Biomass Energy Corporation has been working on perfecting biomass generator technologies that combine gasification, liquid fuel (methanol) synthesis and power generation for over a decade. Such efforts enabled the company to finally launch its groundbreaking technology to the market in 2018. We speak with president Mitsunori Hiramoto to learn more about BME’s biomass generator, which can use a wide range of materials as fuel sources, from grass, bark and leaves, to waste products of coffee and beer production.

Biomass Energy Corporation was founded in 2006, Could you please highlight the key milestones of your company?

Even though we were founded in 2006, our history has begun in 1990s. At that time, we invited Dr. Masayasu Sakai, our current chairman, to lead our research and development effort to realize a cleaner and more efficient biomass generator. Dr. Sakai was a professor at the Nagasaki Institute of Applied Science. During his tenure, he developed the “Agricultural Biomass 3 plant”, the first prototype of our current biomass generator, in a program fully funded by the Ministry of Agriculture, Forestry, and Fisheries. This is where the underlying technologies that combine biomass gasification, liquid fuel (methanol) synthesis, and power generation were first realized. Also, he previously led the development of Mitsubishi Heavy Industries’ biomass gasification technology.

Ever since, we have been working to improve the adaptability, usability, and underlying technology of our product over the course of a decade. In 2018, we brought our first gasification generator plant to market.

BME’s core business is biomass gasification and liquefaction technology. Could you please explain more about this matter and what is BME’s competitive advantage?

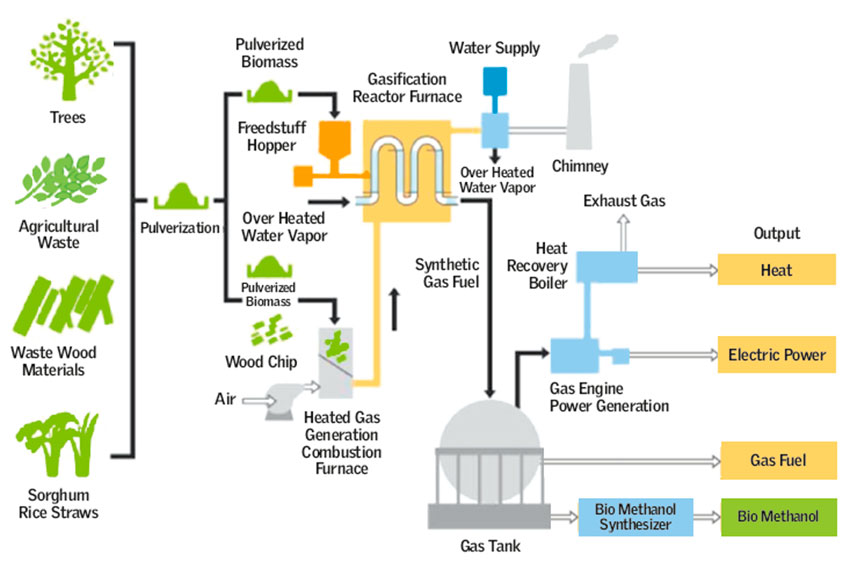

Most products from Europe can only use plain wood as fuel resources; predominantly pellets or chips. However, we have developed a product that can use a wide variety of fuel sources, such as scrap wood, grass, bark, leaves, and branches, or even the waste of beverage products such as tea, beer, and coffee. These fuel sources are not only abundant and cheaper to procure but are in fact waste products, that would otherwise cost money to dispose. So, we are able to utilize the waste for better functions.

What are the on-going trends in this field that you are able to share to us?

Amid concerns over fossil fuels, methanol is now being recognized as a fuel for automobiles and tankers once again. Our CO2-free biomass methanol production technology foresees the world without fossil fuels, and it is in high demand on the market.

What are the challenges that your company has tackled in the industry?

The challenge, however, is that these fuel sources such as scrap wood and beer, give off far more contaminants than plain wood, which is generally clean. For example, scrap wood near seawater tends to contain a large amount of salt that has been absorbed through its bark over time, when incinerated to gas form, especially when the gas is then cooled. There is the risk of harmful dioxides being formed as a byproduct. While beer waste products tend to contain a large amount of natural nitrogen, which when burned produce hydrogen cyanide (HCN), another harmful byproduct. Similarly, burning sawdust can lead to its ashes transforming into silica crystals (cyclabilities) when exposed to high temperatures. Much of our efforts were also focused on the development of efficient water or air-cooling systems for removing tar, an unavoidable byproduct of biomass energy production.

After overcoming countless obstacles, and more than 10 years of devoted research and development, we have been able to find solutions to all these issues to create a product that can finally be brought to market.

There are many new projects in the field of biomass, and various initiatives have been applied, due to the increased efficiency of biomass energy generators and a slight decrease in implementation cost. What is the distinctive feature of your technology among other projects?

What may be unique about our technology is that it is in fact not so much focused around biomass gasification itself. It is around the generation of high temperatures required for gasification, such as the combustion technology.

Conventional combustion furnaces contain an area where fuels are burned, known as grates or stoker, and these have issues such as ash treatment of clinkers, or the particles formed by melting ash, or excessive ash. Meanwhile, materials such as bark or straw, which have low melting points, pose issues.

To solve these issues, BME installed the methods such as making biomass materials into powder (>10mm); 3D combustion by circulating the powders in the furnace (developed original compact furnaces); making the furnace into a radiant heat burner by keeping the furnace wall around 1000°C; also proceeding with continuous operation of the ash collection system and clinker removal system. These methods allowed us to combust any kind of biomass more than 1000°C under auto control. Also, we made gasification happen in a reactor in oxygen-free condition by using its heat as external heat. We strive to further develop this technology and let it come to wider usage.

Are you performing factory automation for your system?

Currently, we are able to perform gasification power generation by full automation. However, we still need more manpower to carry materials in order to prevent it from getting clogged. Our system never drains water and its exhaust fumes conform to the environmental standard set forth all over the world.

In 2013 you went beyond the Japanese border and established a subsidiary in Singapore. Can you tell us more about your international strategy?

Even though Europe historically took the lead in the development of biomass technologies, we went to Singapore in 2013 and our first plant for commercial use was developed in 2016. Since then, we have been testing various biomass fuels originating from Southeast Asia.

How you would like to contribute to society with the technology that you possess?

Our original measures and methods allowed us to use cheap wood, leaf including waste disposal. We would like to make the most of this one-and-only technology, such as a furnace which combusts anything and a gasifier which gasificates anything. No matter where it is, we can change any materials into energy as long as you have biomass. That’s the way how we would like to contribute to the society in a SDDGs way.

0 COMMENTS