Africa could potentially skip the second industrial revolution – traditional manufacturing – and leapfrog straight into digital manufacturing (or 3D printing as it is commonly known).

Last year a young entrepreneur and inventor from the small West African nation of Togo made history by creating the first ever 3D printer assembled from e-waste. At a scrap yard in Lomé, Togo’s capital, Kodjo Afate Gnikou spent weeks foraging for leftover computer, scanner and engine parts to construct his DIY 3D-printing machine. Costing just $100 to build, this innovative machine can be used to manufacture simple plastic objects such as food containers and other household wares, while also tackling the growing problem of e-waste.

This is merely one example of the ever increasing level of technological innovation happening on the continent. Africa has already shown its incredible ability to leapfrog older forms of technology in favor of the latest. It skipped the traditional landline, first and second generation mobile phones, and dialup and ADSL internet, moving straight to third and fourth generation mobile broadband technology. Now it looks ready to leapfrog the second industrial revolution – traditional manufacturing – and move straight to digital manufacturing (or the third industrial revolution as some have hailed it).

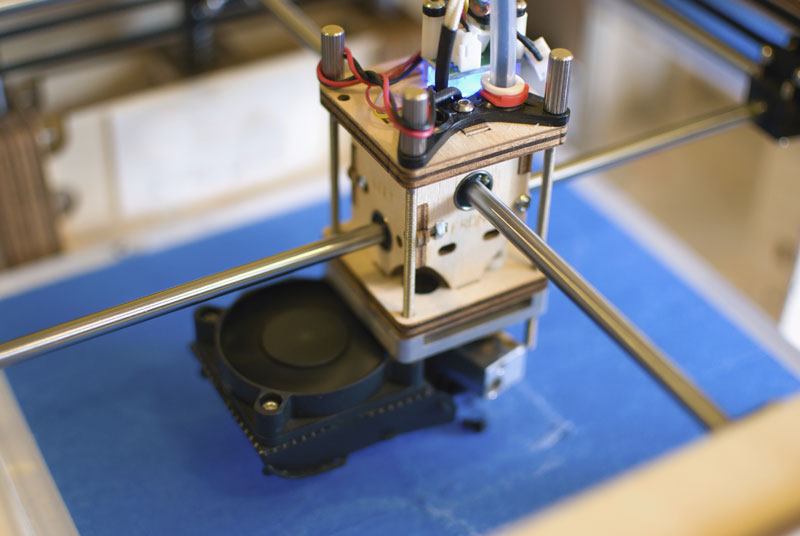

Digital manufacturing, or 3D printing as it is more commonly known today, has been around since the 1980s, yet it has only gone mainstream in the last few years thanks to technological advances. For those not in the know: it involves the “printing” of three-dimensional objects by a special printer which constructs objects layer by layer. Up to recently, the machines were only able to print parts made out of a special compound material, but now 3D printers can produce objects in plastic and a wide range of metals . They are now even being used to “print” clothing (in September 3D-printed fashion hit the runway in New York).

Digital manufacturing could potentially revolutionize the manufacturing industry in Africa in a way that smartphones and mobile broadband are transforming the services, trade and agriculture sectors. Mobile broadband technology is giving millions of Africans access to vital services that were never before available to them, particularly health, education, banking, and government services. It is being used to improve efficiency and service in trade, commerce, and even agriculture (iCow for example, an innovative app created in Kenya for Kenyan farmers, maximizes breeding potential by tracking the fertility cycle of their animals).

The lack of an established manufacturing industry in Africa means most states rely on costly imports of items such as building materials, machine parts, tools and household objects. As 3D printing technology becomes more versatile, advanced and accessible, African nations could digitally manufacture such objects domestically, thus reducing dependence on costly imports and bringing major benefits to their economies. This would also create a thriving new industry that doesn’t require the factories, machinery, labor and capital that traditional manufacturing does.

Enterprising inventors like Kodjo Afate Gnikou could purchase or build their own 3D printing machines, set up local 3D printing shops where they could sell objects made to order to household customers (thus reducing waste and eradicating the problem of unused inventory). Construction companies could use 3D printers to produce the materials they needed to build and fit houses; technicians and mechanics could digitally manufacture car parts, machine parts and tools, using raw materials mined locally. The level of innovation could skyrocket as carbon copies of scientific equipment could be “printed” for a fraction of the cost, giving labs and research centres on the continent access to technological instruments that they could only dream of affording in the past. The possibilities truly are endless.

Digital manufacturing already has benefits outside the economic realm. Considering the large number of amputees that have been victims of brutality, war, and disease on the continent, perhaps the most important use of digital manufacturing in Africa will be to create fast custom-made, yet inexpensive, prosthetic limbs.

This process is already underway: in January, Critical Making Lab owner and Toronto University professor, Matt Rotto, began working with CBM Canada (an NGO), Autodesk Research, and CoRSU (a rehabilitation hospital located in Entebbe, Uganda) to supply cheap digitally-manufactured limbs for child amputees in Uganda. Last year Mick Ebeling, an American entrepreneur and philanthropist, set up the world’s first 3D-printing prosthetic lab and training facility in Sudan. The lab’s first success was the construction of a prosthetic arm for a teenager whose arms had been blown off two years earlier. This is really just the beginning of how digital manufacturing could transform healthcare in Africa.

Kodjo Afate Gnikou’s $100 homemade 3D printer assembled from e-waste is a successful demonstration of how this process can increase economic development in the developing world. However the Togolese inventor, who won the NASA International Space Apps Challenge last year, has a much more ambitious project: sending e-waste to Mars to construct habitats for humans.

“My dream is to give young people hope and to show that Africa too has its place on the global market when it comes to technology,” he says. “We are able to create things, why is Africa always lagging behind when it comes to technology?” With the number of innovative creators like Kodjo on the rise on the continent, and the further adoption of technologies such as 4G mobile broadband and digital manufacturing, Africa may not be lagging behind for long.

By Jonathan Meaney, Worldfolio staff writer

0 COMMENTS