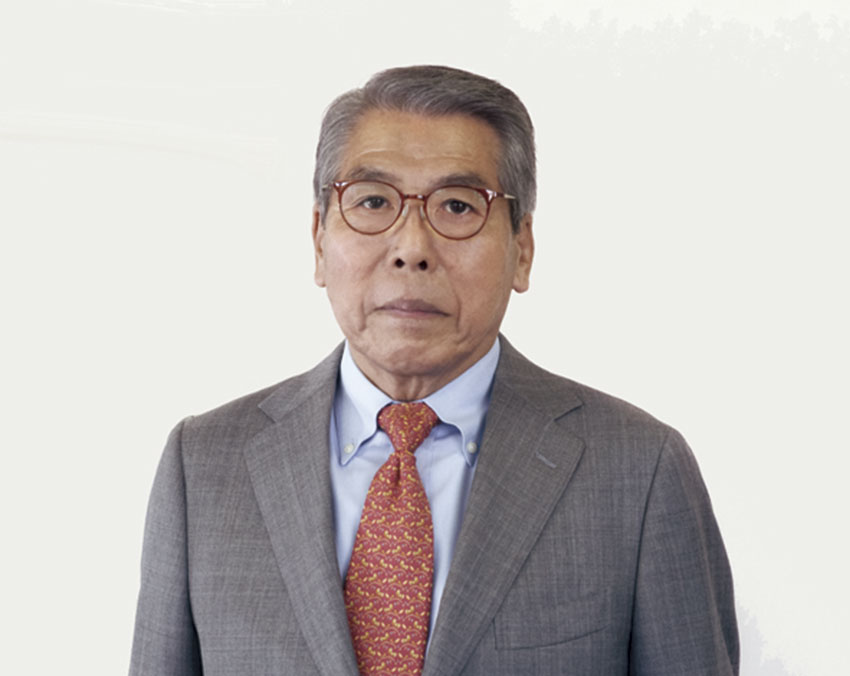

Yorioki Nara, President and CEO of NARA MACHINERY CO., LTD., which develops leading powder processing technologies for a wide range of industries, discusses the essential role of powder and granulated materials in many end-user products. He also gives more insight into NARA’s machinery and technology and its uses, such as in the production of lithium ion batteries.

Would you please tell us the role that the SMEs play in the global supply chain and specifically what role NARA MACHINERYs play as a hidden champion of Japan?

Before I answer your question, I would like to go more into the work that we accomplish here at NARA. There are three common elements of matter: gaseous, liquid, and solid. Granular material does not fit easily into one of these categories. What we are looking into is how these particle materials can be utilized and how they can be applied to provide a useful solution. When you look at the elements that are powering society, the most critical elements are actually in a powdered or granular form. Often you find that many companies are mainly focused on the end products they produce and are not focused on the important roles that the granular substances play for that end product to work. These granulated powdered materials are indispensable for any industry and that is what we at NARA focus on.

The global granulated powder processing machinery industry is expected to grow at 7% per annum reaching 22 billion USD by 2025. At the forefront of this growth are the South Asian Pacific and North American markets. As a global company would you please tell us what strategies you are implementing to take advantage of this growth overseas?

We are looking into the automobile industry as they are starting to shift into electrical and hydrogen-powered vehicles. The batteries used in these vehicles are made of a wide variety of materials but the one key material that is required is carbon or graphite. Moving forward there will be a rising demand for batteries worldwide and the countries that can export these batteries will be in a more competitive position. This is just one example of an industry that we are looking into. It would be impossible to name all of them but the point I am trying to get across is that although the battery may seem like the protagonist, the granulated materials are indispensable in creating these batteries and countless other products around the world.

NARA MACHINERY has some of the most unique machinery for producing these granulated products. What would you describe as your competitive advantage? What makes you the go-to partner when it comes to powdered technology?

When it comes to powder handling technology that is used around the world, most companies have reached a technological plateau. However, the need for more sophisticated powders is growing and I believe that our focus solely on the production and research of these granulated materials is what will keep us ahead of the pack moving forward.

You are involved in many industries such as the petrochemical, pharma, and energy industries to name a few. Would you please give us a brief overview of your core business and also the new businesses you are targeting such as the biomass industry?

Our client portfolio boasts a wide range of companies. Those that are pushing the R&D of these products and are striving to reach new stages of cutting-edge technologies, and also more traditional companies that are utilizing technologies that have been around for a hundred years because it is cheaper to do so.

