so we can always cater to the market demands.

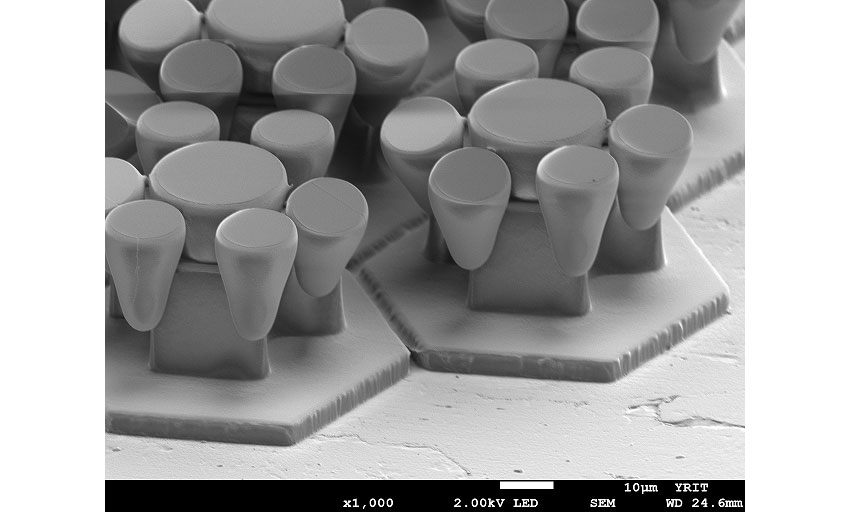

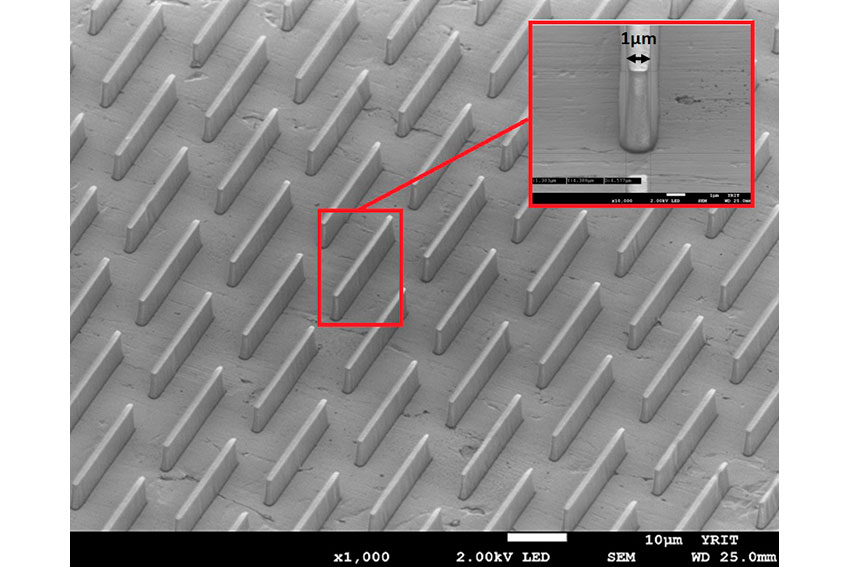

3D structure photolithography

The main focus of R&D in electronic components is largely dictated by the need for miniaturization. Moore’s law states that the number of transistors per square inch will double every two years. You’ve been developing MEMS (Micro Electro Mechanical Systems) technology since 2015, and we know you're using 3D photolithography methods to create patterns for very small, micrometer-level devices. Can you tell us how far that technology has progressed?

This technology uses electroforming and 3D structure photolithography. The diameter of a hair is 70 microns and our technology can handle objects of less than 10 microns, so it can operate on the tiny parts that we want to utilize for life science and medicine.

technology micron-based demonstration

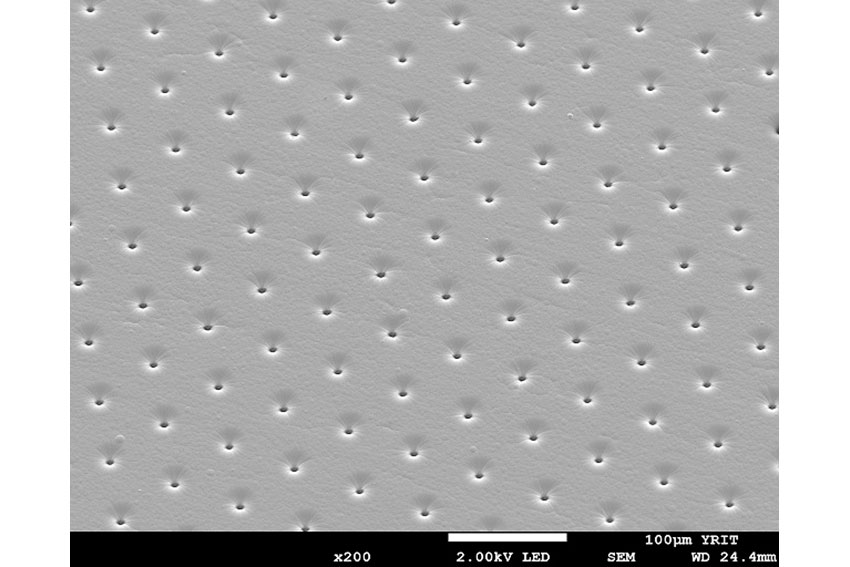

We are developing mesh to be mounted on a medical spray device using our unique microfabrication technologies. The development of the core technology is complete, and commercialization is under way. Our mesh delivers a mist containing particles of three to four microns, which is the smallest in the world. The spray can go direct to the affected area, and the device only requires a AAA battery to work.

