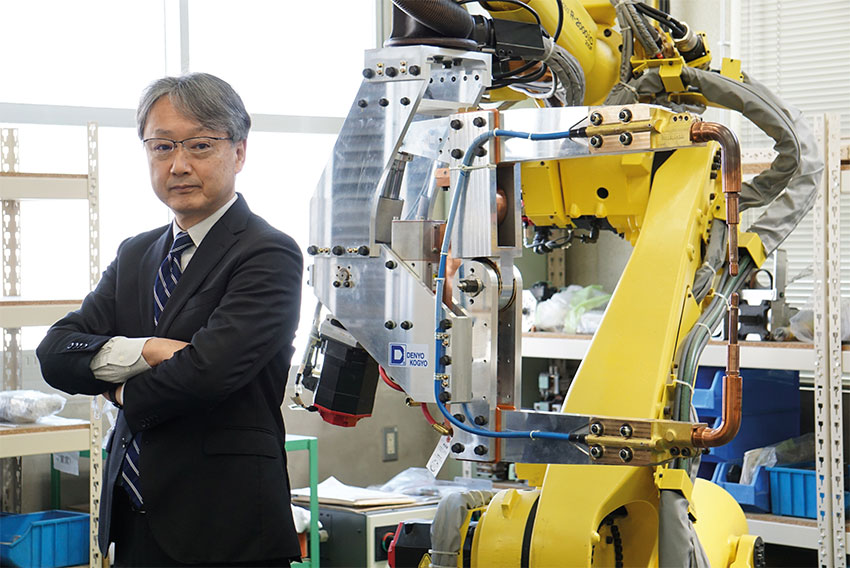

As the needs of automobile manufacturers have become increasingly diversified, there is an increasing demand that the resistance welder used in production be smaller, lighter, and faster. For more than half a century, Denyo Kogyo has responded to the ever-changing needs of the automobile industry, providing cutting-edge technology in resistance welders for leading manufacturers in Japan and around the world. In this interview, president, Akio Nakamura, explains how Denyo Kogyo has embarked in two major fields of R&D in response to the materials revolution in the industry, and the trend towards making cars lighter and more fuel efficient.

Could you please tell us about your assembly plant and how you make the cast?

We want to retain the technology that we have developed and use that in making the component parts. Each casting part is handmade because in most of the cases, our customer has their own specification that is unique and “only one”, therefore, everything has to be customized. Of course we are using lightweight materials such as aluminium in responding to our customers’ request for lightweight, yet this customization is the strength of SMEs and is something that big companies simply are not capable of doing.

This customization is the strength of SMEs and is something that big companies simply are not capable of doing. Our plant is unique because we do not have an assembly line, each of our products is uniquely developed and each person involved in the assembling process takes responsibility for his assigned task.

How do you maintain the quality of your products for your international market?

We conduct training sessions either by sending our Japanese engineers to teach foreign engineers working at our factories overseas or by having them come to Japan. We also dispatch our very own Japanese engineers to maintain the quality of our production process outside Japan. In fact, each month last year I was traveling overseas to oversee our factories and to ensure that everything is of the highest quality.

Compared to other companies, most of your staff are relatively young despite Japan’s aging population. How are you able to attract young, talented graduates to your business?

We had struggles inviting younger people to our company. One major change that we made last year is we now have our satellite office in Nagasaki. Yamanashi, which is where our headquarters is located, is considered a risk area because it is prone to strong earthquakes and it is close to Mt. Fuji. Our office in Nagasaki is for the design process, hopefully we will have our production site there as well. Nagasaki Prefecture is very welcoming and thanks to them we were able to hire young staff members. It is hard to find young people to work around the Yamanashi area because it is close to Tokyo and Kanagawa and young people tend to go to these cities. The reason why Nagasaki Prefecture is actively supporting us is they want to create better job opportunities for these young people, they want these young people to stay and not move elsewhere.

