In the heart of Japan's industrial landscape, Ryuki Engineering stands tall as a beacon of innovation and reliability.

The Japanese industry is at a pivotal juncture, having experienced significant supply chain disruptions from COVID-19 and the US-China decoupling. Consequently, corporate groups are seeking supplier diversification for reliability. Japanese firms, renowned for reliability, advanced technology, and a weak Japanese yen, are seen as being in a unique position. Do you agree with this assessment of a unique opportunity for Japanese firms? What advantages do you believe Japanese firms possess in this current macro environment?

Given the rapidly evolving global situation, we believe this is an important time to review our strategy from a global perspective, including Japan. We see this trend of yen depreciation as a great opportunity for our company. Recently, we have been receiving many contacts, especially from Chinese, Taiwanese, and Korean companies, and we feel that we are being affected by the weak yen.

Excluding the automotive industry, manufacturing in Japan is no longer confined within the country’s borders and is transitioning towards providing high-quality products that can only be manufactured in Japan. Therefore, we believe that Japanese manufacturing will continue to play an important role from a global perspective.

In our case, our focus is on providing universal solutions that effectively address common social issues, while acknowledging the differences in business cultures and traditions in each region. Over the years, we have developed deep relationships with general contractors in the construction industry.

We also provide the same level of equipment leasing and consulting services as we do in Japan for overseas projects related to Official Development Assistance (ODA), specializing in manufacturing, and selling finished products, with no supply chain influence, such as providing parts or modules.

The company's business structure includes the rental of ventilation and dust collection systems for tunnels and other construction sites, as well as tailor-made solutions for other markets.

In the rental business of dust collectors and other equipment for tunnels, we provide the most suitable machines by owning equipment designed and manufactured in-house and providing consulting services, including equipment selection, to meet the challenges of each project. In tailor-made solutions, we design, manufacture, and sell machines based on specific customer requirements. Areas of service include aerospace, aviation, nuclear power, defense industries, public works, manufacturing, soil and groundwater contamination, various recycling plants, and many other industries.

Dust collector to process dust from blasting in tunnel

The demographic shift towards an aging society with a rapidly shrinking population has notably impacted Japanese society, particularly in the construction sector, where one in three workers is already over 65. This situation poses labor challenges as a smaller pool of graduates is available for companies to replace their aging workforce, coupled with a contracting domestic market. How has this demographic shift specifically affected your firm, and what strategies have you implemented in response to these challenges?

Fortunately, we haven’t experienced significant impacts because, as mentioned earlier, we have a wide range of offerings and are not dependent on the construction industry.

As you noted, the construction industry faces unique challenges such as labor shortages and an aging workforce. In response, we are innovating to improve the working environment and increase efficiency through labor-saving and automated technologies by developing new types of machinery for rental within the construction industry.

We are also working to mitigate the effects of labor shortages at construction sites by implementing IoT and digital solutions.

Our company engages in business activities that contribute to solving global environmental challenges, as outlined in the SDGs. This attracts young talent, making it easier for us to recruit skilled individuals without encountering major challenges. Additionally, we strive to provide a work environment where they can pursue their passions and aspirations.

Employee satisfaction is a key factor in the success of our recruitment strategy and allows us to aggressively expand our presence within the industry.

Are there any emerging industries or applications where you're considering introducing your products and services beyond your current market scope?