In the space of six millimeters, we have made 7000 holes of three microns in width. The resulting mesh can only be created with our technology. With our innovation and invention, we are able to help advance health care. We are currently applying for a patent for this technology.

mesh for medical spray device

We are currently focusing on the medical industry - in the home treatment area especially - and we want to innovate and develop unique new technology to the world that uses our MEMS technology and plating technology to cater to growing medical needs.

You have ambitions not only in the medical industry but you are also looking to focus on CFRP for robotics in the aerospace industry. Japanese companies are very famous in these two industries. 35% of the Boeing 787 parts, for example, are supplied by just two Japanese companies. Are you looking for co-creation projects as you look to enter those industries or partners overseas that can help you further enhance your presence in those industries?

In terms of CFRP, we’re currently working with CFRP material manufacturer on robotics. We have been working with Japanese robotic manufacturers. On the medical side, we’ve collaborated with other companies, but they are all Japanese manufacturers and we want to turn to overseas partners to collaborate with too, of course.

We currently have some collaboration work going on in the power device field with a European company, but not yet with CFRP, robotics or medical so we want to extend our reach to overseas companies as well.

The reason why we are hiring foreign engineers is because we want to collaborate with overseas companies. Japanese people are not very good at English. Engineers are particularly reluctant when it comes to speaking English, so we have hired foreign workers from overseas.

We need to increase awareness of our cutting-edge technology among other global companies. We need to highlight the new things they could do with our technology, but we're not very good at conveying that message. I can understand English but I cannot speak it very well, although my brothers are very good at it.

Achieving uniform plating on all surfaces of some shapes such as cylinders and tubing is a very difficult thing to do. These tubes can be critical components in suspension, piston and brake caliper assemblies, and they could fail if there's corrosion inside. Can you explain how you were able achieve such uniform plating inside of a tube, and what are some of the key applications you use this technology for?

This technology is unique in the world, and it took three years for us to develop it, altogether, and it was a trial and error process. Our hard chrome plating is used mainly to increase the fuel efficiency in hybrid combustion engines. I think we're the only company which has the specialized technology to perform hard chrome plating inside components.

metal plating line for hard chrome plated fuel nozzles used in hybrid engines

Japan’s automotive industry has famously had a keiretsu model of Tier 1 and Tier 2 suppliers who supply automakers. This model is very hierarchical in structure and some commentators believe this prevents new companies entering the supply chain. Now of course, the automotive industry is transitioning, and new companies and startups are appearing in China, Europe and the US as barriers to entry lower. When the Japanese automotive giants are challenged like this, how will you appeal to these new players entering?

The dismantling of the keiretsu model has given us a big opportunity. This trend began a little bit before I became the president. With the development of new technology, we were able to serve automotive companies thanks to the breakdown of the keiretsu model. Before that, we did not have any automotive manufacturers as clients, but following that, we were able to work together with domestic clients which evolved into overseas clients as well. I'm sure there are more opportunities to come, both domestic and overseas, so it's crucial for us to continue developing our new technology and always focus on our marketing style so that we can identify new demand and cater to those needs. The recent growth in our sales turnover is thanks to EVs and hybrid cars.

The reason why we were able to succeed in the automotive industry during the shift to EV’s was the speed with which we were able to respond to changing demands in R&D and manufacturing. Other companies within the keiretsu system were not flexible enough within that framework so we, as an independent metal plating company, were able to meet the needs of the changing market with flexibly and agility.

You’ve had international operations in China since 2012, and in Mexico since 2014. Moving forward, where will you expand to next? What is your strategy in terms of the international market?

It depends on the field, but for automotive we would like to focus ourselves in Mexico and centralize our operation there. We also want to find an agent hub, but not in China. In China we are focusing on smartphone metal plating, but for automotive, maybe India would be a potential candidate. We are still at the research stage, which we’re conducting jointly with overseas companies. In terms of robotics and automation, it's more European and American companies. It's German, French and US companies that we would like to collaborate with.

Let's say we come back to interview you again on the last day of your presidency. What would you like to tell us about your goals and dreams for the company by that time, and what would you like to have achieved by then?

The sole reason for the company to exist is to contribute to domestic and global society. It's crucial that our company continues to contribute to the development of society and the welfare and happiness of society. Of course, the employees need to be happy, so as a company president I would like to continue to create an environment to make the lives of employees more enjoyable and happy. I'm currently 52 years old, so the longest I will be president would probably be about 15 years. I want to pass the baton down to the next generation, but I also want the company to be needed by society and I want it to be seen as a crucial component of society. My child is still only 20 years old, so I have a long way to go.

0 COMMENTS