Can you tell us which known companies use your products?

We supply our products to major Japanese automakers. We deliver many of our products to Ohio, USA. There are many other tier-one companies in Ohio as well, actually. A Minister from the Indian Embassy came to see us because we work closely with a Japanese automaker in India. They have a huge share in the Indian market, 50% of the cars in India are made by them. So we established a factory in India since our products are used by them.

Our strength is being capable of customizing the parts that we supply according to the needs of our customers and that is something that big companies cannot do.

Can you tell us a bit about your business in China and India?

Japanease major automakers are proactively increasing their production platforms overseas and promoting local productions. In order to respond to their needs, we also have been enhancing local production, sales and services overseas. Countries such as the US, China, and India are huge and invigorated market for automobiles. Auto sales in China passed the US and now is No.1 in the world. India is expected to grow steadily in auto production and sales. Since the workers are diligent and highly competent in those countries, we decided to run local production there and have been conducting production and sales of our products there.

Traditionally, Japanese manufacturing involves the relentless pursuit for perfection and this was defined as monozukuri, but nowadays the modern version of monozukuri involves responding to customers’ requests and providing added value to the products delivered. How do you define monozukuri and what is the essence behind it?

The basic foundation of our monozukuri is craftsmanship. In the past the craftsmen who specialized in a specific field whether in designing, manufacturing, or assembling stage, they took responsibility in improving their skills or the things that they produced and they do this with passion. Since our business model is to be able to respond to the specific requests of our customers, we have to be flexible in designing, manufacturing and assembling. We give importance to the demands of our customers and it is our job to meet them.

Robotics is often viewed negatively as replacing humans and putting people out of jobs. However, when we spoke to Dr. Inaba, the founder of Fanuc, he interpreted robots as complementing human labor and allowing human resources to be redeployed to other parts of the business such as sales or accounting and a means of upskilling staff and providing new opportunities. What is your take on robotics and why is Japan a leader in this sector?

The Japanese robotics companies are very competitive in the world mainly because of their advanced technologies with excellent quality. Robots are not there to replace human labor, but they are invented to improve the services and manufacturing processes which could make us more productive, I believe robotics has been making revolutionary change in welding technology and processes. Back in the day workers needed to operate heavy machinery but with the introduction of robots it has brought convenience and comfort to the human labor force. Welding was a tedious and a messy work, not to mention risky, and was not favorable to health conditions, but now it can no longer be a physically demanding job with automation.

Ninety-five percent of your products are used by the automotive industry. If you look at this industry there is a big transition to EV taking place which will require new lighter materials to be used to offset the weight of heavy batteries. As a result, manufacturers need to develop materials used for cars that are lighter and at the same time stronger. How is your company adapting to this material revolution that is taking place in the automotive industry?

With regards to the material revolution that is happening in the automotive industry there are car manufacturers that use aluminium for their high-end cars and they can use our welding technology. With regards to CFRP (Carbon Fiber Reinforced Polymer) our customers are trying to figure out how they could utilize CFRP for the bodies of their cars. At this moment we believe that the cars will not be fully carbonized just yet and steel would still continue to be used. We are looking into other ways where we could use our welding technology for these new materials that need to be attached to the cars. We are working with a steel company to develop a technology to attach steel and other types of metals such as aluminium and CFRP. It is imperative for us to evolve our technology to adapt to these changes. We are trying to look ahead into the future and determine which path our company has to take.

We have seen that Japanese companies are increasingly engaged in co-creation with foreign partners to come up with new innovative technology. What role does co-creation play in your business? Are you looking for a co-creation partner at the moment?

Actually, we are receiving requests from other companies that would like to partner with us for co-creation purposes. We believe that if we diversify the use of our machinery more people will notice us. We are now looking into each request and finding ways in which we could collaborate and come up with something new that addresses the needs in the market

Your products can be split largely into four different types of guns: Your C gun types; your X gun types; your S series and your M series. Kindly tell us your best-selling product and synergy have you been able to create between these distinctive yet similar guns?