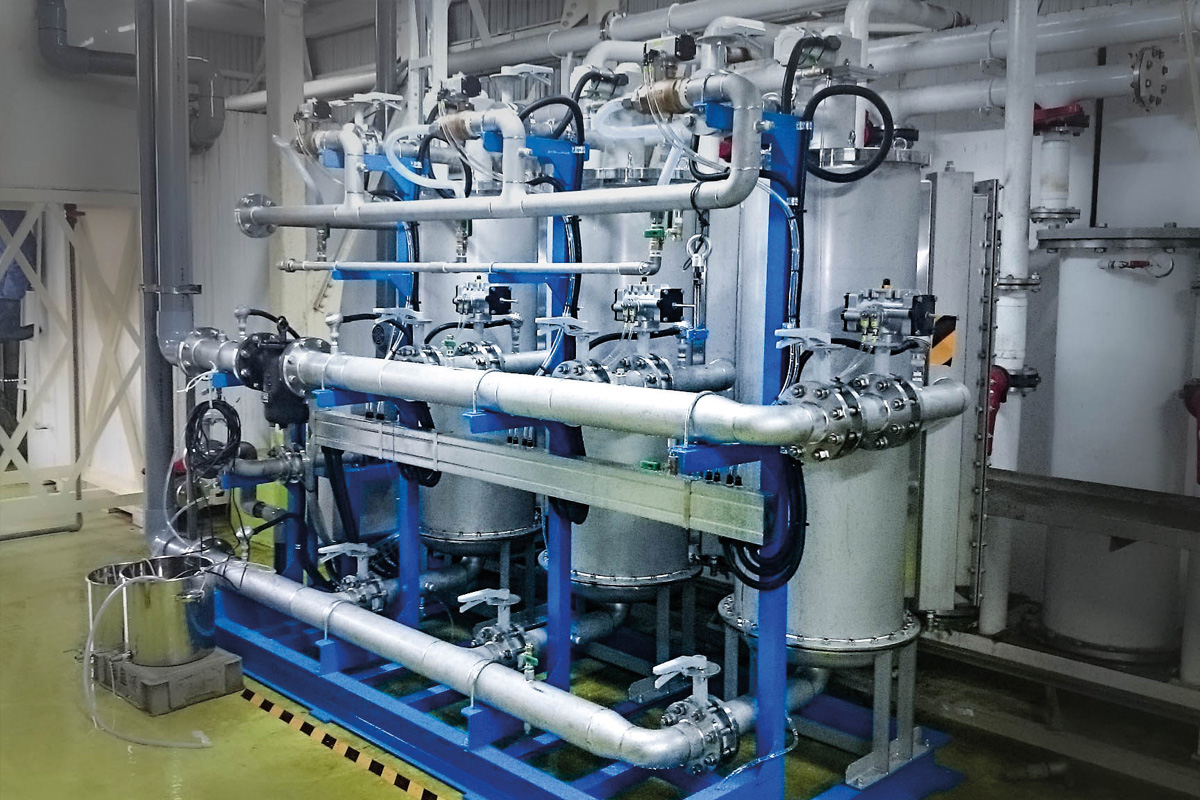

Our main focus is on expanding our overseas business segment. As a new challenge, we have directed our focus to the treatment of PFAS, which has become a significant issue not only in Japan but also in developed countries like the U.S. and Europe. Recently, we developed a technology named Liquid, Filter, Powder (LFP), which we believe is optimal for PFAS treatment. By implementing this technology on a macroscopic level and combining it synergistically, we successfully proposed a solution in Okinawa. The technology gained considerable attention both in Japan and internationally, leading to increased contact and interest in our company.

Our LFP technology was selected by the Ministry of the Environment as a target technology for the "Low-cost, Low-impact Soil Investigation and Countermeasure Technology Study" in FY2023. If the effectiveness of the LFP technology is proven in this project, we will be able to offer our products as a publicly recognized technology.

Large dust collector (3,000 m3/min)

The LFP method, a treatment process involving the creation of thin layers of functional powders to remove contaminants, is currently undergoing verification of its effectiveness in a project by the Ministry of the Environment. Do you foresee this method becoming the industry standard for such treatments?

We developed this product based on three very important concepts: accuracy, efficiency, and cost-effectiveness. Of these, cost-effectiveness is the most important factor. While many technologies exist to address this issue, cost has often been a major barrier. As mentioned earlier, our product has been adopted for investigation and is currently being tested according to a program approved in consultation with the Ministry of the Environment. The testing criteria prioritize proving solutions that are field-applicable, cost-effective, and environmentally friendly. Because our product meets these criteria and has strong government backing, we are confident in bringing our solution to the forefront of the market.

Do the ECO clean and your unique pleated filters leverage the LFP technology for their functionality?

The foundation of the LFP is the ECO Clean. ECO Clean utilizes pleated filters with a larger surface area compared to filters of the same size. In addition, since surface filtration is possible, powdered activated carbon can be attached to the surface and used as an LFP filter.