The biomass sector is interesting because it is a compilation of a wide range of people’s dreams and investments in the hopes of solving a lot of environmental crises. Many countries are also quite advanced in their technologies for this segment. I think there are a lot of clients interested in this sector because it will help in the capture of massive amounts of energy and the fact that you can create value out of what looks like sludge or garbage, also makes it so interesting. This is aided also by the fact that you can invest a small amount and it has the potential of making an extremely high impact.

This industry as you mentioned is continuing to grow. Are you looking to increase your client portfolio in this biomass industry?

Yes, we have established a specific team dedicated to acquiring solely clients in the biomass industry. We have an alpha team that is in charge of the chemical, energy, and food industry and we have a second team known as the infinity team that is in charge of the biomass industry.

The biomass industry is interesting because you are creating energy out of what is essentially waste material. However, many of our clients and companies around the world have not been able to utilize this material to its full potential because of a lack of technological acumen. The biomass field up until now has mostly been in this old school train of thought where you just burn garbage. We need to further harness the know-how we have been able to gather and put it into practice so we can create clean energy that does not pollute the environment. We are looking and we are ready to work with our clients to come up with new methods or technologies to make advancements in this field.

Do you have any specific equipment designed for the biomass industry that you would like to highlight for us?

Depending on the material that is used as biomass fuel, the machinery changes, the processing changes, the techniques change. Because of this, we have to work with our clients on developing methods to process their specific biomass product. We have noticed that many of our clients work with specific materials and it represents a great challenge to us. Traditionally our machines have been on a smaller scale than is required to handle these biomass materials. This presents to us the challenge of having to increase our factory sizes as well as learn how to handle these new larger machines. These machines also are designed to handle a specific material, so essentially there may come a time where there will be a single machine per client.

You mentioned that NARA MACHINERY works with its clients in order to create new technologies or processes. Would you please tell us the role that cocreation and co-development play within your company?

Co-creation especially takes place when it comes to the biomass industry. When we receive a request from the biomass team, most of these requests involve co-creation. Precisely because of the specificity of the field and the uniqueness of the material. It also provides a mutual benefit because there is less investment involved by both parties in order to provide a greater benefit.

I would like to focus on the hybridization system NARA MACHINERY possesses. Would you please tell us the competency of using this system and what solution can you offer to your clients using this technology?

The strength of this technology is that you are working on combining more than two materials. You have two particles: the host particle and the guest particle and we have three methods in which we can combine these. The first process is what we call coating in which we coat the guest particles on to the host particles. The second is called filming. It is basically the same as coating except we melt the guest particles onto the host particles. The third would be sphereizing effect. This process uses mechanical force in order to make granular or flake material more into a sphere.

NARA MACHINERY is present in Asia, North America, and Europe. Would you please give us an overview of your international strategy?

Regarding our international strategy, we are looking to make sure that we are in contact with key companies that we can trust and have dependable partnerships with. We are not looking to focus on penetrating any specific market. Frankly speaking, we do not have that kind of manpower.

From that perspective, though the partnerships that we have may not be numerous, the partnerships that we have developed are with those that have understood the benefits of the hybridization system, and that it is a system that can be applied for a multitude of solutions.

To find your clients, do you go through distributors or do you directly contact them?

We only work through direct partnerships and our clients also prefer that type of relationship. Especially when it comes to the hybridization technology. Unless our clients directly communicate with us, there can be misunderstandings on how this system could be of use to them.

You mentioned that your international strategy is affected by your lack of manpower. This situation is playing itself out throughout other Japanese companies as well. What is NARA MACHINERY doing to overcome this obstacle?

In terms of the offices we keep globally, we do not have the capability of continuing to open more offices and sending our valuable staff to get those offices operational. However, we do have a solid presence in Germany where most of our engineers are German and of other nationalities.

What would you like the brand NARA MACHINERY to stand for?

When it comes to NARA our hybridization system is our star player, and this is the technology that we would like to be known for. But we have other technologies available as well that are worthy of mentioning. For example, our powder handling technology has great potential and has a variety of applications and uses in terms of co-creation and R&D.

As the president of NARA, what are your aspirations for the company?

In terms of our aspirations, we aren’t looking for any new strategies or technologies but rather for other companies to recognize our brand and come to us for any solutions that they may need. There are four large exhibitions in Japan that we would like to attend and hopefully be successful at spreading our name there.

With regards to Europe we have a sales office in Germany. Also we have 2 licensees in the US. However, we do not have any offices in Southeast Asia, so my dream would be to have established a presence in that market.

0 COMMENTS