Every single product that we have is selling well in the market because we work closely with our customers, the products that we developed are based on the request of the customers. Basically, each client has their own concept of their assembly line and based on that we develop new products that suit their concept.

When we think of Japan as a country that manufactures, we know that a huge percentage of GDP is spent on R&D. According to the World Bank 3% of Japan’s GDP goes to R&D. Can you tell us about your R&D strategy? What products would you like to share with our international audience?

Our Research and Development division is currently focusing on integrating sensors on our welders, and also for the automotive industry we are looking for solutions to make the body lighter by producing thinner but harder steel. High precision is absolutely required on the part of the welders. Several automotive companies have approached us in making this improvement and we are now developing a sensor that could control the pressure or force applied by our welders. This is our major project right now which aims to improve the accuracy and the quality of our machinery and at the same time increasing the speed while making our products lighter.

Production in the automotive industry is steadily rising after the Covid downturn last year and it is predicted that by next year 84 million cars will be manufactured globally. How are you adapting to this increased demand?

Since Japan’s population is declining the demand for cars will keep decreasing unless the society fully shifts into using cars with self-driving capabilities. Nevertheless, there is higher demand in emerging markets such as in China and India. Our factory in China is now working at full capacity; in India it is almost there. On the other hand, our business is not dependent on the number of cars produced because our products are used in the facilities, it does not matter whether these car manufacturers that we work with produce more or fewer cars, although an increase in the assembly lines means an increase in demand for our products. Lastly, to increase the capacity of our offices and production sites overseas, we give training to the engineers assigned there.

You have been abroad since 2001 when you established a company in China, the US in 2005, India in 2007, and Thailand in 2014. Can you tell us more about the advantages of this integrated sales and production approach and what benefits does this bring to your company?

As regards our international strategy, we established factories in India and China to make our products in these local areas and sell them in these markets, and by doing this we still apply the Japanese model which is an integrated production system. We use the same model in all of our factories around the world. We do not do what other Japanese markets are doing where they manufacture their products in China for a cheaper cost and then sell these products in the Japanese market. Another strategy that we have is we manufacture the common parts in China and then distribute that to India and Japan as part of efficiency.

We, as a company, believe in the importance of localization. For this reason, we supply our products to tier-one manufacturers in the local area, especially ones that have the technology, know-how and the foundation to cater to the needs of the local manufacturers. We know that Japan is the frontrunner in the automotive industry, and we were able to build our brand in Japan. Our company has become known already, therefore, when we take this brand to emerging markets such as in China and India, they are already aware of our brand and that is a huge advantage for us.

Speaking of international expansion, what markets are you looking to export your products into? And how will you do it, will you do M&A, joint-ventures or open up a new office or factory?

I have already mentioned that we are doing well in the Chinese and Indian markets, however we believe that in the future the market will become saturated. We are now looking into Africa as a potential option, and we are kind of interested in infiltrating this market. We created our factory in the west of India because the transportation to Africa would be easier. We do not have experience with M&A because this is not part of our approach in conducting our business, most probably when we expand overseas, we would establish our own company there.

We are currently looking for more customers in the market that we are already in since there are a number of tier-one companies that we have not worked with yet - such as GM and Ford in the US. Fortunately, in China we were able to work with local manufacturers and we want to increase our customers there. Lastly, Europe is also another market that we plan to penetrate into.

Imagine we will come back to interview you again in five years, what would you like to tell us? What are your dreams for the company and what would you like to have accomplished by then?

In five years’ time I would be very glad to invite you to see our factories in China and in India. I would like Denyo Kogyo to be working with more top companies in the domestic and international levels. To be active in a number of countries is something that we look forward to as well. With our continued quest in developing cutting edge technology, we would be able to meet the needs in the market and make our clients happy.

0 COMMENTS