The system also requires a much smaller footprint than a similar system with the same amount of treated water.

Among the various projects where your technology has been utilized, both domestically in Okinawa and internationally in Asia, Europe, and Africa, is there a particular project that stands out to you as the most prideful or personally favored?

To reiterate, we provide solutions in a wide variety of areas, including aerospace, aviation, nuclear power, defense industries, public works, manufacturing, soil and groundwater remediation, various types of recycling plants, and more.

For overseas projects, we have exported dust collectors for steel mills and chemical plants, as well as supplied dust collectors, ventilation fans, and cooling systems for hydraulic plants required for the construction of railroads, road tunnels, and other infrastructure facilities.

I take pride in my work as I participate in projects that "remain in shape" across various locations, delivering machinery and equipment that contribute to improving both natural and working environments.

The most memorable project I was in charge of was my first assignment after joining the company. I was dispatched to the JAXA Space Center on Tanegashima. Our assignment was to provide nitrogen purge coatings, in essence, protective covers for various components. Tanegashima is home to several facilities that store rocket engines, rocket bodies, and satellites. Because Tanegashima is exposed to sea salt and frequent rainfall, it was critical to produce precise and reliable covers for each item. However, we succeeded in achieving this by employing an automatic cover system that uses air pressure to separate and join the covers, despite the technical challenges involved. Our hard work was rewarded with high praise from the customer.

Another important project was a test facility for offshore floating wind turbines. Our task was to deliver an offshore test facility that could simulate an actual wind turbine.

We also designed and built a large vacuum cleaner for maintaining artificial turf, which was not available in the market at the time. The nozzle technology, which took more than two years to develop, played an important role and resulted in a patented technology.

ECO Clean LFP for PFAS treatment

In your efforts to expand your technology into overseas markets, could you provide details about the strategies you're employing to achieve this goal? Are you considering partnerships to navigate local regulations and better understand the dynamics of the local markets as part of your strategy?

We have launched a new overseas strategy through alliances among Japanese companies. Several companies have joined forces to establish local distributors and stores overseas. The first was in Shanghai, China, where we provide comprehensive consulting services aimed at achieving an optimal environment, including environmental education, factory safety diagnosis and analysis, and the proposal and sale of environmental equipment. We started in China first, but in the future, we would like to expand this business model globally.

We have also found success in other areas overseas by working with local partners to provide environmental solutions in mountain tunnels. We supply parts and equipment through our partnership with a Chinese company, who are deeply involved in providing tunneling equipment. They integrate our products with theirs to meet the specific local needs. Compared to Japan, China significantly lags behind in the civil engineering field. The local environmental conditions are harsh, so supplying the right equipment together with local partners who are familiar with the specific challenges is an advancement for us. Moreover, our cooperation extends beyond China to the rest of the world, with our technology being deployed from our South Korean base and gradually expanding to other Asian countries. In the meantime, we are continuing discussions with an American company for a business partnership regarding PFAS water treatment methods.

If we were to revisit today, a decade from now, what specific goals would you, as the President, like to have accomplished within the company by then?

Our mission and values are to address the social challenges of today's environment. We focus our research and product development efforts toward this purpose. Technologies such as dust collectors, VOC treatment, and water treatment are the result of pressing social needs. We are constantly seeking solutions to existing and future problems by remaining progressive. Currently, we are focusing on developing advanced technologies to address new issues such as CO2 and NOx, which are expected to become major problems within the next decade.

Cost-effectiveness, as well as effective technology, plays a crucial role in achieving a sustainable society, and the SDGs emphasize not only environmental recovery but also economic and social sustainability. Therefore, our products must be both environmentally friendly and cost-effective. In order to contribute to the creation of a sustainable society, we aim to satisfy all stakeholders, including ourselves and our users. Pursuing economic efficiency along with technological advancement is an ongoing priority for us.

Research and development involve constant trial and error, often accompanied by failures. However, with each setback, we can gain new perspectives and valuable lessons. The accumulation of such experiences reinforces our determination to ultimately succeed in addressing social challenges. While we cannot predict exactly when our developments will yield results, our determination remains unwavering.

0 COMMENTS